Control console

To give directions and drawings to the device

Punching and Cutting station

To cut and punch busbars up to 200*15 mm

Main key

To cut off the main power in dangerous times

Emergency stop button

To stop the machine in case of emergency

Model: HBC-CP.CNC200

CNC Punching Machine & CNC Cutting Machine

2 in 1 CNC Machine

What is CNC Busbar Machine?

CNC punching machine always comes first when we are talking about high speed, high precision and high technology. Payapress CNC busbar processing machine is a user-friendly device which gives you the option to cut and punch busbars without interfering the process and make the perfect result. The HBC – CP – CNC200 is a CNC machine designed and programmed for precision drilling and cutting of copper busbars. All products in this CNC Punching/Cutting machine are produced automatically.

How to operate

1-Cut

2- Punch

The busbar must be manually pushed into the machine towards the inlet and on the rollers. At this stage, the clamp takes the location of both sides of the busbar for proper positioning. After the punching operation, the busbar is released and guided out automatically. To continue working on another busbar continuously, the clamp goes backwards by the program given to it and performs the operation on the next busbar. This program is given by the operator to the computer connected to the device. Therefore, the operator needs CNC system programming skills. Scheduled items can be stored in memory as codes and numbers or alphabetically and used for projects. If you are looking forward to Bend busbars as well, you should check out our Busbar Bending Machine that comes with high-tech equipment and multiple bending molds.

INTRODUCTION

TECHNICAL INFORMATION

CNC Busbar Machine Features

Professinal CNC Busbar Machine is designed in order to facilitate punching & cutting Busbars in high speed with high percision.

This Machine is equipped with seven tool stations and could handle busbars in length of 4 meters with thickness of 15 mm.

CNC controller provide wide rang of different size of holes punching in shortest time with high accuracy.

Extreme durability and unrivalled speed characterize the professional production line.

The machine is fully automated once the production process is launched.

The linear tool carrier(y-axis) has 7 stations that hold 6 punching and one cutting tool.

Punches and dies can be changed rapidly.

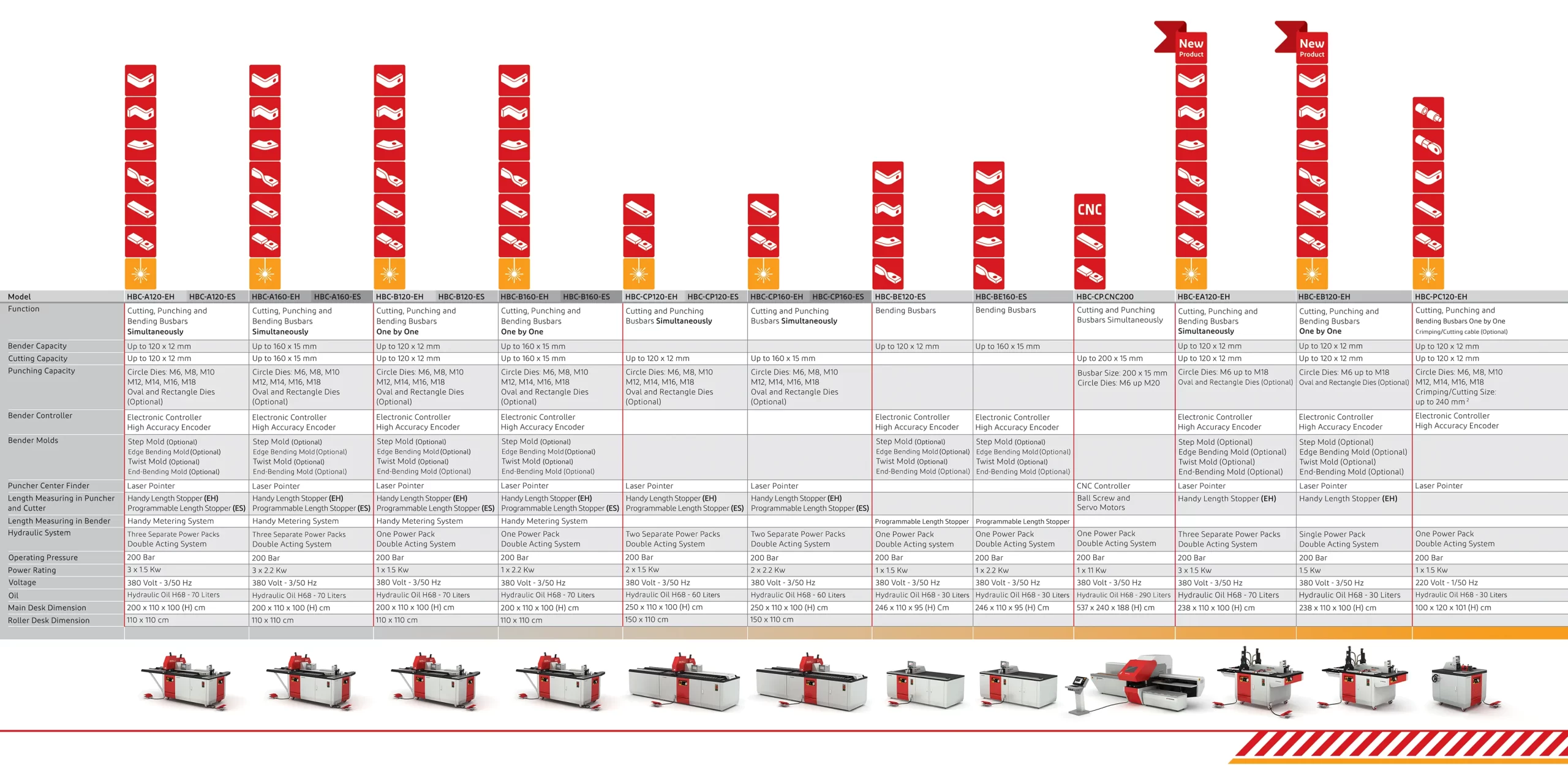

| HBC-CP.CNC200 | MODEL |

|---|---|

| Cutting and punching busbars simultaneously | Function |

| Up to 200 x 15 mm | Cutting capacity |

| Busbar size :200 x 15 mm Circle dies :M6 UP M20 | Punching capacity |

| CNC controller | Puncher center finder |

| Ball Screw and Servo Motors | Length measuring in puncher and cutter |

| One Power Pack, Double Acting System | Hydraulic system |

| 400 (KN) | Max Force |

| 200 Bar | Operating pressure |

| 1 x 11 Kw | Power rating |

| 380 Volt – 3/50 Hz | Voltage |

| Hydraulic oil H68 – 290 liters | Oil |

| 537 x 240 x 188 (H) cm | Main desk dimension |

FIND YOUR SOLUTION

FAQ's

Frequently asked questions

The maximum force of this device is 300 {kn}

Length measuring in both cutter and puncher is done by ball screw and servo motors.

The punching and cutting capacity of this device is up to 200 × 15 mm.

Circle dies sizes are from M6 up to M20.

The operating pressure of this device is 280 Bar

NEED

CONSULTATION?

Feel free to contact us and

ask your question, its absolutely free.