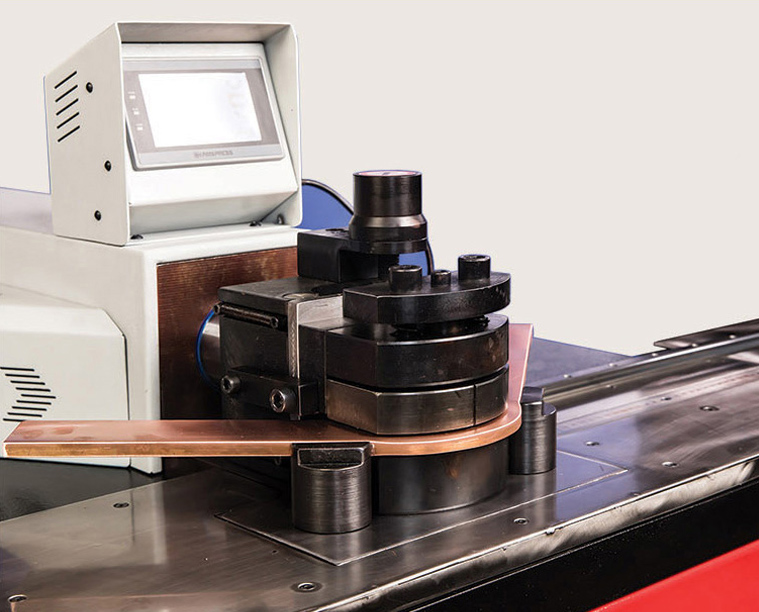

Bender station

To bend copper busbars up to 120*12 mm simultaneously

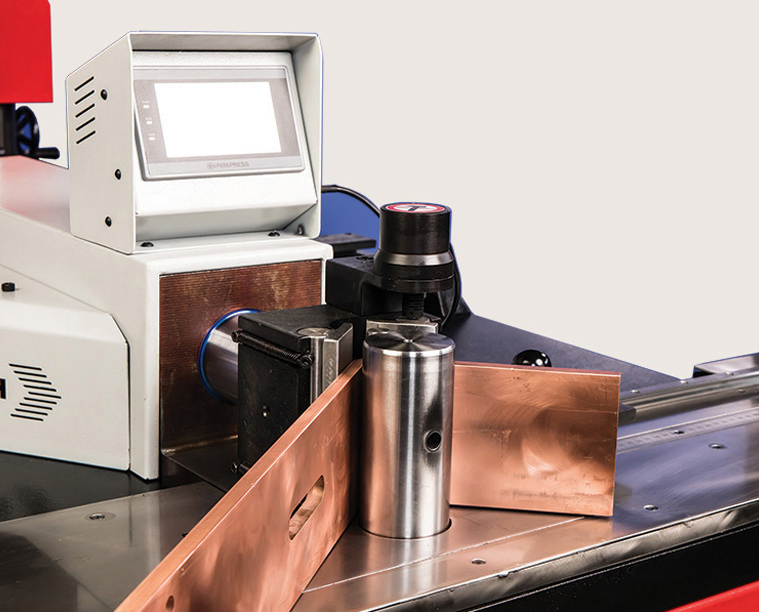

Hydraulic Power Packs

Equipped with 3 power packs

Puncher station

To punch copper busbars up to 120*12 mm simultaneously

Digital controller for puncher and cutter

To give instructions to the puncher and cutter station to reach to perfect results

Digital controller for bender

To give instructions to the bender station to reach to perfect results

Model: HBC-A120 ES/EH

Busbar Bending Machine & Busbar Punching Machine & Busbar Cutting Machine

3 in 1 Busbar Machine

What is 3 in 1 Busbar Machine?

When it comes to busbar machines, HBC-A shines above all. This device is a full functioning 3 in 1 busbar machine that could fulfill all of your needs regarding busbar processing. In all three processes, The maximum busbar size that can be obtained is 12 × 120 mm. To explain more about this device the first thing that should be mentioned is that this device is equipped with 3 power packs which will give you the option to operate on all of the three sections which is punching, cutting and bending. This means 3 operators could work simultaneously on the device without having any disruption. This busbar machine is the most popular device among other devices in our wide range of products and the reason is that it can handle all of the busbar processing levels such as cutting, punching and bending at the same time.

High precision plays a very important role on this device. With the help of programmable length stopper you will be able to get the finest and the most accurate results from each section. Also this device has been recently equipped with industry 4.0 which helps you with getting feedback from device at any time.

INTRODUCTION

TECHNICAL INFORMATION

Busbar Processing Machine Features

Bender

– Bender controller equipped with spring back compensation system.

– Digital angle indicator leads to perfect bending result.

– Rotatable plates prevent fractions in busbar surface

Step mold (Optional)

– To create too closed bends in one stroke

– could be designed in different sizes by order

Edge bending mold (optional)

– To bend busbars from edge side

– Busbar size limit: 40 × 10 mm

Up to 90 degree and 50× 10 mm

Up to 45 degree

Twist bending mold (Optional)

– To twist busbars for special purpose

– Busbar size limits: 60 × 10 mm

Up to 90 degrees.

Puncher

Laser pointer helps to find the center of holes easily

– Easy and changeable dies

– Movable stripper plate prevents fraction in dies

– Double acting hydraulic system prevents sticking dies in busbar after punching

Guides could be moved up to center of dies

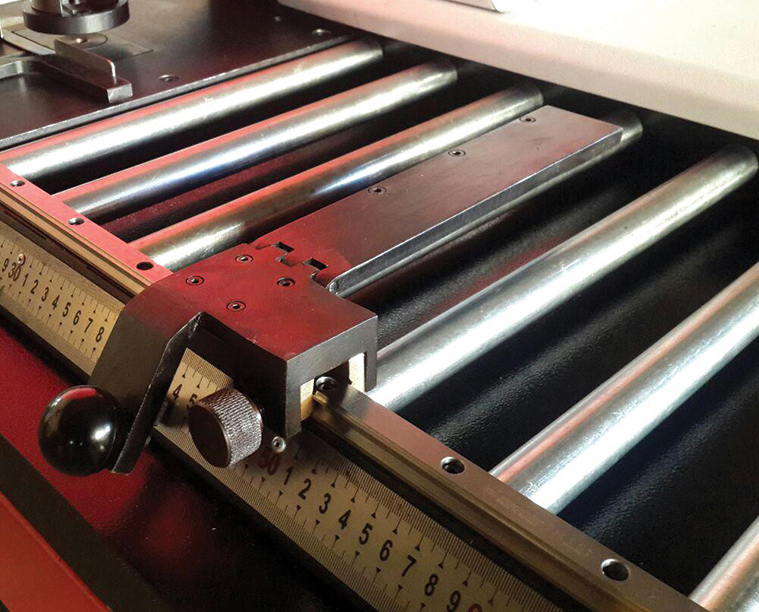

Rollers at two side of puncher for ease of busbar movement

Programmable Length Stopper cause high accuracy in positioning of holes (Optional)

– Could be programmed in absolute and incremental positions

– Programmable for 20 positions

Handy Length stopper with high accuracy adjustment

Circle dies from M6 up to M18

Oval and rectangle dies (Optional)

Cutter

– Precise cutting with high quality

– Perfect finishing after cutting

– Center oriented guide leads to the best result

– Programmable Length Stopper cause high accuracy in positioning of cuts (Optional)

– Could be programmed in absolute and incremental positions

– Programmable for 20 positions

Rollers at two sides of cutter for ease of busbar movement

Handy Length Stopper with high accuracy adjustment

|

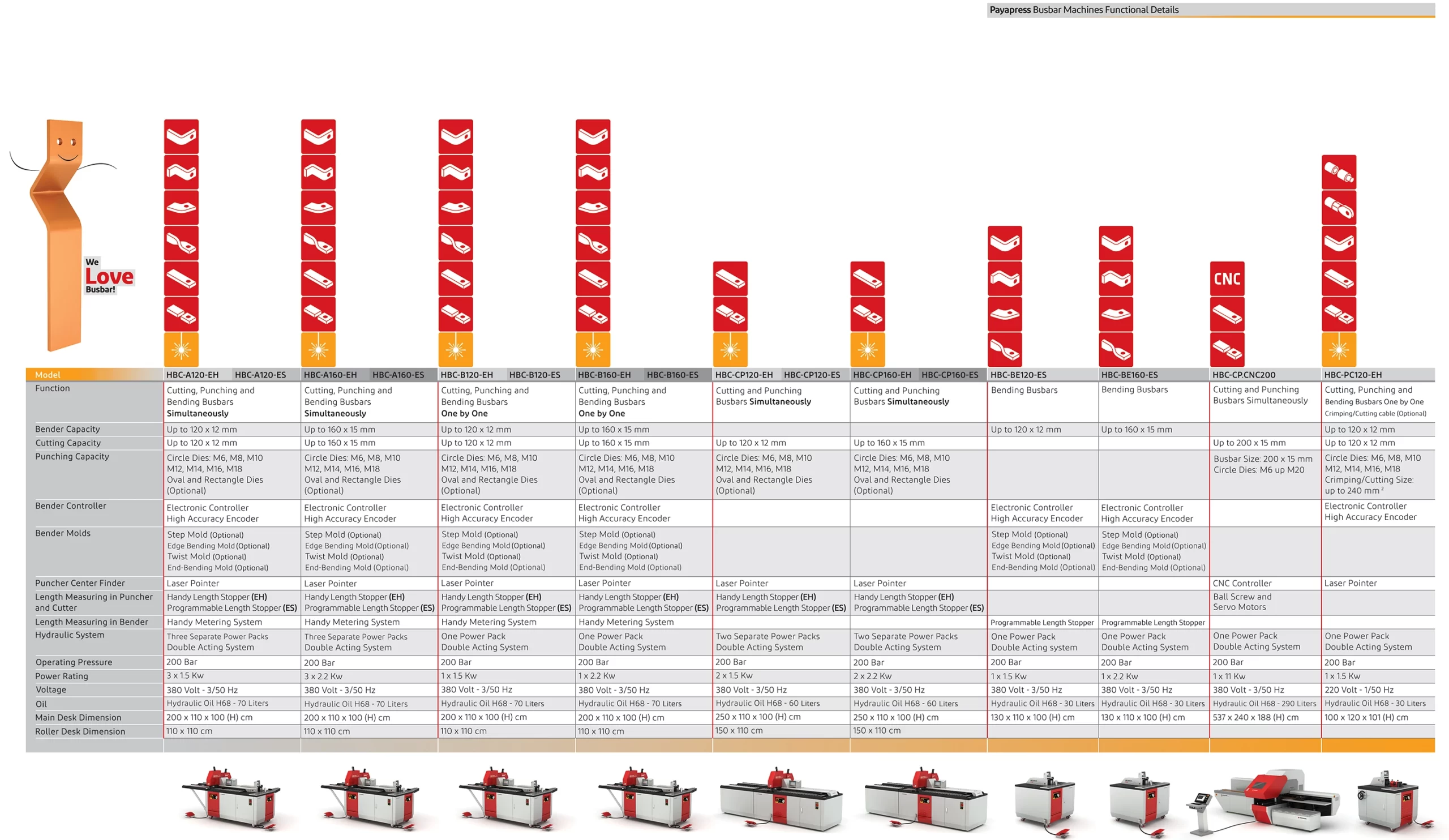

HBC-A120-EH | HBC-A120-ES |

MODEL |

|---|---|

| Cutting ,Punching and Bending Busbars Simultaneously | Function |

| Up to 120 x 12mm | Bender capacity |

| Up to 120 x 12mm | Cutting capacity |

| Circle dies: M6 up to M18 Oval and Rectangle Dies (Optional) | Punching capacity |

| Electronic Controller High Accuracy Encoder |

Bender controller |

| Step Mold (Optional) Edge Bending Mold (Optional) Twist Bending Mold (Optional) End-Bending Mold (Optional) |

Bender Molds |

| Laser Pointer | Puncher center finder |

| Handi Length Stopper (EH) Programmable Length Stopper (ES) |

Length measuring in puncher and cutter |

| Three Separate Power Packs Double Acting System | Hydraulic system |

| 200 Bar | Operating pressure |

| 3 x 1.5 Kw | Power rating |

| 380 volt – 3/50 Hz | Voltage |

| Hydraulic Oil H68 – 70 Liters | Oil |

| 200 x 110 x 100 (H) cm | Main desk dimension |

| 110 x 110 cm | Roller desk dimension |

FIND YOUR SOLUTION

FAQ's

Frequently asked questions

All of the Payapress devices are equipped with “Siemens” motors.

Z-Shape bending die, Edge bending die, Narrow bending die, short leg bend mold which all are optional and can be made by customer’s order.

Circle dies are from M6 up to M18, Oval and rectangular dies are optional and can be made by the customer’s order.

For gaining more information about the price contact the sales department.

Payapress will provide you with bending machines that are equipped with a rotary encoder with a pulse

factor of 3600 pulses per revolution in couple that is directly connected to the movable rotating plates of

the bender.

NEED

CONSULTATION?

Feel free to contact us and

ask your question, its absolutely free.