OBTENER PRESUPUESTO GRATUITO

"*" señala los campos obligatorios

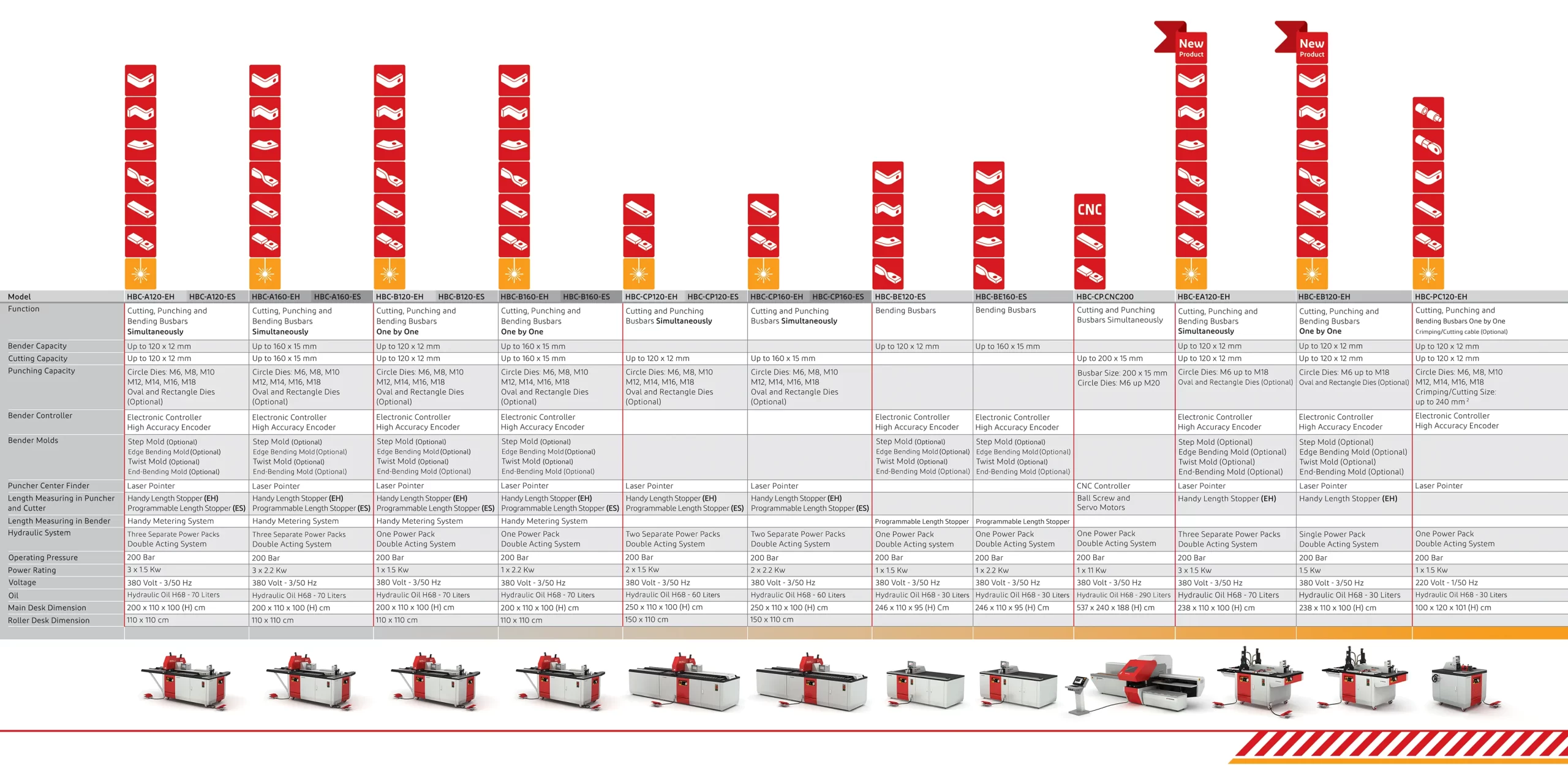

Modelo: CFCM-30ES-30EH

Máquina de conformado de esquinas

Máquina de conformado de esquinas por formado en frío

Máquina de conformado de esquinas

Modelo: CFCM-30ES / CFCM-30EH

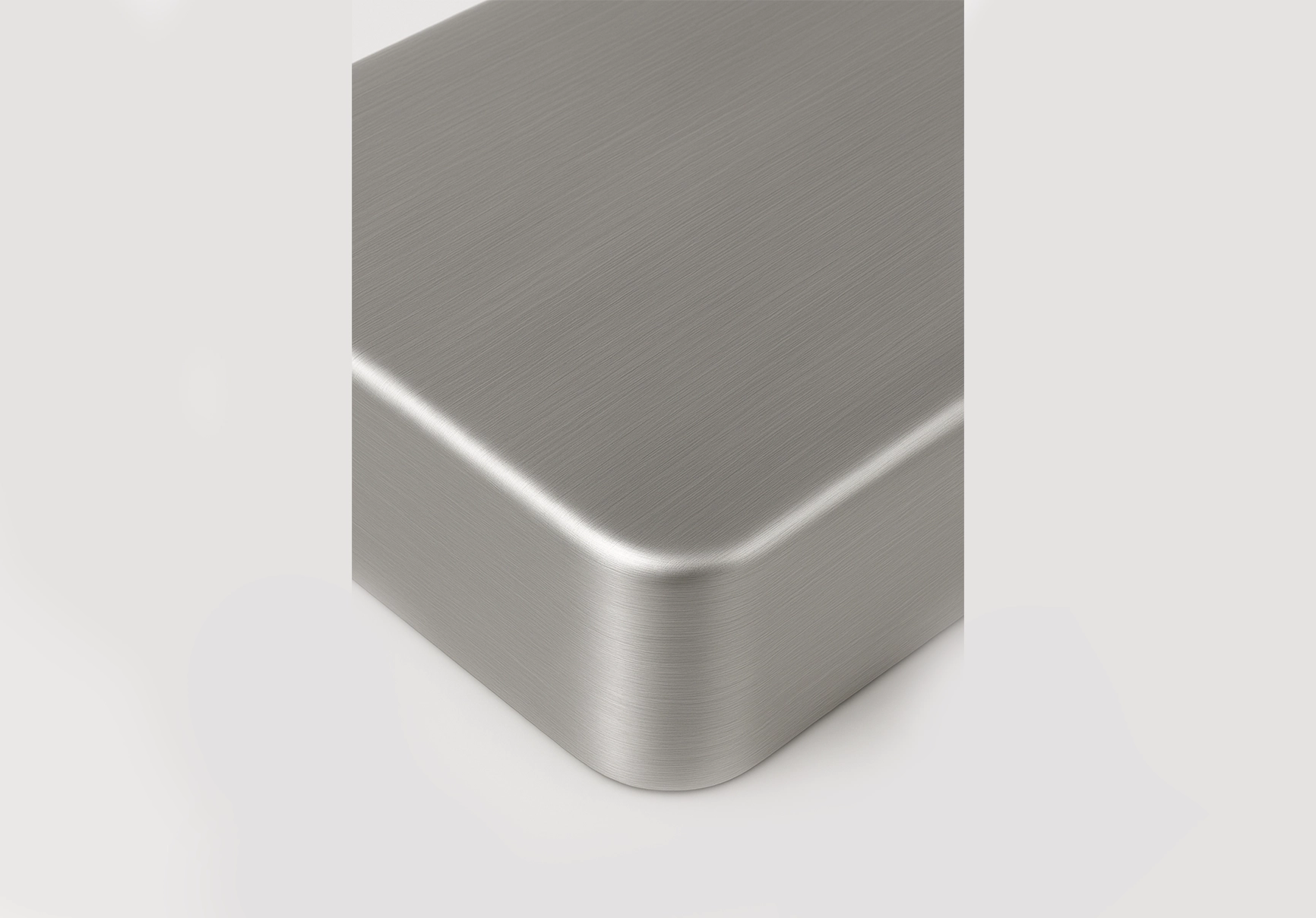

La Máquina de Conformado de Esquinas es una solución sin soldadura para producir esquinas de chapa metálica sin uniones y perfectamente uniformes. Utilizando un preciso proceso de conformado en frío, esta máquina elimina la soldadura, el desbaste y el pulido, reduciendo drásticamente el tiempo de producción y los costos de fabricación.

Diseñada para una alta repetibilidad y un uso industrial a largo plazo, garantiza una geometría de esquina idéntica con una resistencia superior y un acabado limpio, lo que la convierte en una opción ideal para las líneas modernas de fabricación de chapa metálica.

INTRODUCCIÓN

INFORMACIÓN TÉCNICA

Máquina de Conformado de Esquinas: Revolucionando la producción de esquinas en chapa metálica

En el mundo de la fabricación de chapa metálica, lograr esquinas metálicas precisas y uniformes es una tarea crítica. Los métodos tradicionales implican un proceso intensivo en mano de obra y de múltiples etapas que incluye corte, doblado, soldadura, desbaste y pulido. Este proceso extenso no solo consume mucho tiempo, sino que también resulta costoso. La Máquina de Conformado de Esquinas PAYAPRESS (CFCM-30ES / CFCM-30EH) transforma la forma en que se forman las esquinas metálicas al eliminar la necesidad de soldadura y pulido, reduciendo drásticamente tanto el tiempo de producción como los costos, al tiempo que garantiza resultados consistentes y de alta calidad.Características clave de la Máquina de Conformado de Esquinas

- Ingeniería de precisión: La serie CFCM utiliza tecnología avanzada de conformado para proporcionar esquinas sin uniones y estéticamente superiores con alta repetibilidad.

- Versatilidad: Capaz de trabajar con diferentes espesores de chapa metálica y producir doblados con distintos radios, lo que la hace adecuada para una amplia gama de aplicaciones.

- Durabilidad: Fabricada con materiales de alta resistencia y un diseño industrial moderno, garantizando un funcionamiento continuo durante muchos años.

- Fácil operación: Disponible en modelos manuales y automáticos para diferentes espesores de chapa, proporcionando flexibilidad y facilidad de uso al operador.

Beneficios de usar la Máquina de Conformado de Esquinas

La Máquina de Conformado de Esquinas PAYAPRESS incrementa significativamente la velocidad de producción al eliminar la necesidad de soldadura, desbaste y pulido. Garantiza un alto nivel de consistencia en la calidad del producto, ya que cada esquina se forma con precisión. Esto conduce a una reducción de los costos laborales y a un mínimo desperdicio de material, ya que no se requiere intervención manual en los procesos de soldadura y pulido. La flexibilidad de la máquina permite realizar doblados personalizados y diseñar moldes especiales para satisfacer una amplia variedad de necesidades de los clientes.Eficiencia al máximo nivel

Una de las características más destacadas de este equipo es su capacidad para producir esquinas de alta calidad en una fracción del tiempo en comparación con los métodos tradicionales. Gracias a su preciso proceso de conformado y a la posibilidad de cambiar rápidamente los moldes, los usuarios pueden lograr resultados consistentes sin el riesgo de errores humanos. Ya sea que se produzcan doblados en forma de Z o moldes personalizados, esta máquina garantiza alta precisión y eficiencia.Moldes personalizables para diversas aplicaciones

Nuestra Máquina de Conformado de Esquinas cuenta con múltiples opciones de moldes que pueden personalizarse según las necesidades específicas de su proyecto. Entre los moldes más populares se incluyen:- Molde en forma de Z: Diseñado para crear doblados precisos en forma de Z comúnmente utilizados en la industria.

- Molde de doblado de borde: Ideal para formar los bordes de la chapa metálica, proporcionando flexibilidad en forma y tamaño.

- Molde de torsión: Perfecto para crear formas torsionadas de barras conductoras en aplicaciones especializadas.

Especificaciones técnicas

Conclusión

La Máquina de Conformado de Esquinas PAYAPRESS representa una solución innovadora en la industria del conformado de chapa metálica. Elimina etapas costosas y que requieren mucho tiempo, como la soldadura, el desbaste y el pulido, proporcionando a los fabricantes una forma más rápida y eficiente de producir esquinas metálicas de alta calidad y consistencia. Gracias a sus moldes personalizables y a su alta precisión de conformado, este equipo ofrece una flexibilidad inigualable y se convierte en una inversión valiosa para cualquier taller de fabricación.| Modelo | CFCM-30EH | CFCM-30ES |

|---|---|---|

| Sistema para cambiar los ajustes de la máquina según diferentes espesores de chapa | Manual | Automático |

| Dimensiones generales | 1420 × 1200 × 1850 mm | 1420 × 1200 × 1850 mm |

| Rango de espesor | 0.5 a 2 mm | 0.5 a 2 mm |

| Espesor permitido (aceitado) – ST12 | 0.8 a 2 mm | 0.8 a 2 mm |

| Espesor permitido (negro) – ST37 | 1.5 a 2 mm | 1.5 a 2 mm |

| Espesor permitido – acero inoxidable | 0.8 a 2 mm | 0.8 a 2 mm |

| Rango de radio de conformado | 6 a 30 mm | 6 a 30 mm |

| Tamaño mínimo de la pieza | 210 × 210 mm | 210 × 210 mm |

| Peso del equipo principal | 1200 kg | 1200 kg |

| Potencia total | 4.5 kW | 4.5 kW |

| Presión hidráulica máxima | 200 bar | 200 bar |

| Potencia total del motor | Electrogen 1 × 4 kW | Electrogen 1 × 4 kW |

| Tamaño de la HMI | 7 pulgadas | 7 pulgadas |

| PLC | Delta | Delta |

| Capacidad del tanque hidráulico | 50 litros | 50 litros |

| Conexión de tuberías | RN | RN |

| Sellado | Kastas | Kastas |

| Válvula hidráulica | Tork Hydraulics | Duplomatic |

| Bomba hidráulica | Arafan | Arafan |

| Sensor | Autonics | Autonics |

| Códigos de control | Raad | Autonics |

| Contactor AC | Hyundai | Schneider |

ENCUENTRE SU SOLUCIÓN

PREGUNTAS FRECUENTES

Preguntas frecuentes

¿Qué es una máquina de conformado de esquinas?

Una máquina de conformado de esquinas es una herramienta especializada utilizada para dar forma a las esquinas de chapa metálica sin necesidad de soldadura, desbaste ni pulido. Proporciona esquinas sin uniones y de alta calidad con precisión y velocidad, lo que la hace ideal para barras conductoras y otros procesos de fabricación de chapa metálica.

¿Cuáles son los beneficios de utilizar una máquina de conformado de esquinas?

Los principales beneficios de utilizar una máquina de conformado de esquinas incluyen mayores velocidades de producción, reducción de los costos laborales y una disminución significativa del desperdicio de material. Además, la máquina garantiza resultados consistentes y uniformes, mejorando la calidad general de las esquinas metálicas producidas en operaciones de gran volumen.

¿Puede la máquina de conformado de esquinas trabajar con diferentes espesores de chapa metálica?

Sí, la máquina de conformado de esquinas puede trabajar con diferentes espesores de chapa metálica, desde 0,5 mm hasta 2 mm, según el modelo (CFCM-30EH con ajustes manuales y CFCM-30ES con ajustes automáticos). Esta versatilidad permite procesar de manera eficiente una amplia gama de materiales.

¿Es posible personalizar la máquina de conformado de esquinas para diferentes formas y radios?

Sí, la máquina de conformado de esquinas incluye moldes personalizables que permiten producir una variedad de formas de esquinas, como moldes en forma de Z, doblado de bordes y torsión. Esta flexibilidad garantiza que se puedan satisfacer los requisitos específicos de los clientes y fabricar esquinas metálicas altamente personalizadas.

¿Cuál es la vida útil esperada de una máquina de conformado de esquinas?

Gracias a su diseño industrial robusto, el uso de materiales de alta resistencia y su bajo mantenimiento, la máquina de conformado de esquinas está diseñada para durar muchos años de uso continuo. Está fabricada para soportar condiciones de operación exigentes, proporcionando fiabilidad y durabilidad a largo plazo.

¿NECESITA

ASESORÍA?

No dude en contactarnos y

hacer su pregunta, es totalmente gratis.

"*" señala los campos obligatorios