Busbar Processing Machine

In making electrical panels to conduct electrical current, when the panel ampere is higher than 125 amps, we use copper busbars instead of cables.Busbar is a profile whose cross-section area is optimally designed in such a way as to create the least amount of resistance during the current transfer process. Busbar processing in electrical switchgear create a need for cutting, punching and bending of copper busbar in workshop of switchgear manufacturer company. Due to the sensitivity of the busbar processing (high price of copper busbars – strictness of the Ministry of Energy and distribution units) accuracy in the operation of these machines is a priority in the design and production of this product.

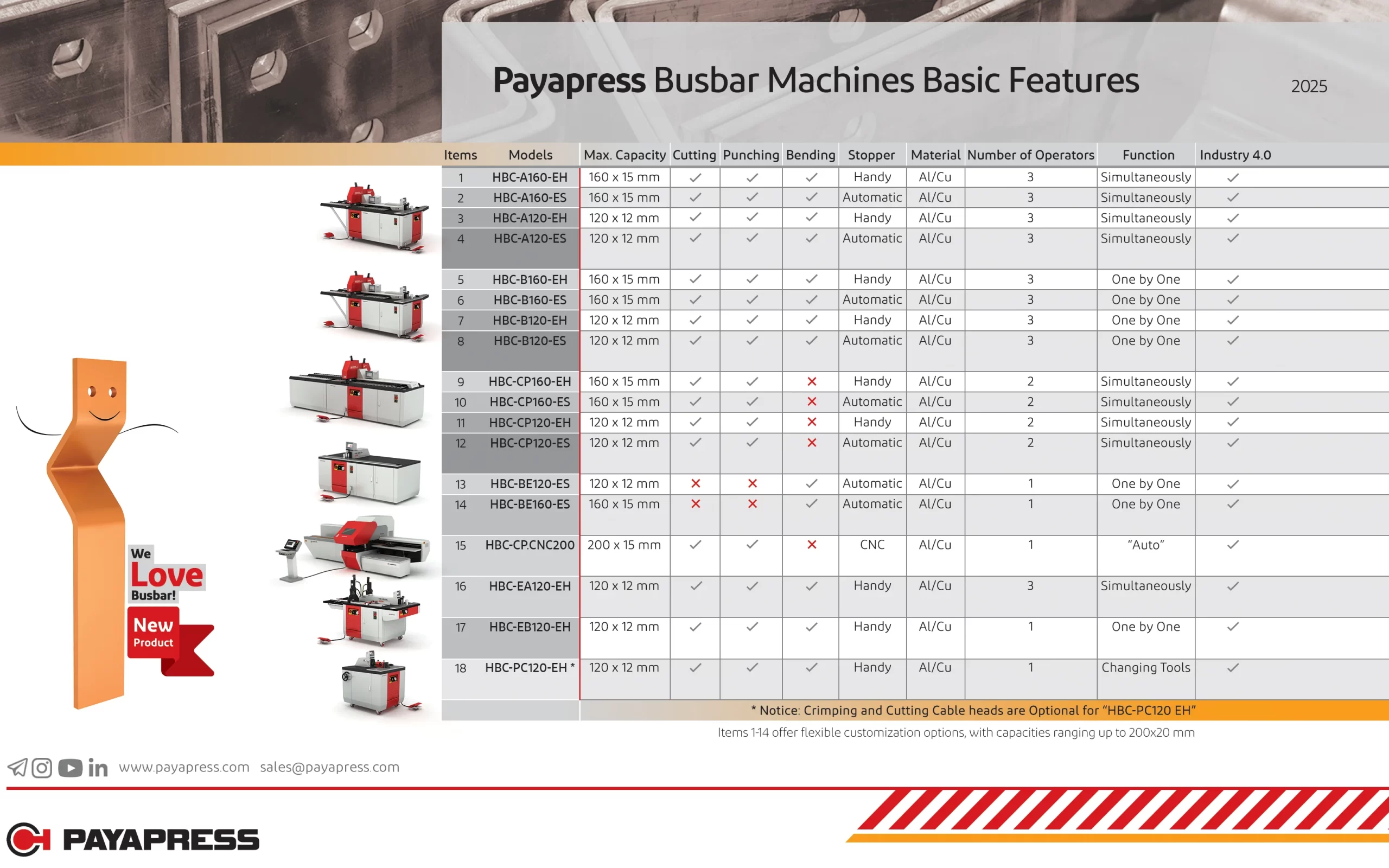

Model Series: HBC-A

Bending ,Cutting and Punching Machine

This series of Busbar machines are 3 in 1 machines, which means busbars could be fully processed (Bending, Cutting, Punching) on these devices. The most Important feature of this series of PAYAPRESS busbar machines is that 3 operators can work on all three stations simultaneously without interrupting the other one and the reason is that this series of machines are equipped with 3 power packs. The difference between Model: HBC-A120 and HBC-A160 is just the maximum size of busbar that can be processed, A120 is capable of process busbars up to 120*12 mm while the A160 can do more and the maximum busbar size is up to 160*15 mm.

Model Series: HBC-B

Bending ,Cutting and Punching Machine

HBC-B series machines are exactly like the A series but with only one difference, The only difference of B series busbar machines is that the operator is able to work on each station at a time and the reason for it is that these machines are equipped with only one power pack which allows you to work on each station at different times. HBC-B series is actually a alternative version of HBC-A series with only a lesser difference and more economical prices for Industries with less financial power.

Model Series: HBC-BE

Busbar Bending Machine

Busbar bending machines are one of the most used devices in the industry. PAYAPRESS company provides its customers with two busbar bending machines that could bend busbars up to 120*12 mm and 160*15 mm. As you know busbars should be bent in different shapes to be installed on the Electrical panels and switchgears for variant reasons. These machines includes different types of bending molds such as; Z-shape mold, Twist bending mold, Edge-Bending mold and etc. to fulfill all busbar bending needs.

Model Series: HBC-CP

Busbar Cutting and Punching Machine

As well as other series, CP series also have two models that could cut and punch busbars up to 120*12 mm and 160*15 mm. These devices are equipped with Two power packs which allows operators to work on each station separately at the same time to speed up the busbar punching and cutting processes. The cutter and puncher with the help of “Programmable Length Stopper” are very precise in positioning of holes and cuts. The Programmable Length Stopper is programmable for 20 positions.

NEED

CONSULTATION?

Feel free to contact us and

ask your question, its absolutely free.