Получить бесплатное предложение

"*"обозначает обязательные поля

Модель: CFCM-30ES-30EH

Станок для формования углов

Станок холодного формования углов

Станок для формования углов

Модель: CFCM-30ES / CFCM-30EH

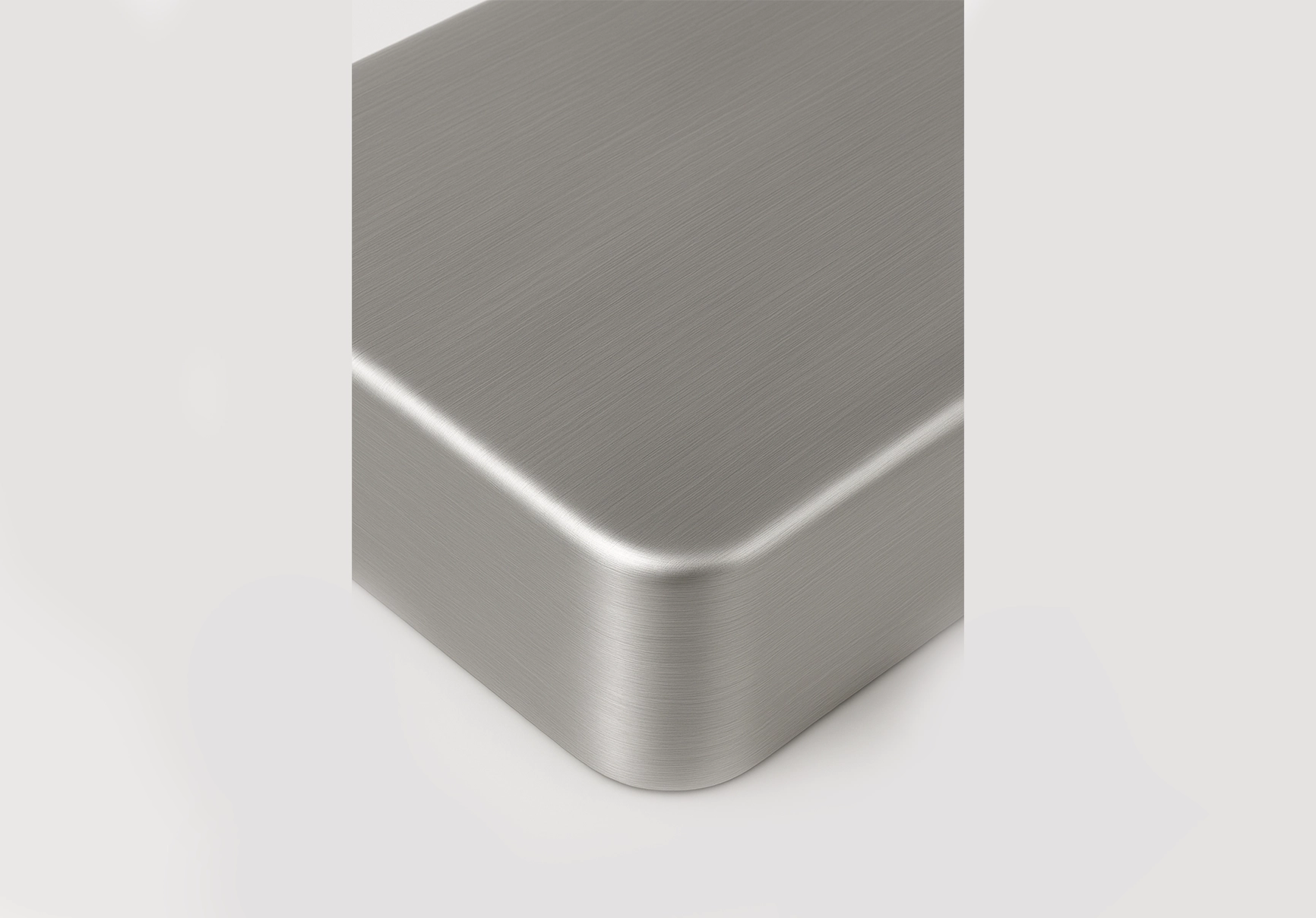

Станок для формования углов является решением без сварки для производства бесшовных и идеально равномерных углов из листового металла. Используя точный процесс холодного формования, данное оборудование исключает сварку, шлифование и полировку, значительно сокращая время производства и снижая затраты.

Разработанный для высокой повторяемости и длительного промышленного использования, станок обеспечивает идентичную геометрию углов, высокую прочность и чистый внешний вид, что делает его идеальным выбором для современных линий обработки листового металла.

ВВЕДЕНИЕ

ТЕХНИЧЕСКАЯ ИНФОРМАЦИЯ

Станок для формования углов: революция в производстве углов из листового металла

В сфере обработки листового металла достижение точных и равномерных металлических углов является важнейшей задачей. Традиционные методы включают трудоёмкий многоэтапный процесс, который состоит из резки, гибки, сварки, шлифования и полировки. Этот обширный процесс не только занимает много времени, но и требует значительных затрат. Станок для формования углов PAYAPRESS (CFCM-30ES / CFCM-30EH) кардинально меняет способ формирования углов, исключая необходимость сварки и полировки, значительно сокращая время производства и затраты при обеспечении стабильных и высококачественных результатов.Ключевые особенности станка для формования углов

- Высокая точность: Серия CFCM использует передовые технологии формования для создания бесшовных и эстетически совершенных углов с высокой повторяемостью.

- Универсальность: Способен работать с различными толщинами листового металла и формировать углы с различными радиусами, что делает его подходящим для широкого спектра применений.

- Надёжность: Изготовлен из высокопрочных материалов и имеет современный промышленный дизайн, обеспечивающий непрерывную работу на протяжении многих лет.

- Простота эксплуатации: Доступен в ручных и автоматических версиях для разных толщин листа, обеспечивая гибкость и удобство для оператора.

Преимущества использования станка для формования углов

Станок для формования углов PAYAPRESS значительно повышает скорость производства за счёт исключения сварки, шлифования и полировки. Он обеспечивает высокий уровень стабильности качества, поскольку каждый угол формируется с высокой точностью. Это приводит к снижению трудозатрат и минимизации отходов, так как ручные операции по сварке и полировке не требуются. Гибкость оборудования позволяет выполнять индивидуальные гибы и проектировать специальные штампы, удовлетворяя широкий спектр требований клиентов.Максимальная эффективность

Одной из ключевых особенностей данного оборудования является возможность производить высококачественные углы за значительно меньшее время по сравнению с традиционными методами. Благодаря точному процессу формования и возможности быстрой замены штампов пользователи могут получать стабильные результаты без риска человеческих ошибок. Независимо от того, производите ли вы Z-образные гибы или специальные формы, данный станок обеспечивает высокую точность и эффективность.Настраиваемые штампы для различных применений

Наш станок для формования углов оснащён различными вариантами штампов, которые могут быть адаптированы под конкретные требования проекта. Наиболее популярные типы штампов включают:- Штамп Z-образной формы: Предназначен для создания точных Z-образных гибов, широко применяемых в промышленности.

- Штамп для гибки кромки: Идеален для формирования кромок листового металла, обеспечивая гибкость по форме и размерам.

- Штамп для скручивания: Используется для создания скрученных форм токопроводящих шин в специализированных применениях.

Технические характеристики

Заключение

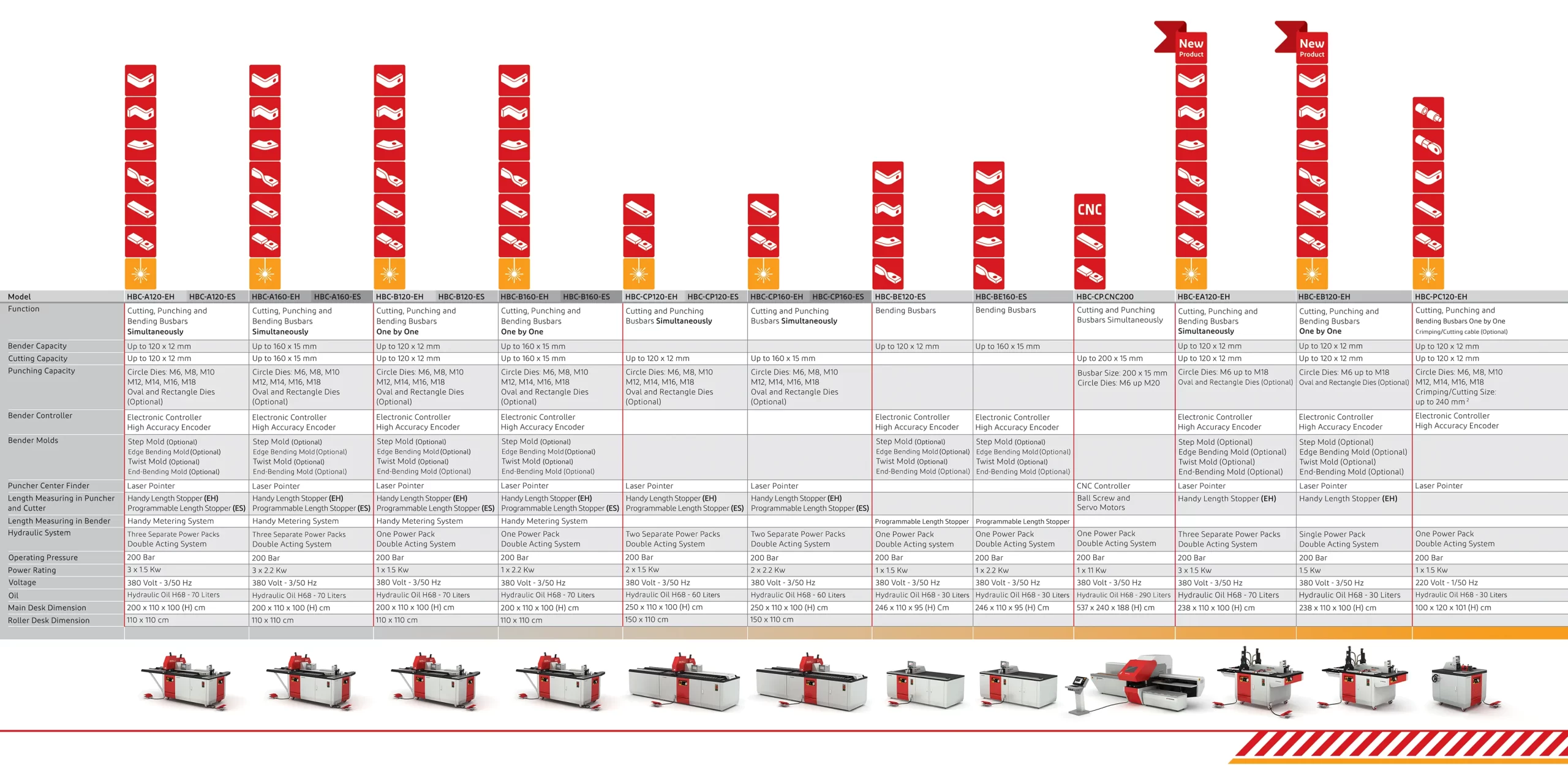

Станок для формования углов PAYAPRESS является инновационным решением в отрасли обработки листового металла. Он устраняет дорогостоящие и трудоёмкие этапы, такие как сварка, шлифование и полировка, предоставляя производителям более быстрый и эффективный способ получения качественных и одинаковых металлических углов. Благодаря возможности настройки штампов и высокой точности формования, данное оборудование обеспечивает непревзойдённую гибкость и становится ценным дополнением для любого производственного предприятия.| Модель | CFCM-30EH | CFCM-30ES |

|---|---|---|

| Система изменения настроек станка в зависимости от толщины листа | Ручная | Автоматическая |

| Габаритные размеры | 1420 × 1200 × 1850 мм | 1420 × 1200 × 1850 мм |

| Диапазон толщины | 0,5 до 2 мм | 0,5 до 2 мм |

| Допустимая толщина листа (масляный) — ST12 | 0,8 до 2 мм | 0,8 до 2 мм |

| Допустимая толщина листа (чёрный) — ST37 | 1,5 до 2 мм | 1,5 до 2 мм |

| Допустимая толщина листа — нержавеющая сталь | 0,8 до 2 мм | 0,8 до 2 мм |

| Диапазон радиуса формования | 6 до 30 мм | 6 до 30 мм |

| Минимальный размер заготовки | 210 × 210 мм | 210 × 210 мм |

| Вес основного устройства | 1200 кг | 1200 кг |

| Общая мощность | 4,5 кВт | 4,5 кВт |

| Максимальное гидравлическое давление | 200 бар | 200 бар |

| Общая мощность двигателя | Electrogen 1 × 4 кВт | Electrogen 1 × 4 кВт |

| Размер HMI | 7 дюймов | 7 дюймов |

| PLC | Delta | Delta |

| Ёмкость гидравлического бака | 50 литров | 50 литров |

| Соединение труб | RN | RN |

| Уплотнения | Kastas | Kastas |

| Гидравлический клапан | Tork Hydraulics | Duplomatic |

| Гидравлический насос | Arafan | Arafan |

| Датчик | Autonics | Autonics |

| Коды управления | Raad | Autonics |

| AC-контактор | Hyundai | Schneider |

НАЙДИТЕ СВОЁ РЕШЕНИЕ

FAQ's

Часто задаваемые вопросы

Что такое станок для формования углов?

Станок для формования углов представляет собой специализированное оборудование, предназначенное для формирования углов листового металла без необходимости сварки, шлифования или полировки. Он обеспечивает бесшовные и высококачественные углы с высокой точностью и скоростью, что делает его идеальным решением для обработки токопроводящих шин и других процессов изготовления изделий из листового металла.

Каковы преимущества использования станка для формования углов?

Основные преимущества использования станка для формования углов включают повышение скорости производства, снижение затрат на рабочую силу и значительное уменьшение отходов материала. Кроме того, оборудование обеспечивает стабильные и равномерные результаты, повышая общее качество металлических углов при массовом производстве.

Может ли станок для формования углов работать с различной толщиной листового металла?

Да, станок для формования углов может работать с различной толщиной листового металла от 0,5 мм до 2 мм в зависимости от модели (CFCM-30EH с ручной настройкой и CFCM-30ES с автоматической регулировкой). Такая универсальность позволяет эффективно обрабатывать широкий спектр материалов.

Возможно ли изготовление станка для формования углов с настройкой под различные формы и радиусы?

Да, станок оснащён настраиваемыми штампами, которые позволяют производить углы различных форм, включая Z-образные, гибку кромок и скручивающие формы. Такая гибкость обеспечивает возможность удовлетворять индивидуальные требования заказчиков и изготавливать высоко персонализированные металлические углы.

Каков ожидаемый срок службы станка для формования углов?

Благодаря прочной промышленной конструкции, использованию высокопрочных материалов и низким требованиям к обслуживанию, станок для формования углов рассчитан на многолетнюю непрерывную эксплуатацию. Он разработан с учётом интенсивных условий работы и обеспечивает долгосрочную надёжность и долговечность.

Нужна

консультация?

Свяжитесь с нами и

задайте свой вопрос.

"*"обозначает обязательные поля