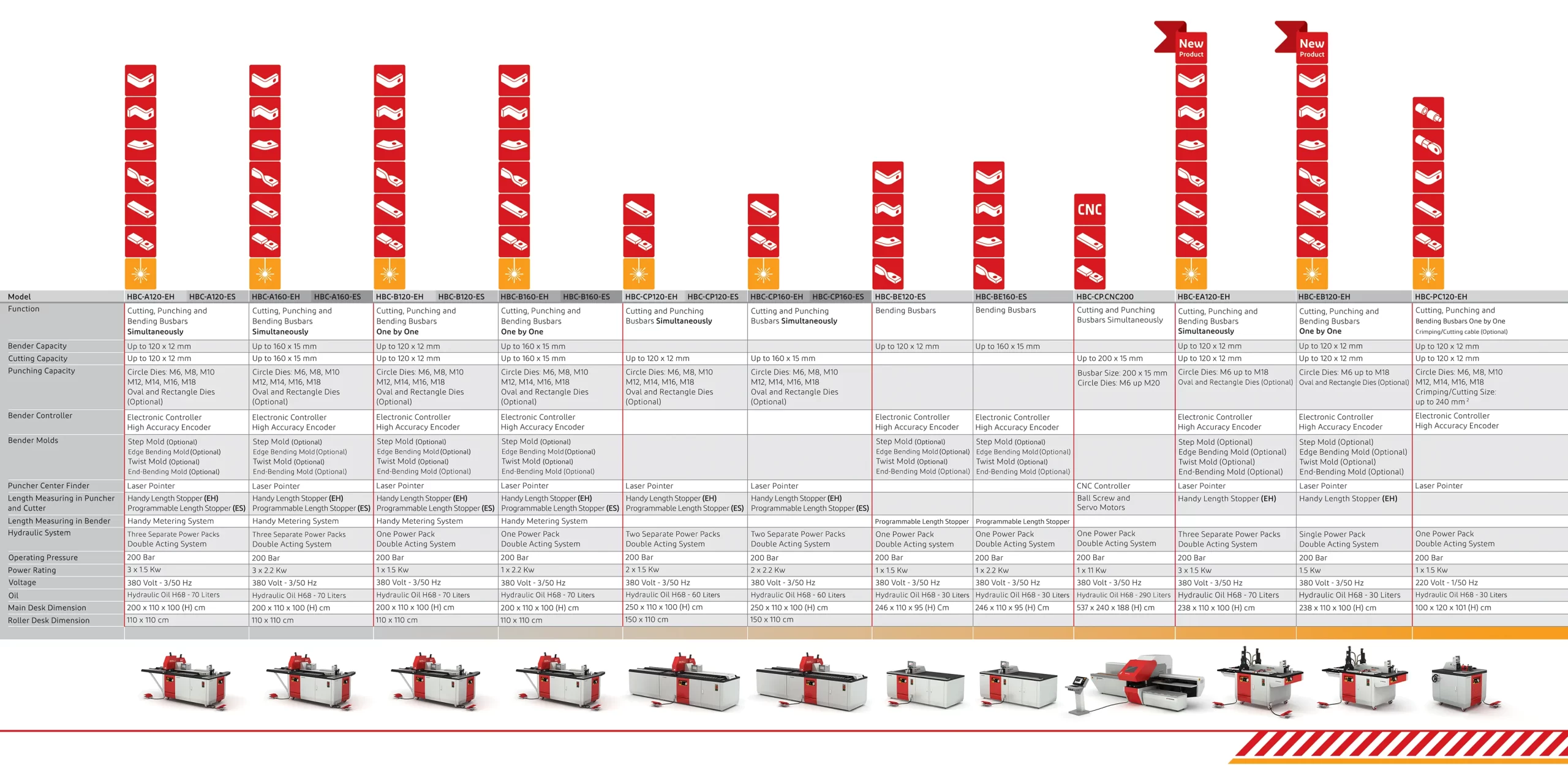

Bender station

To bend copper busbars up to 160*15 mm one by one

Digital controller for bender

To give instructions to the bender station to reach to perfect results

Digital controller for puncher and cutter

To give instructions to the puncher and cutter station to reach to perfect results

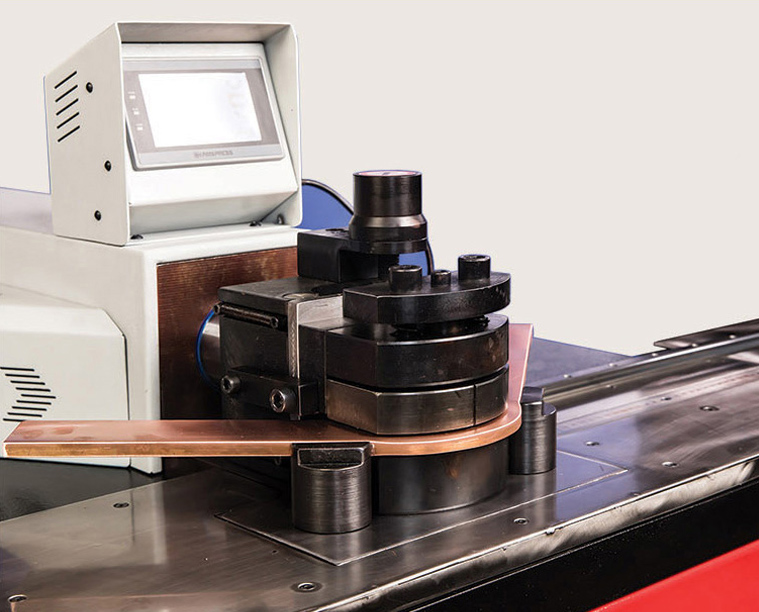

Puncher station

To punch copper busbars up to 160*15 mm one by one

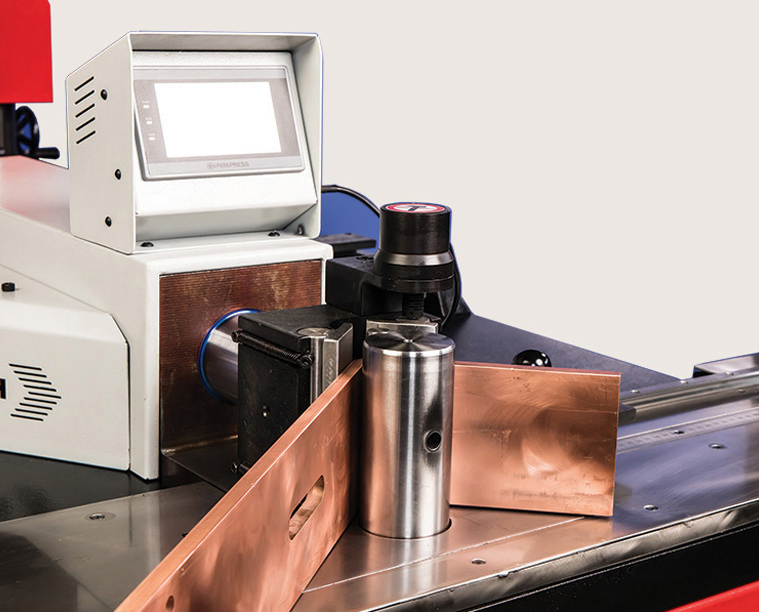

Hydraulic Power Pack

Equipped with one power pack

Get a Free Technical Quote

"*"обозначает обязательные поля

Model: HBC-B120 ES/EH

Busbar Bender & Cutter & Puncher Machine

3 in 1 Electrical Busbar Machine

Electrical Bus Bar Processing Machine

This machine is mostly for users which are looking for a suitable busbar machine with an economic price that could help them with the Punching, Cutting and Bending aluminum and copper busbars. The only difference between this machine with the Type A (HBC-A120) is that this device is equipped with only one power pack which means that the operator could only operate on one station at a time.

INTRODUCTION

TECHNICAL INFORMATION

Busbar Machine HBC-B120 Features

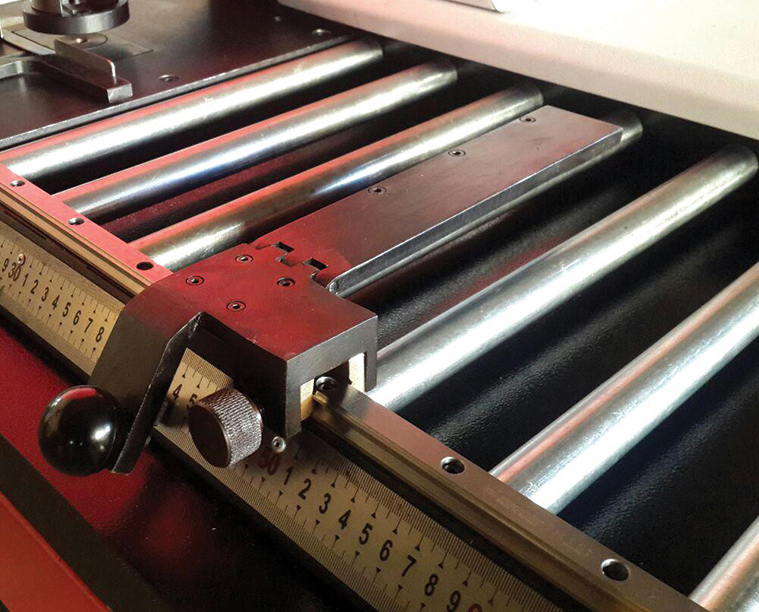

This device is equipped with a longitudinal digital ruler (linear encoder) in the bending section, which measures the displacement of the bending piston in each bending process is measured and by repeating it, you will be able to create bends of the same shape on the busbar. Also, this device is equipped with a spring back compensation system to create very precise bends. On the other hand, the cutting station of this device is equipped with center oriented guide that leads to the best result. This machine is capable of doing all of the main three processes (punching, cutting, bending) up to 12 × 120 mm but one by one. The machine’s puncher station is equipped with a laser center finder (Laser Pointer) and, upon request, in machines equipped with programmable length stopper, It can be programmed (can be programmed in the X and Y axis in the puncher and can be programmed in the Y axis in the cutter). This busbar machine is also equipped with the 4.0 industry technology which makes the possibility of connecting to the internet and getting feedback from every process at any time of the device.

Technical details

1- Copper puncher and cutter station

The device in the puncher and cutter section is optionally equipped with programmable length stopper with the ability to save points required in a panel for the punching part along the X and Y axis as well as in the Y axis in the cutter station. Thus, by installing this option, there is no need to draw lines and points on copper busbars, also by reducing the operator’s intervention, human error in accuracy will be minimized. Also designing and manufacturing laser pointer in the puncher station of the device. increases the speed of the operation and the accuracy of the punching process, which the Payapress busbar processing machines have this capability along with the worldwide standards.

2- Bending Station

The bender of this device is equipped with two independent systems to achieve bending with high precision and repeatability to repeat bending process in a high number of times.

1-Rotary measuring system:

A rotary encoder with a pulse factor of 3600 pulses per revolution in couple is directly connected to the movable rotating plates of the bender. Since these plates are attached to the back of the busbar and rotates with it while bending process, the amount of rotation is directly transferred to the encoder (5 Pulses each degree), Then, the bender controller system is online to adjust the bending amount and after reaching the desired bending angle, it ends the process.

2-Linear measuring system:

A digital ruler consists of a magnetic strip and a digital receiver attached to the end of the piston rod measures and controls the advance rate of the piston in each bending process. This system provides bend repeatability with an accuracy of 5 microns, which can lead to same size and numerous bends. It is also possible for the operator that instead of entering the angle from the beginning, enter the stroke length on the device screen. It should also be noted that the roller plate installed in the movable jaw section of the bender rotates dynamically during bending along with the busbar, which this design advantage prevents the bottom surface from being stretched. The busbar moves forward on other surfaces and creates a line on the underside of the busbar during bending. Among the other features of the bending section, it is possible to install a rod with different radii on the fixed jaw of the bender, which makes the bending arc more accurate in different thicknesses.

Sure! Here’s the translation:

To learn more about the concept of busbars and their applications in electrical systems, you can refer to the detailed explanation available on Wikipedia. This information can help you gain a better understanding of the fundamentals and applications of busbar processing machines.

| HBC-B120-EH | HBC-B120-ES | MODEL |

|---|---|

| Cutting ,Punching and Bending Busbars One by One | Function |

| Up to 120 x 12mm | Bender capacity |

| Up to 120 x 12mm | Cutting capacity |

| Circle Dies: M6 up to M18 Oval and Rectangle Dies (Optional) | Punching capacity |

| Electronic Controller High Accuracy Encoder | Bender controller |

| Step Mold (Optional) Edge Bending Mold (Optional) Twist Bending Mold (Optional) End-Bending Mold (Optional) | Bender Molds |

| Laser Pointer | Puncher center finder |

| Handy Length Stopper (EH) Programmable Length Stopper (ES) | Length measuring in puncher and cutter |

| Three Separate Power Packs Double Acting System | Hydraulic system |

| 200 Bar | Operating pressure |

| 1 x 1.5 Kw | Power rating |

| 380 volt — 3/50 Hz | Voltage |

| Hydraulic Oil H68 — 70 Liters | Oil |

| 200 x 110 x 100 (H) cm | Main desk dimension |

| 110 x 100 cm | Roller desk dimension |

FIND YOUR BUSBAR SOLUTION

FAQ's

Frequently asked questions

Can all of the stations work at the same time on this device?

No, on this device operators cannot work on each station at the same time because this device is equipped with only one power pack. And that is the main difference between this device and HBC-A120.

What kind of bending molds does it have?

The difference between these machines is their capacity of processing on busbars, HBC-B120 is able to get used to process busbars up to 120 × 12 mm while HBC-B160 maximum busbar size is 160 × 15 mm.

What kind of punching dies does it have?

Circle dies are from M6 up to M18, Oval and rectangular dies are optional and can be made by the customer’s order.

How much is the price?

For gaining more information about the price contact the sales department.

What is the bending accuracy of the device?

Payapress will provide you with bending machines that are equipped with a rotary encoder with a pulse

factor of 3600 pulses per revolution in couple that is directly connected to the movable rotating plates of

the bender.

NEED

CONSULTATION?

Feel free to contact us and

ask your question, its absolutely free.

"*"обозначает обязательные поля