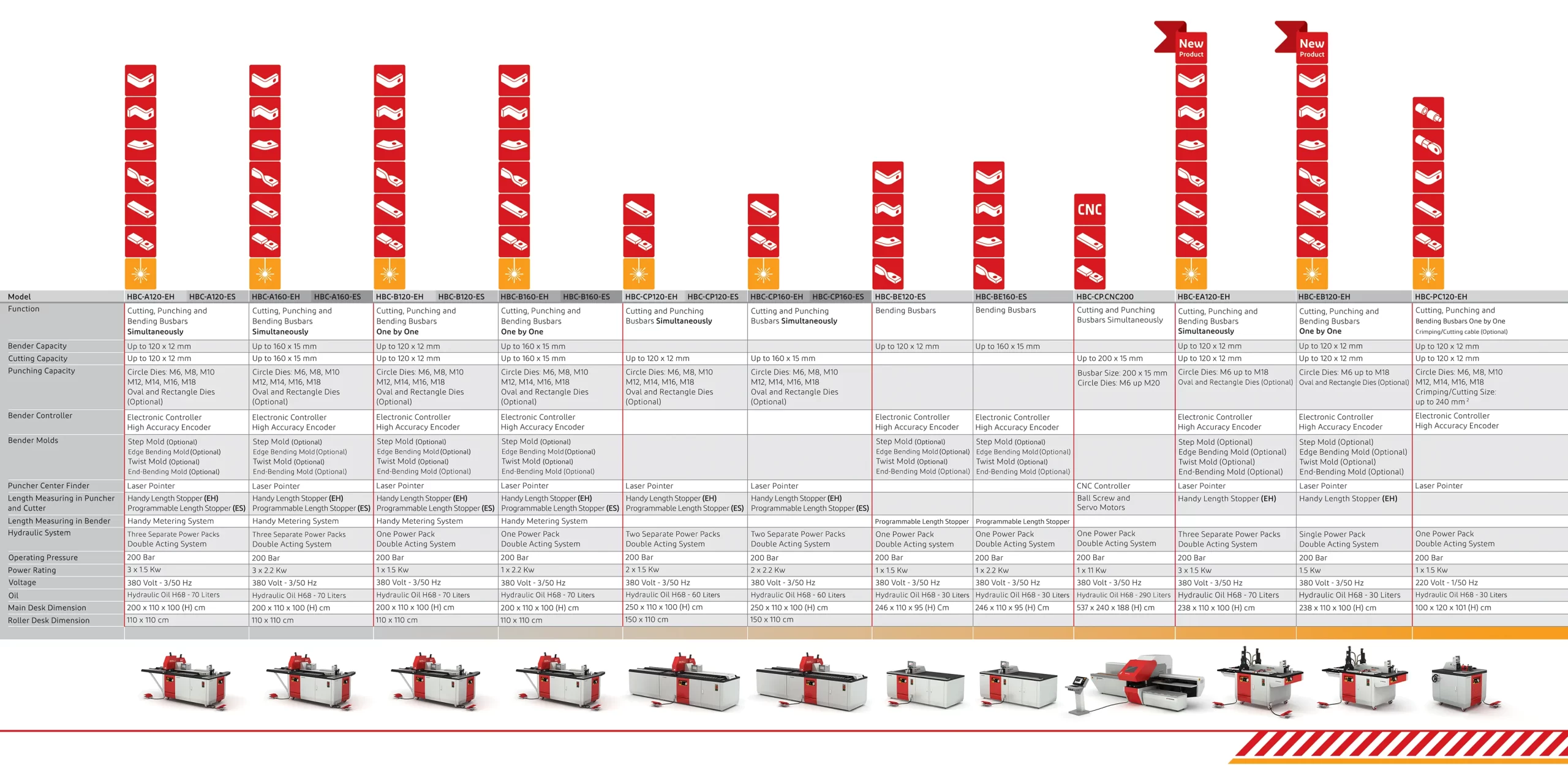

Quick tool change

Easy tool change to get to results faster

Power button

It is used to Turn On/Off the Machine.

Hydraulic power pack

To generate power to the device

Foot Pedal

It is used to move the hydraulic arm back-forward and to make operation on automatic mode

"*" indicates required fields

Model: HBC-BE160 ES/EH

Busbar Bending Machine

Electrical Busbar Bender Machine

Busbar Bender Machine

Busbar bender machine is one of our Busbar machine As you know bending busbars plays a really important role in manufacturing switchgears. First of all, bending busbars for a switchgear will help to reduce the amount of copper usage, also it reduces the costs of creating it. Reducing the electron diffraction and also creating beauty in electrical panels are the other reasons to bend busbars. So as explained bending busbars is a really important job in this industry and that leaves us with the professional busbar bender machine of Payapress company that could help you to bend your aluminum and copper busbars in multiple shapes. This busbar bending machine is capable of bending busbars up to 15×160 mm which is the most used busbar size in this industry. HBC-BE160 has many options to help you get the best bending results with high accuracy in many shapes in a reasonable amount of time that we are going to get to it below. The bender of this device is equipped with two independent systems to achieve bending with high precision and repeatability to repeat bending process in a high number of times.INTRODUCTION

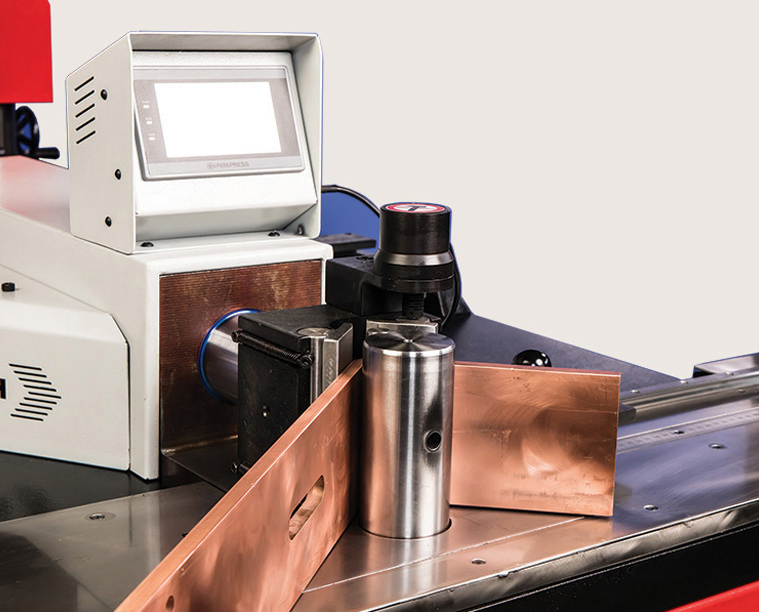

TECHNICAL INFORMATION

Busbar Bender Machine Features

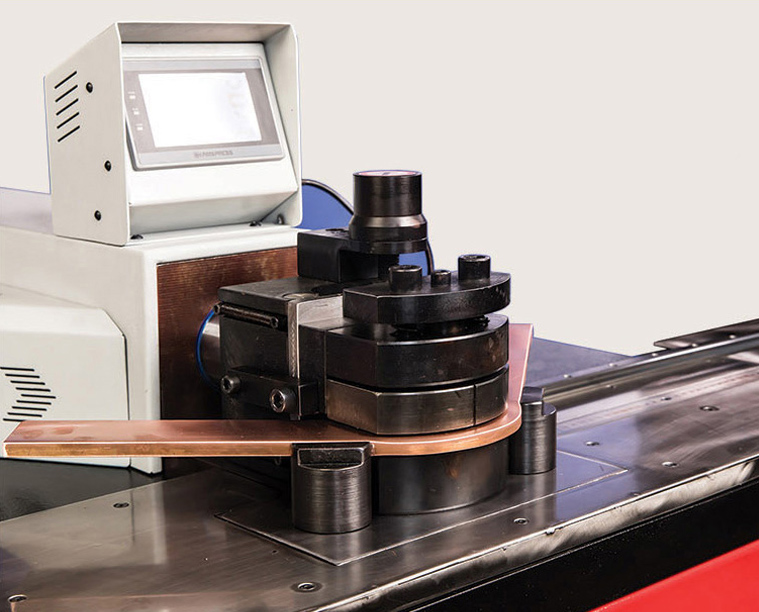

1-Rotary measuring system: Busbar bender machine is one of our Busbar machine, A rotary encoder with a pulse factor of 3600 pulses per revolution in couple is directly connected to the movable rotating plates of the bender. Since these plates are attached to the back of the busbar and rotates with it while bending process, the amount of rotation is directly transferred to the encoder (5 Pulses each degree), Then, the bender controller system is online to adjust the bending amount and after reaching the desired bending angle, it ends the process.2-Linear measuring system: A digital ruler consists of a magnetic strip and a digital receiver attached to the end of the piston rod measures and controls the advance rate of the piston in each bending process. This system provides bend repeatability with an accuracy of 5 microns, which can lead to same size and numerous bends. It is also possible for the operator that instead of entering the angle from the beginning, enter the stroke length on the device screen. It should also be noted that the roller plate installed in the movable jaw section of the bender rotates dynamically during bending along with the busbar, which this design advantage prevents the bottom surface from being stretched. The tire moves forward on other surfaces and creates a line on the underside of the tire during bending. Among the other features of the bending section, it is possible to install a rod with different radii on the fixed jaw of the bender, which makes the bending arc more accurate in different thicknesses.1- Twist bending moldIn some cases, in order to create a connection between the busbar and the desired piece, we face the challenge of the busbar not being aligned with the installation location. And therefore, most of the consumers have to use several busbars to make this connection. The solutions proposed by Payapress company is to use “Twist bending mold” which makes it possible to rotate the direction of the 10 × 60 mm busbar up to 90 degrees, which in necessary cases it is very useful. It is possible to install this complex bend on the busbar machines of Payapress Company.2- Edge bending moldIn some cases, for busbars with different widths and thicknesses, instead of using two busbars perpendicular to each other, we can use the possibility of bending up to 90 degrees on the coppers.3- Z-Shape moldAs you know, in some uses of copper busbars, we are forced to make two bends at a very short distance. In many busbar bending machines, there is generally a 60mm limit for bending due to the use of tools called “bending rollers” in creating close bends. If in the electrical panel design process, we need to make a bend at a shorter distance we should use a mold with higher efficiency, this mold is called “Z-shape mold”.| HBC-BE160 ES | MODEL |

|---|---|

| Bending Busbars | Function |

| Up to 160 x 15 mm | Bender Capacity |

| Electronic Controller High Accuracy Encoder | Bender Controller |

| Step Mold (Optional) Edge Bending Mold (Optional) Twist Mold (Optional) End-Bending Mold (Optional) | Bender Molds |

| Programmable Length Stopper | Length Measuring in Bender |

| One Power Pack Double Acting System | Hydraulic System |

| 200 Bar | Operating Pressure |

| 1 x 2.2 Kw | Power Rating |

| 380 Volt – 3/50 Hz | Voltage |

| Hydraulic Oil H68 – 30 Liters | Oil |

| 130 x 110 x 100 (H) cm | Main Desk Dimension |

FIND YOUR SOLUTION

FAQ's

Frequently asked questions

What is your payment terms?

We are ready to hear your own ways of payment so we could give you the best service possible

Can you add options to the device by order?

We can customize your requested device by order and drawings that you send us.

What is your Min order quantity?

One set. Our customers can be end users, retailers and wholesalers.

Are all the Labels and instructions of the machine in English?

Yes. the labels on the machine and the Manual books are all made in English version.

What is the variety of your devices?

We have the widest range of busbar machine and we can also manufacture other devices for our customers by order.

NEED

CONSULTATION?

Feel free to contact us and

ask your question, its absolutely free.

"*" indicates required fields