Hydraulic power pack

To generate power to the device

Power button

It is used to Turn On/Off the Machine.

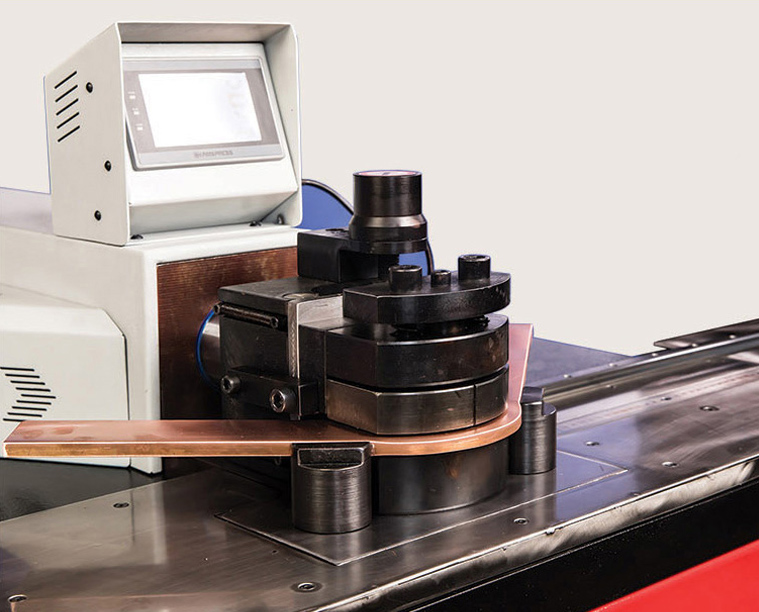

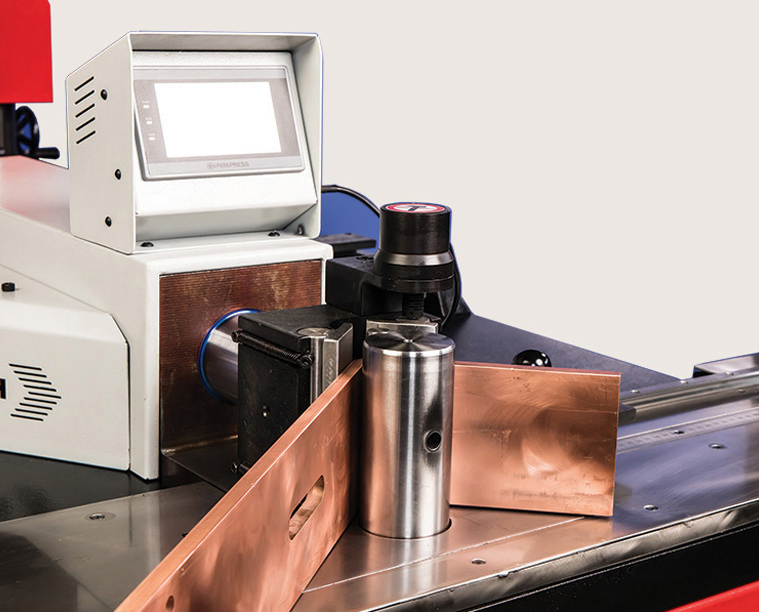

Quick tool change

Easy tool change to get to results faster

Foot pedal

It is used to move the hydraulic arm back-forward and to make operation on automatic mode

Model: HBC-BE120 ES

Copper Busbar Bending Machine

Electrical Busbar Bender Machine

Busbar Bending Machine

The purpose of this device is bending copper and aluminum which makes it an easier job for all of its users.

This device is capable of bending copper and aluminum busbars up to 120 ×12 mm. Bender controller equipped with Double acting hydraulic system and a spring back compensation system, Digital bending indicator, and a high precision encoder and rotatable plates allow its users to make perfect bending results without having any fractions on their final product. This machine is very suitable for switchgear and control panel builders to proceed with their work in the fastest way possible. High precision and high speed are the most remarkable elements of this device. One of the most popular bending shapes in this industry is the “Z-shape mold” which its purpose is to create too close bends and in this device only in one stroke. This mold can be designed in different sizes by the customer’s order. With “Edge bending mold” you can bend busbars from the edge side which is obvious by its name! and the Busbar size limit for this mold is 40 × 10 mm up to 90 degrees and 50 × 10 mm up to 45 degrees. Another mold is the “Twist bending mold” which is to twist busbars for special purposes and the busbar size limit for this mold is 60 × 10 mm up to 90 degrees. All of the above introduced bending molds are optional and can be made for customers by order.

INTRODUCTION

TECHNICAL INFORMATION

Busbar Bending Machine Features

A rotary measurement system with 3600 pulses per round in a form of a couple is directly connected to the movable rotating plates of the bender. Since these plates are attached to the back of the busbar and are rotating with it during the bending operation, the amount of rotating will be transferred directly to the encoder (5 pulses per degree) then the bending controller system calculates the degree of the bending online and end the process after reaching the desired bending angle.

The PLC and Motors used in this machine are from the brand “Siemens” which makes this device more sufficient and well-found. Two metering systems can be used for this device and one of them is a Handy metering system with high accuracy adjustment that is already installed on the device. The second one is programmable metering system which is optional and by using it operator will be able to calculate the stroke length and use the obtained number to operate the same bend on a number of busbar coppers. With the help of the “Bender panel” you can simply enter your desired angle into it and after saving and calibrating your desired angle and fixing the busbar in the right place you can start the operation by pressing the foot pedal. To determine the distance of the bend to the edge of busbar, you can use the installed ruler or positioning guide along the fixed rode.

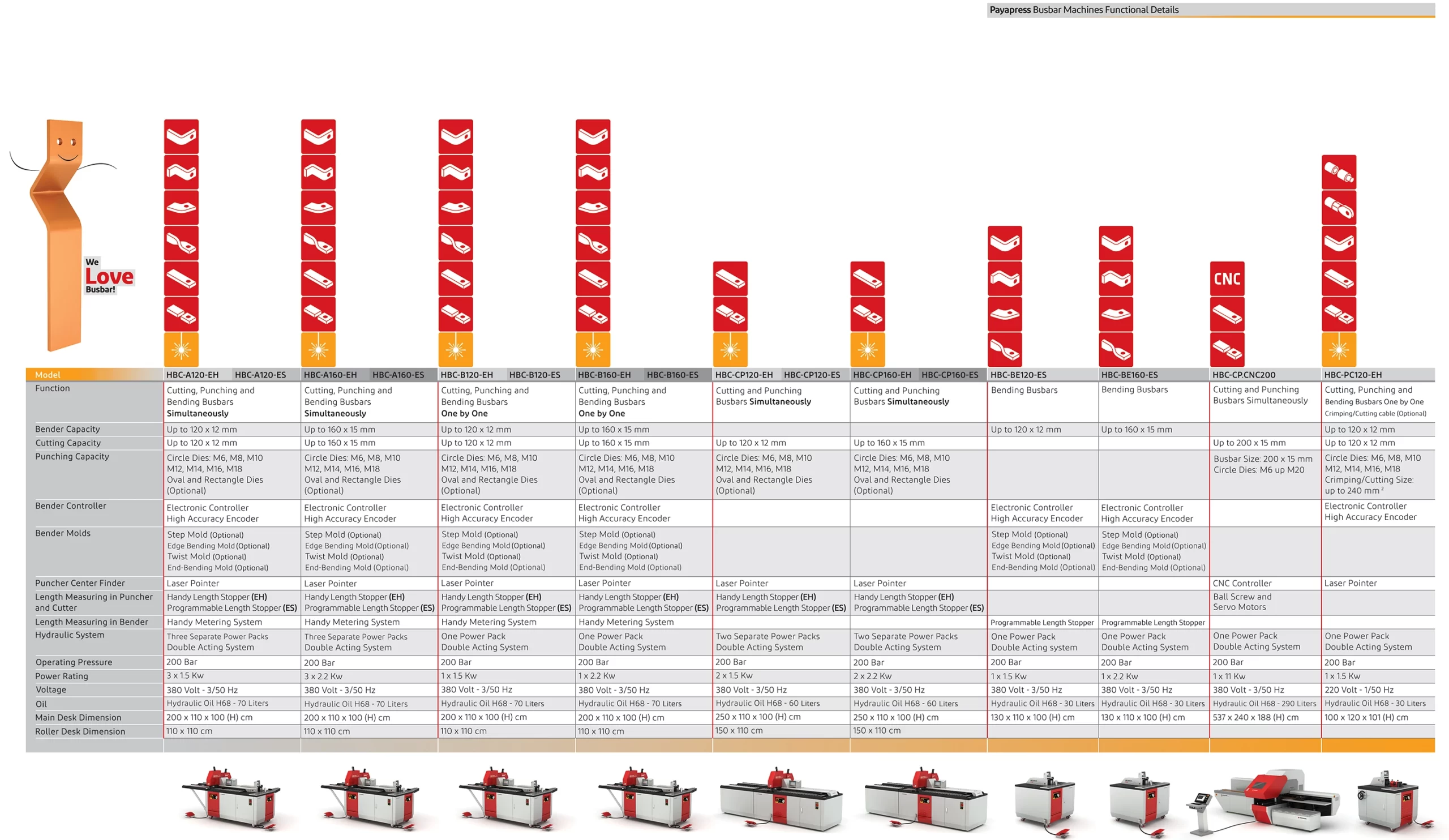

| HBC-BE120 ES | MODEL |

|---|---|

| Bending Busbars | Function |

| Up to 120 x 12 mm | Bender Capacity |

| Electronic Controller High Accuracy Encoder | Bender Controller |

| Step Mold (Optional) Edge Bending Mold (Optional) Twist Mold (Optional) End-Bending Mold (Optional) |

Bender Molds |

| Programmable Length Stopper | Length Measuring in Bender |

| One Power Pack Double Acting System |

Hydraulic System |

| 200 Bar | Operating Pressure |

| 1 x 1.5 Kw | Power Rating |

| 380 Volt – 3/50 Hz | Voltage |

| Hydraulic Oil H68 – 30 Liters | Oil |

| 130 x 110 x 100 (H) cm | Main Desk Dimension |

FIND YOUR SOLUTION

FAQ's

Frequently asked questions

40 to 90 working days depends on the product model and the region of the customer.

The main desk dimension is 130 × 110 × 100 (H) cm

The operating pressure for HBC-BE120 is 250 bar

The power rating of this device is 1 × 1.5 Kw

4 optional molds are available for this device but special molds can be made by the customer’s order.

NEED

CONSULTATION?

Feel free to contact us and

ask your question, its absolutely free.