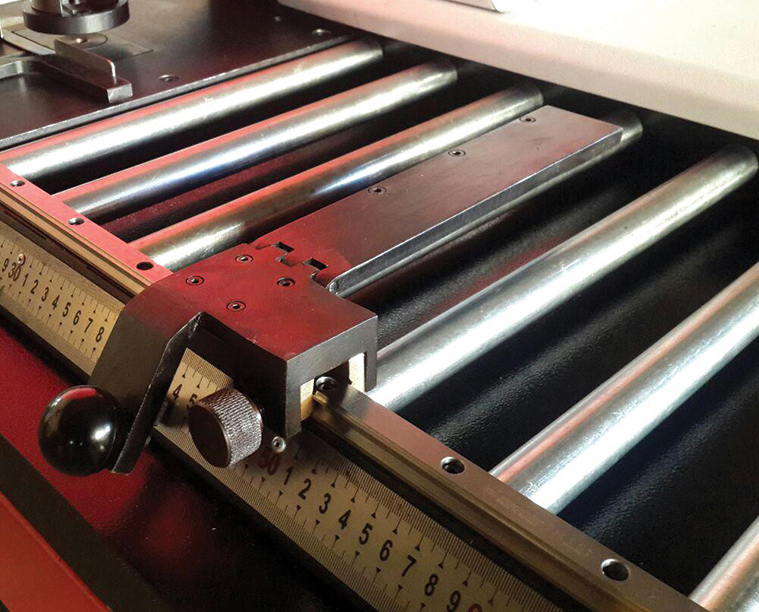

Rollers

Rollers at two side of the puncher for ease of busbar movement

Foot Pedal

It is used to move the hydraulic arm back-forward and to make operation on automatic mode

Puncher station

To punch copper busbars up to 160*15mm simultaneously

Cutter station

To punch copper busbars up to 160*15mm simultaneously

"*" gerekli alanları gösterir

Model: HBC-CP120 ES/EH

Busbar Cutting Machine & Busbar Punching Machine

Busbar Punch Cutting Machine

Copper Punching and Copper Cutting Machine

Having this machine in your workshop means that you can have both the busbar punching machine and busbar cutting machine in one device. With the help of this punch-cutting machine, you will have the best results without having any fractions on your busbars. Let’s take a deeper look through the cutting section of this copper punching and cutting machine first. In the cutting process, the maximum size you can perform for the busbar is 12 x 120 mm. If you use a larger size busbar, it may damage the operator as well as break the cutting blade. In the punching process, the maximum busbar size that can be obtained is 12 x 120.

If you use a larger size busbar, it may cause damage to the operator as well as damage to the punch section.

INTRODUCTION

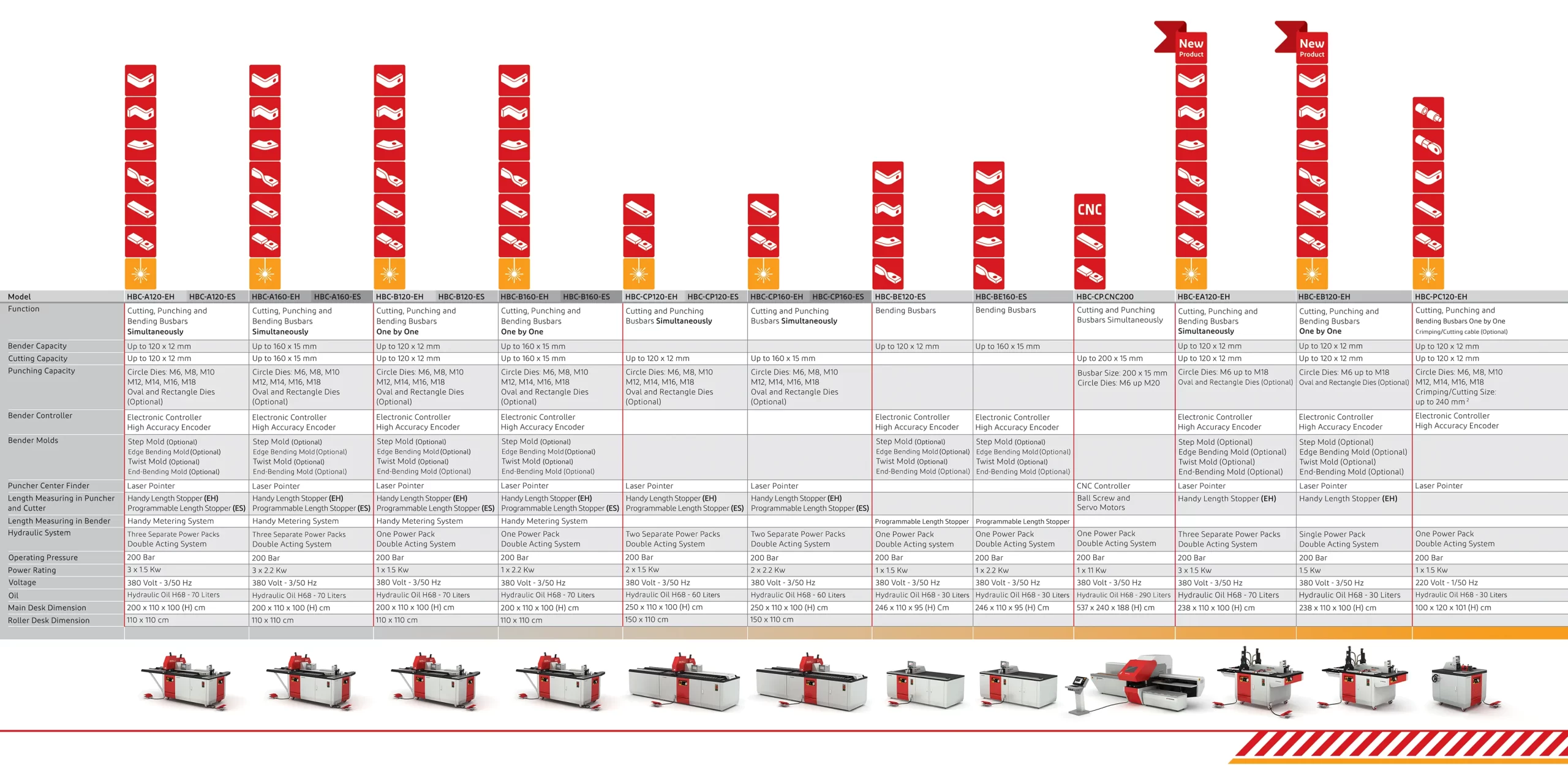

TECHNICAL INFORMATION

Busbar Punch Cutting Machine Features

Metering systemsA) Handy metering systemThis metering system is already installed on the device with a very high precision adjustment.B) Programmable metering systemOne of the greatest features in this section that is optional, and could make this device even more user-friendly is the “Programmable metering system”, which helps you to have a very high accuracy in positioning of cuts. The programmable metering system in the cutting section is capable to be programmed in absolute and incremental positions which is up to 20 positions. Also “Rollers” at two sides of the cutter, make the busbar movement pretty easy.Punching Male and Female diesThe male and female dies are the main tools for punching and they are one of the most important and practical equipment of metal products and are made in different models. In all of them, the punching operation is done by two parts, the Male and female die, which punches the desired special shape from the raw sheet (Busbar).Cutter and Puncher Indicator Control PanelThese panels are installed in both directions of the cutter and the puncher, and the relevant panel performs the manual and automatic movement of the longitudinal position of the cutter as well as the longitudinal and transverse position of the puncher.Copper punching diesThis device includes “Circle dies” from the size: M6 up to M18 also “Oval and rectangle dies” which are optional and can be made by customer’s order.MODEL | HBC-CP120-EH | HBC-CP120-ES |

|---|---|

| Function | Cutting and Punching Busbars Simultaneously |

| Cutting Capacity | Up to 120 x 12 mm |

| Punching Capacity | Circle Dies: M6 up to M18 Oval and Rectangle Dies (Optional) |

| Puncher Center Finder | Laser Pointer |

| Length Measuring in Puncher and Cutter | Handy Length Stopper (EH) Programmable Length Stopper (ES) |

| Hydraulic System | Two Separate Power Packs Double Acting System |

| Operating Pressure | 200 Bar |

| Power Rating | 2 x 1.5 Kw |

| Voltage | 380 Volt – 3/50 Hz |

| Oil | Hydraulic Oil H68 – 60 Liters |

| Main Desk Dimension | 250 x 110 x 100 (H) cm |

| Roller Desk Dimension | 150 x 110 cm |

FIND YOUR SOLUTION

FAQ's

Frequently asked questions

What types of busbars could be used to perform on with this device?

This device is capable to perform operations on copper and aluminum busbars.

What is the maximum Busbar size for this device?

This device is capable to perform operations on copper and aluminum busbars.

What types of punching dies this device includes?

“Circle dies” from the size: M6 up to M18/ Oval and rectangular dies are Optional.

How precise is the bending station?

Spring back compensation system and a 3600 pulse encoder with 5 micron accuracy leads to perfect bending results.

What is the power rating of this device?

The power rating of this device is 1 × 11 Kw.

NEED

CONSULTATION?

Feel free to contact us and

ask your question, its absolutely free.

"*" gerekli alanları gösterir