Economic Busbar Machine

Home » Economic Busbar Machine

Economic Busbar Machine

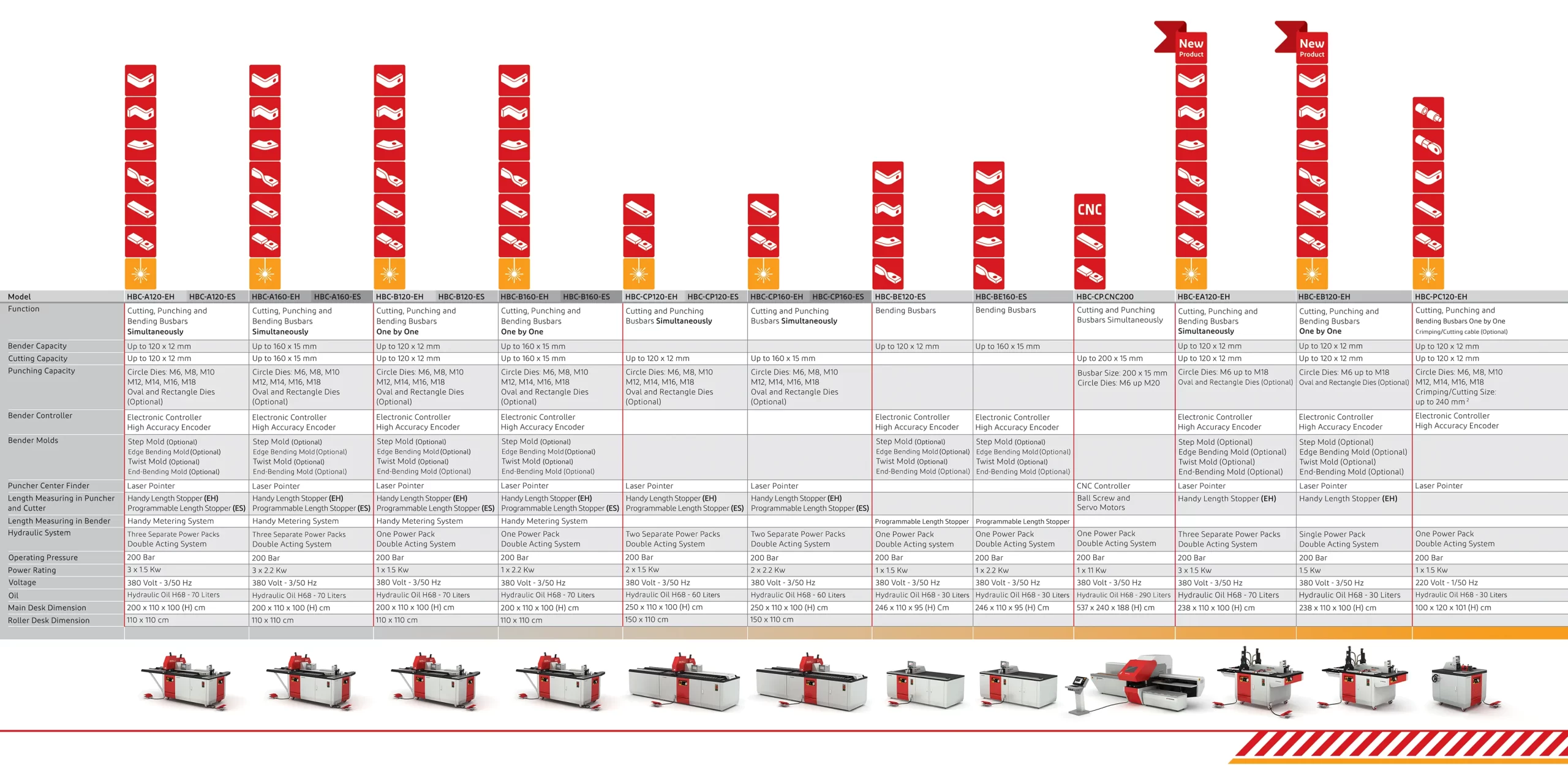

The fabrication of electrical switchgear panels, particularly those exceeding 125 amps, necessitates the use of copper busbars for efficient current conduction. These busbars, optimally designed for minimal resistance, require precise cutting, punching, and bending during panel assembly. The PAYAPRESS E series of busbar processing machines addresses this critical need within switchgear manufacturing workshops. This economical 3-in-1 solution offers both EA and EB models, capable of processing busbars up to 120mm x 12mm. The EA models boast three independent power packs for simultaneous operation across all stations, while the EB models utilize a single power pack. Given the inherent value of copper busbars and the regulatory standards enforced by energy ministries and distribution units, the PAYAPRESS E series prioritizes accuracy in its design and operation, ensuring minimized material waste and compliance with stringent industry requirements.

"*" indicates required fields

Model Series: HBC-E

Affordable Busbar Bending, Cutting and Punching Machine

The PAYAPRESS E series offers economical 3-in-1 busbar processing machines capable of bending, cutting, and punching. This series includes two types: the EA models, equipped with three separate power packs for simultaneous operation at all three stations (bending, cutting, and punching), and the EB models, which utilize a single power pack to drive all three stations. Both the EA and EB series can process busbars up to 120mm x 12mm. If you intrest to any type of busbar bending machine just click

NEED

CONSULTATION?

Feel free to contact us and

ask your question, its absolutely free.

"*" indicates required fields