Busbar Axis

Hand-Wheel

To move up and down to change the head

PLC

To give directions and receive feedbacks from the device

Fast tool change

Fast switching dies facilitate work with this machine

Foot pedal

It is used to move the hydraulic arm back-forward and to make operation on automatic mode

Model: HBC-PC120

Busbar Processing Machine

Workshop Busbar Machine

Workshop Busbar Machine

Workshop portable machine is one of our most popular machines and has a wide range of customers. The reason that this device is so popular among others is its small structure and could fit even in small workshops, also with the help of this machine you can do all three operations on your aluminum and copper busbar, which are Punching, cutting, and bending. The workshop busbar processing machine is actually a 3-in-1 busbar machine but with an economical price and it also takes up less space so more people in this business could afford this efficient busbar machine. Having this machine is like having a baby “HBC-A120” and with just one power pack! But what is the difference between this device and HBC-A?! The difference is this device only works with one power pack, which means that you cannot use all of its features at the same time and you have to change the heads to change the process you’re going with. For example, if you’re operating the cutting process on a busbar and now you need to get some punch on it too you will have to change the whole head. But on this device, this process can be done in no time and the head changing process can be done really fast. Another difference you can spot in the working process of this device is that it’s also capable of “Crimping and cutting cables. As mentioned above just by changing heads you can also be capable of doing operations on cables. The crimping cable capacity is up to 300mm² and cutting is up to 240 mm². The busbar bending and cutting capacity on this device is up to 120 × 12 mm. In the punching section, the usual circle dies sizes are from M6 up to M18 (rectangle and oval dies are optional).

INTRODUCTION

TECHNICAL INFORMATION

Workshop Busbar Processing Machine Features

This busbar processing machine is able to fulfill all of your desires according to perform operations on an aluminum or copper busbar also Cables. So this can be a really good choice for people who are dealing with busbars and cables and also for them who has small workshops. The operating pressure of this device is 150 bar, the power rating is 1 × 1.5 Kw and the voltage is 220 Volt – 1/50 Hz.

Double acting system

As you know a hydraulic system uses oil or other fluids to power an actuating cylinder piston which is moved to achieve a specific task. There are two types of hydraulic cylinders:

A) Single-acting hydraulic cylinder

B) Double-acting hydraulic cylinder

In this case, we only pay attention to the “Double-acting system”, and the reason is we only use the double-acting system on all of our devices.

Now, what is a “Double-acting system”?

A double-acting cylinder uses two lines and gives you the full power of your hydraulic system in both directions. If you need to press and lift with the same arm or another device, a double-acting cylinder is ideal. This device has been upgraded recently and has equipped with 4.0 industry technology which can help the devices to get feedback from the process during the operation at any time.

| HBC-PC120-EH | MODEL |

|---|---|

| Cutting, Punching and Bending Busbars One by One Crimping/Cutting Cable (Optional) |

Function |

| Up to 120 x 12 mm | Bender Capacity |

| Up to 120 x 12 mm | Cutting Capacity |

| Circle Dies: M6, M8, M10, M12, M14, M16, M18 Crimping/Cutting Size: up to 240 mm2 |

Punching Capacity |

| Up to 240 mm2 | Crimping Cable Capacity |

| Electronic Controller High Accuracy Encoder |

Bender Controller |

| One Power Pack, Double Acting System | Hydraulic System |

| Laser Pointer | Puncher Laser Finder |

| 200 Bar | Operating Pressure |

| 1 x 1.5 Kw | Power Rating |

| 220 Volt – 1/50 Hz | Voltage |

| Hydraulic Oil H68 – 30 liters | Oil |

| 100 x 120 x 101 (H) cm | Main Desk Dimension |

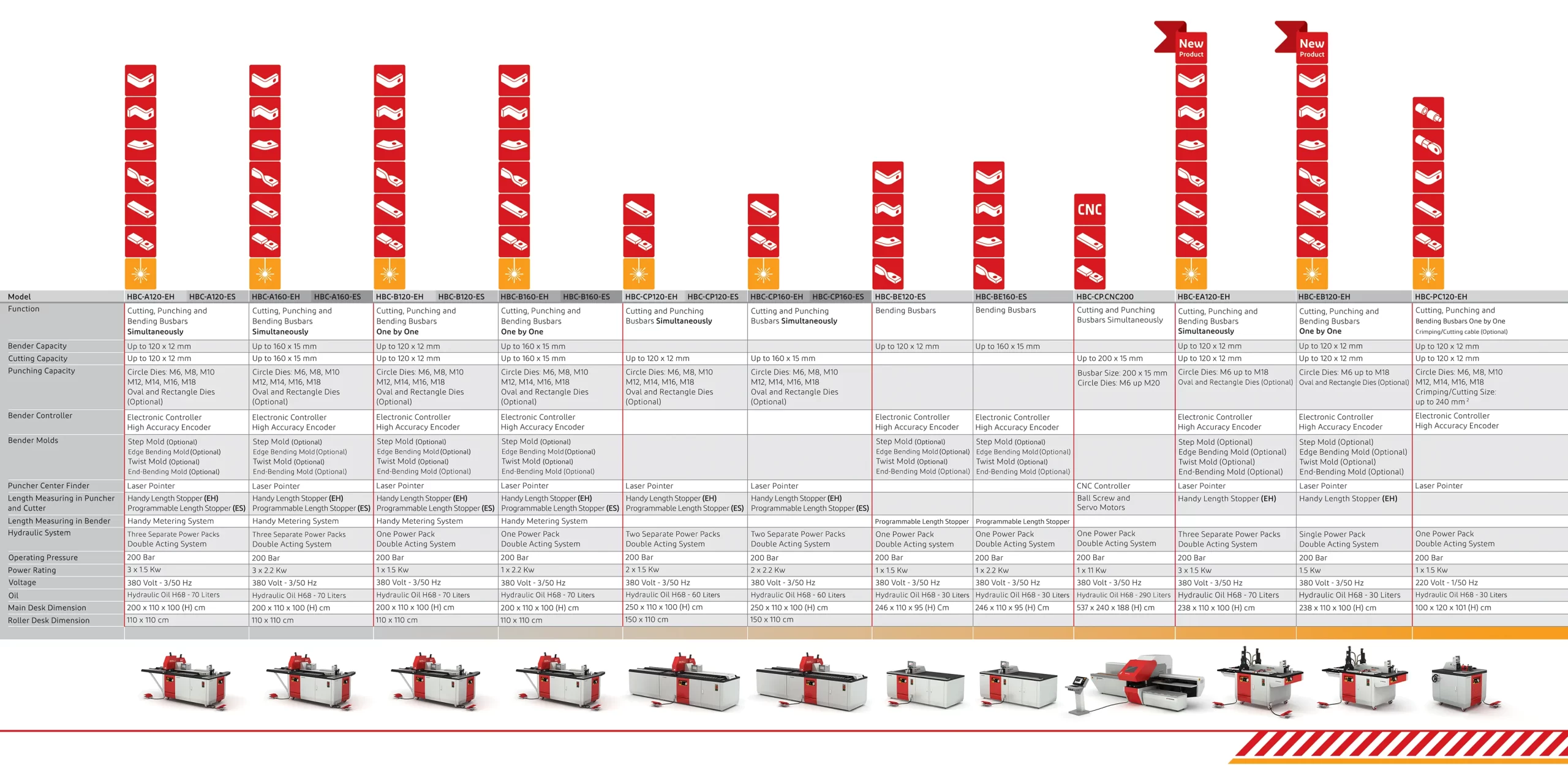

FIND YOUR SOLUTION

FAQ's

Frequently asked questions

The dimension of this device is 100 × 120 × 101 (H) cm

It could crimp cables up to 300mm².

The cable cutting capacity is up to 240 mm².

Circle dies are from M6 up to M18.

The bending capacity is up to 120 × 12 mm.

NEED

CONSULTATION?

Feel free to contact us and

ask your question, its absolutely free.