1

Quick tool change

Easy tool change to get to results faster

2

Power button

It is used to Turn On/Off the Machine.

3

Hydraulic power pack

To generate power to the device

4

Foot Pedal

It is used to move the hydraulic arm back-forward and to make operation on automatic mode

견적 받기

"*" indicates required fields

모델: HBC-BE160 ES/EH

버스바 벤딩 머신

전기 버스바 벤더 머신

버스바 벤딩 머신

버스바 벤딩 머신은 당사의 버스바 머신 중 하나입니다. 아시다시피 버스바를 벤딩하는 작업은 스위치기어 제조에서 매우 중요한 역할을 합니다. 우선, 스위치기어용 버스바를 벤딩하면 구리 사용량을 줄일 수 있어 제작 비용 절감에 도움이 됩니다. 또한 전기적 손실을 줄이고 전기 패널의 외관 품질을 향상시키는 것도 버스바 벤딩의 중요한 이유입니다. 이처럼 버스바 벤딩은 이 산업에서 매우 중요한 작업이며, PAYAPRESS의 전문 버스바 벤딩 머신은 알루미늄 및 구리 버스바를 다양한 형태로 가공할 수 있도록 설계되었습니다. 이 버스바 벤딩 머신은 최대 15 × 160 mm 크기의 버스바를 벤딩할 수 있으며, 이는 이 산업에서 가장 널리 사용되는 규격 중 하나입니다. HBC-BE160은 다양한 옵션을 제공하여 합리적인 시간 내에 높은 정밀도로 여러 형태의 벤딩을 수행할 수 있도록 지원하며, 아래에서 자세히 설명됩니다. 이 장비의 벤딩 스테이션은 두 개의 독립적인 시스템을 갖추고 있어 높은 정밀도와 반복성을 제공하며, 대량 생산에서도 동일한 품질의 벤딩을 반복 수행할 수 있습니다.소개

기술 정보

버스바 벤딩 머신 특징

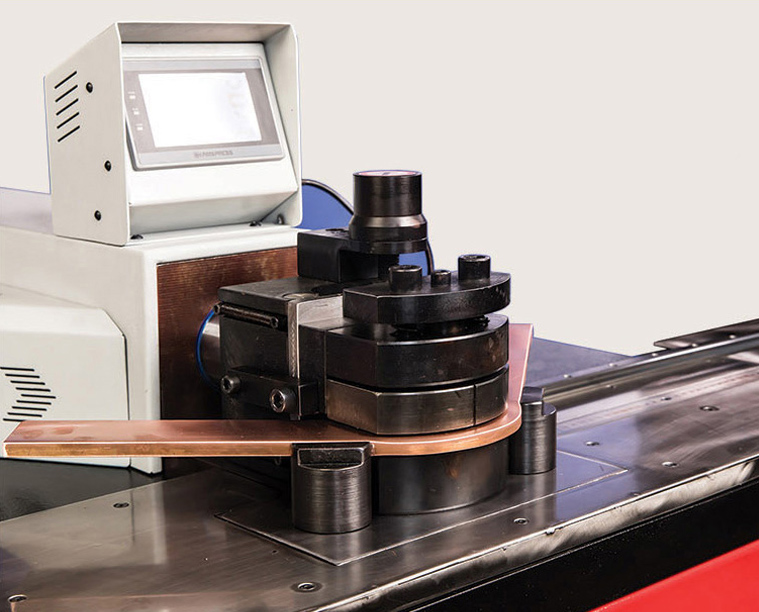

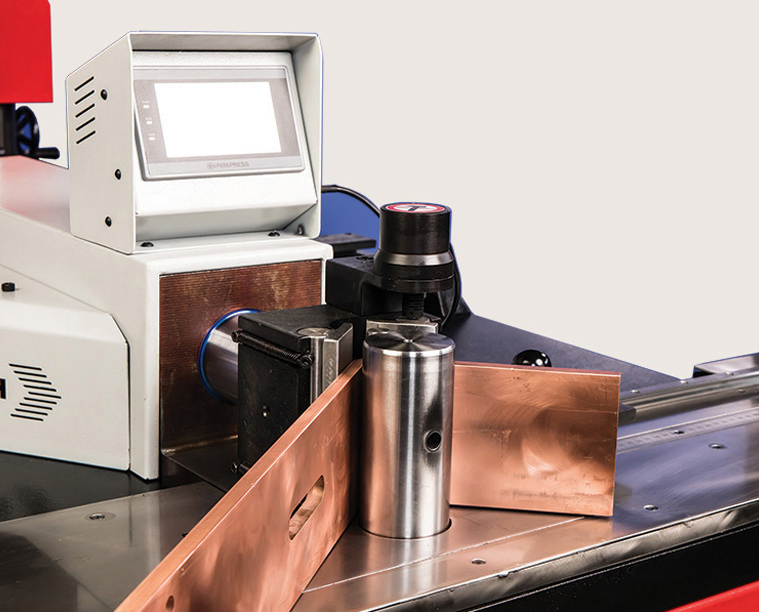

1- 회전 측정 시스템: 버스바 벤딩 머신은 당사의 버스바 머신 중 하나입니다. 3600펄스/회전의 펄스 계수를 가진 로터리 엔코더가 벤더의 이동식 회전 플레이트에 직접 연결되어 있습니다. 이 플레이트는 벤딩 과정에서 버스바와 함께 회전하므로, 회전량이 엔코더로 직접 전달됩니다(각도당 5펄스). 이후 벤딩 컨트롤러 시스템이 실시간으로 벤딩량을 조정하며, 원하는 각도에 도달하면 자동으로 공정을 종료합니다. 2- 선형 측정 시스템: 자기 스트립과 디지털 수신기로 구성된 디지털 측정 장치는 피스톤 로드 끝에 설치되어 각 벤딩 과정에서 피스톤의 전진 속도를 측정하고 제어합니다. 이 시스템은 최대 5마이크론의 반복 정밀도를 제공하여 동일한 크기의 벤딩을 반복적으로 수행할 수 있습니다. 작업자는 각도 입력 대신 장비 화면에서 직접 스트로크 길이를 입력할 수도 있습니다. 또한, 벤더의 이동식 조 부분에 설치된 롤러 플레이트는 벤딩 중 버스바와 함께 동적으로 회전하여 하부 표면의 늘어남을 방지합니다. 이 설계는 표면 손상이나 자국 생성을 최소화합니다. 벤딩 섹션의 또 다른 장점으로, 고정 조에 다양한 반경의 로드를 장착할 수 있어 다양한 두께에서 더욱 정확한 벤딩 곡률을 구현할 수 있습니다. 1- 트위스트 벤딩 금형 일부 경우 버스바가 설치 위치와 정렬되지 않아 연결이 어려운 상황이 발생합니다. 이러한 경우 많은 사용자가 여러 개의 버스바를 사용하여 연결을 해결합니다. PAYAPRESS의 해결책은 “트위스트 벤딩 금형”으로, 10 × 60 mm 버스바의 방향을 최대 90도까지 회전할 수 있어 특수한 적용에 매우 유용합니다. 이 금형은 PAYAPRESS 버스바 머신에 장착할 수 있습니다. 2- 엣지 벤딩 금형 다양한 폭과 두께의 버스바를 사용하는 경우, 서로 직각으로 두 개의 버스바를 사용하는 대신 하나의 버스바를 최대 90도까지 엣지 벤딩하여 공간과 자재를 절감할 수 있습니다. 3- Z형 금형 일부 응용에서는 매우 짧은 간격으로 두 번의 벤딩이 필요합니다. 일반적인 버스바 벤딩 머신은 “벤딩 롤러” 사용으로 인해 약 60mm의 최소 간격 제한이 있습니다. 전기 패널 설계 과정에서 더 짧은 간격의 벤딩이 필요한 경우, 더 높은 효율의 금형이 필요하며 이를 “Z형 금형”이라고 합니다.| HBC-BE160 ES | 모델 |

|---|---|

| 버스바 벤딩 | 기능 |

| 최대 160 × 15 mm | 벤딩 용량 |

| 전자식 컨트롤러 고정밀 엔코더 |

벤더 컨트롤러 |

| 스텝 금형 (옵션) 엣지 벤딩 금형 (옵션) 트위스트 금형 (옵션) 엔드 벤딩 금형 (옵션) |

벤딩 금형 |

| 프로그래머블 길이 스토퍼 | 벤딩 길이 측정 |

| 단일 파워팩 더블 액팅 시스템 |

유압 시스템 |

| 200 Bar | 작동 압력 |

| 1 × 2.2 kW | 정격 출력 |

| 380 Volt – 3/50 Hz | 전압 |

| 유압 오일 H68 – 30 리터 | 오일 |

| 130 × 110 × 100 (H) cm | 메인 테이블 크기 |

솔루션 찾기

자주 묻는 질문

자주 묻는 질문

귀사의 결제 조건은 무엇입니까?

고객님의 결제 방식을 반영하여 최상의 서비스를 제공할 수 있도록 유연하게 협의할 준비가 되어 있습니다.

주문에 따라 장비에 옵션을 추가할 수 있습니까?

고객님께서 보내주시는 주문 사항과 도면에 따라 요청하신 장비를 맞춤 제작할 수 있습니다.

최소 주문 수량은 얼마입니까?

최소 주문 수량은 1세트입니다. 당사의 고객은 최종 사용자, 유통업체 및 도매업체 모두 포함됩니다.

기계의 모든 라벨과 사용 설명서는 영어로 제공됩니까?

네. 기계의 모든 라벨과 사용 설명서는 영어로 제공됩니다.

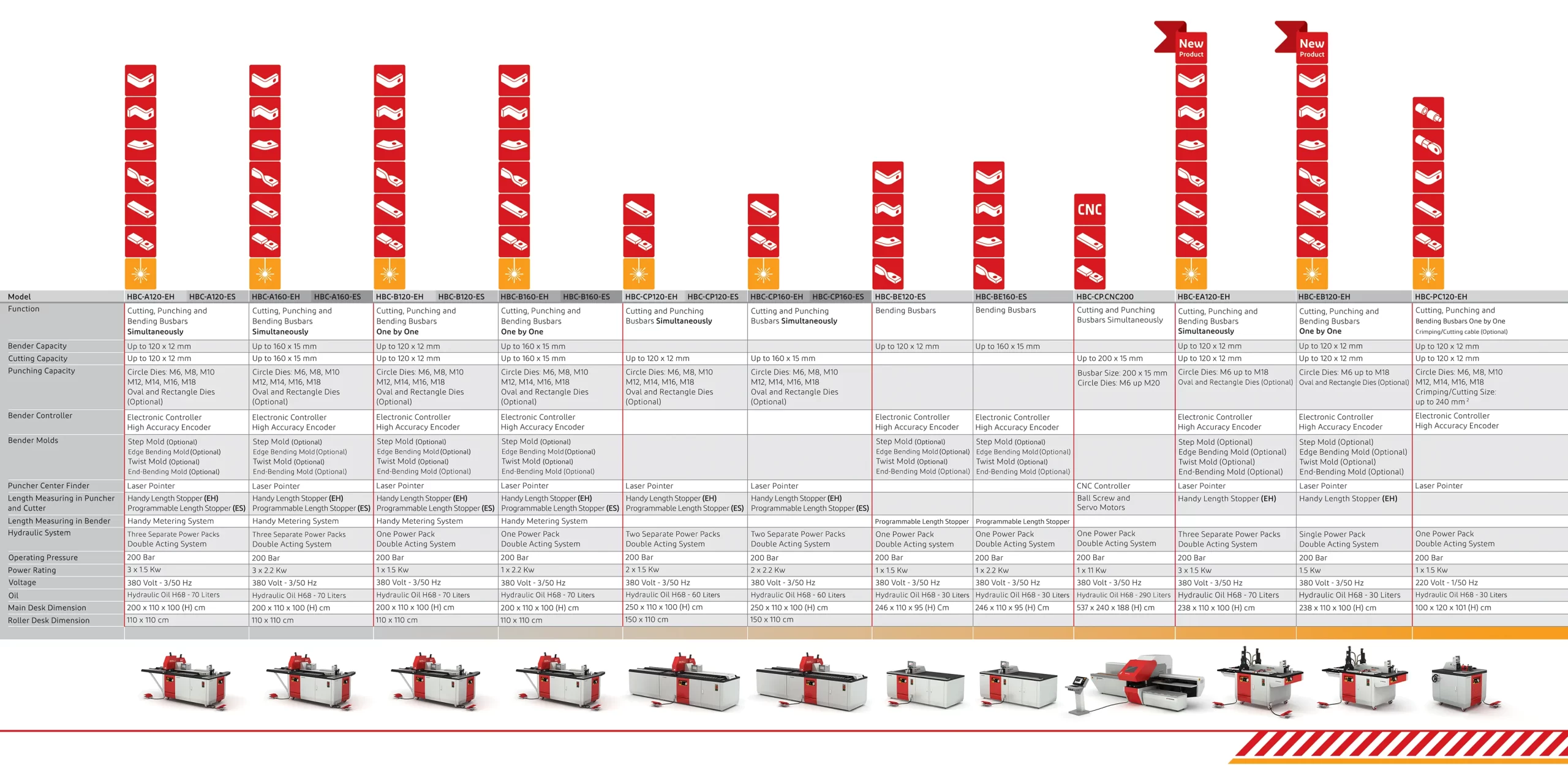

귀사의 장비 제품군은 얼마나 다양합니까?

당사는 다양한 버스바 장비 라인업을 보유하고 있으며, 고객의 요구에 따라 다른 장비도 맞춤 제작할 수 있습니다.

무료 견적 받기

상담이

필요하신가요?

편하게 문의해 주세요.

질문은 완전히 무료입니다.

"*" indicates required fields