Handy lock in Y axis

To make series holes in a line

Digital indicator guides

To adjust the steel in X & Y directions

Fast switching dies

Fast switching dies facilitate work with this machine

Emergency stop button

To stop the machine in case of emergency

Get a Free Quote

"*" indicates required fields

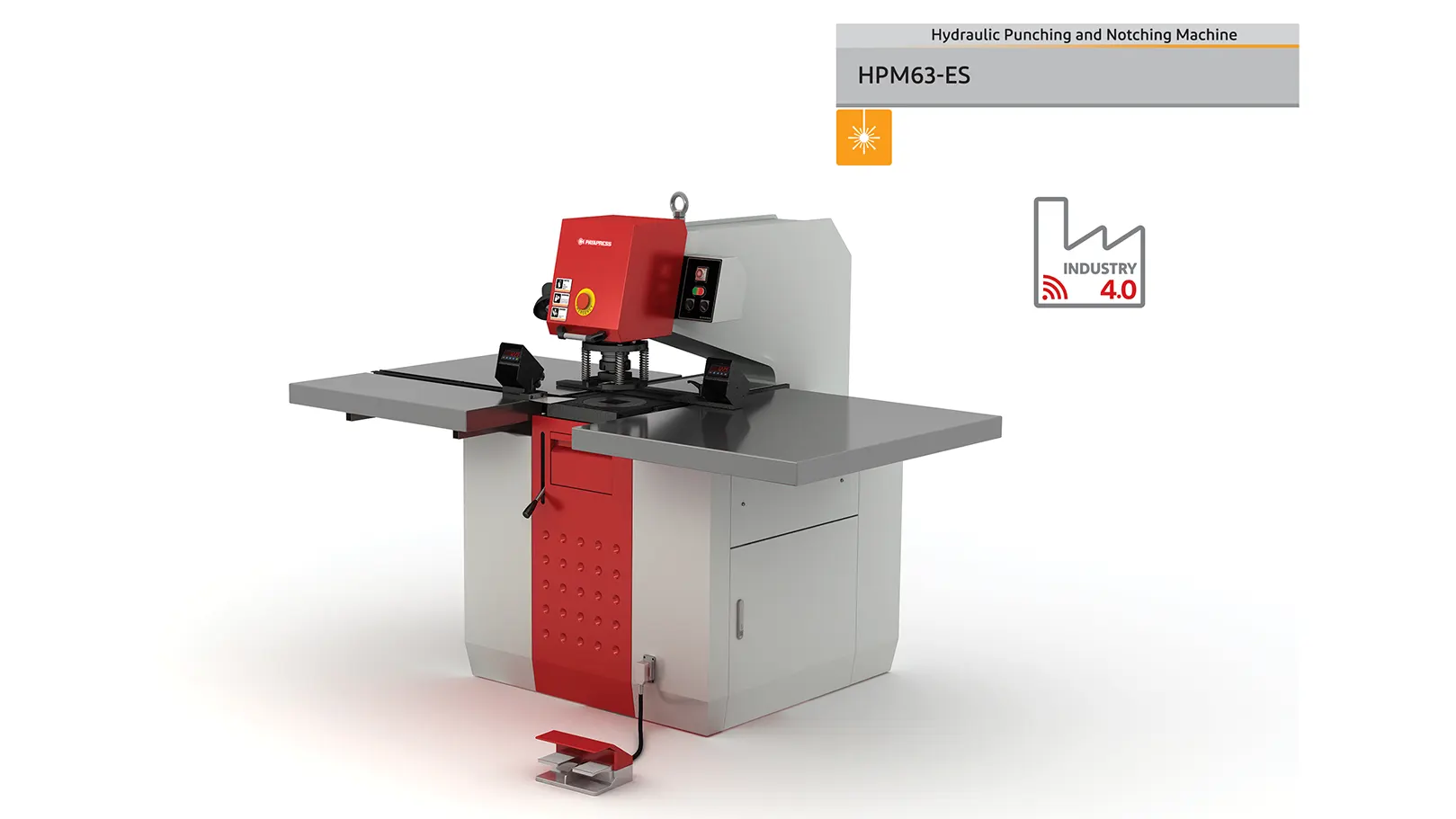

Model: HPM-63S

Sheet Metal Punching Machine

Sheet Metal Punch & Notching Machine

INTRODUCTION

TECHNICAL INFORMATION

Sheet Metal Punch & Notching Machine Features

The adjustments on this device is really user-friendly which includes “digital ruler indicator” for X and Y axis which is optional and “handy lock” in Y axis to make series holes in a line. The HOME point of the device is the reference point of the X and Y axes of the device, which for the X axis is at the end of the right side of the axis and the Y axis is the end of the axis, which is limited by the induction sensor.

To learn more about the notching process and its features, additional information is available that can help clarify the details of this process.

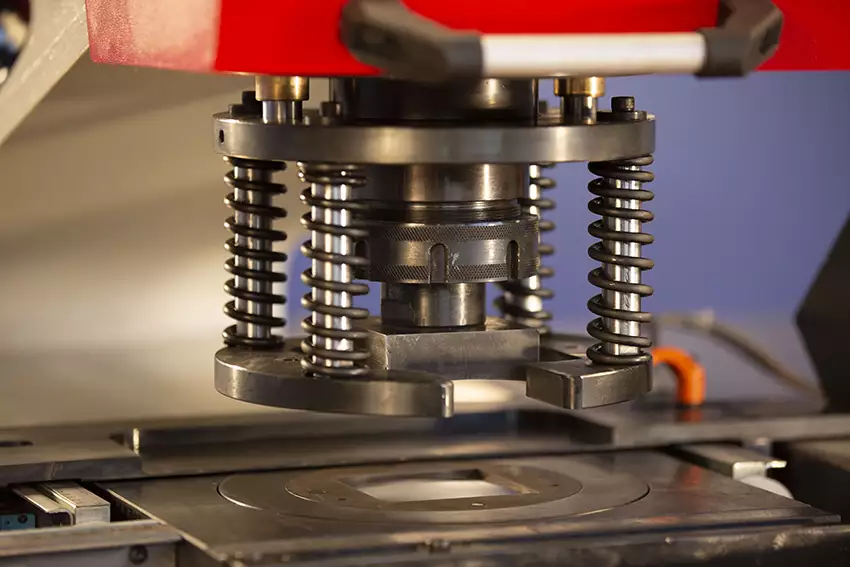

Punches and Dies

As mentioned above this machine has a wide range of dies that could help many industries with their work. These dies are; Round dies, square dies, rectangular dies, louvre dies and etc. Payapress is also ready to provide its customers with special dies that can be made by order. In the past, the workshop punch mold was cast in one place and this caused a very high price for the consumers. But now, we have divided the male and female die package into different parts and when a part starts to get dull we could only change that part.

A) Male die

B) Female die

C) Male Die connector

D) Female Die connector

E) Big Nut

Round molds

This machine is capable of punching sheet metals up to 34 mm. These dies can be used to create; Signal Lamp punch, all kinds of screws in different sizes from M4 and upper sizes and could be used instead of glands as well.

7×7, 9×9 and 15×15 foursquare

One of the most used dies in recent years are small dies that are used instead of screws and clamps. There is the possibility of making these dies with the desired and requested size by customer’s order.

22×22 foursquare

In the past, this mold was used a lot in the switchgear industry, but now it is less used in the industry and it will be send to you according to your device capacity.

Miniature fuse molds

These molds are the most used types of molds in the field of industrial switchboards. It should be noted that sometimes these molds are considered a little bigger so that the miniature fuse can be accurately placed after the color.

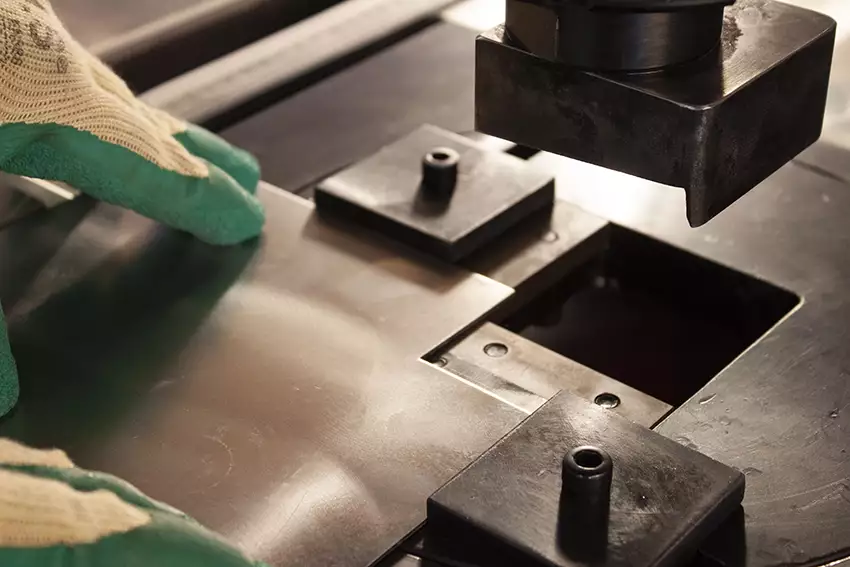

Using a square mold for cutting

Sometimes some users, use sheet metal punch machine instead of a guillotine to reduce production costs. In this case, the following mold is suggested, which can make parallel cuts on the surface of the sheet in one line. Obviously, the dimensions can be changed, but due to the lack of width in this case, if we want to take the width less than the image below, the male die will cause fragility.

92×92 Punch (Ammeter):

The most used mold ordered in Payapress Industrial Company is the ammeter mold, this mold is one of the most used and most important among others.

Counterbored mold

Among the widely used molds in the switchgear industries are the coumterbored molds. These molds can create a protrusion on the surface of the sheet, They are very important in situations where the joint of the board is supposed to be far from the ground or the wall, or to connect two Panels are used interchangeably.

Variety of locks

Siemens lock: The most conventional lock that is generally used in the switchboard industry is the Siemens lock, but it is obvious that using a variety of locks in your product introduction basket can create good added value for switchboard manufacturers.

Briefcase lock

Which were conventionally used in briefcases in the past. Some of these locks have keys, like the general locks, and they are produced with different materials. These types of locks are in addition to the electrical panels is used in firefighting panels and ATM boxes as well.

Mito lock

Recently, this lock has been widely used due to the beautiful appearance it gives to the panel.

Vent molds

The use of these molds is quite clear and it creates ventilation in electrical panels. In this regard, different modes are suggested, and we will examine three examples of these ventilators below.

Two-row ventilator

This mold creates two ventilation slots in each stroke. The mechanism of this mold is in such a way that in order to create air vents in a long series, the air vent mold is placed on the sheet and all the air vents are placed in a line with the positions embedded on the surface of the male die. The standard distance is shown in the map below, but it is possible to customize the sizes you want.

Three-row ventilator

This type of ventilator has a lower quality from a practical point of view to create ventilation, but due to its good appearance, it is used in some LV and MV panels.

Corner cutter molds

One of the most important possibilities of the punching machine is cornering. Due to the high price of the machines that do the cornering work alone, this possibility can be easily implemented on the punching machine by reducing the production costs.

Three conventional examples of cornering are used in the switchgear industry, which will be described separately below:

Simple Corner cutter

The most common use of this simple cornering mold is to make a simple cut.

With the help of this mold, you can create the desired dimensions of your cornering on the surface of the sheet by changing the positions on the female die’s surface in the X and Y axis. In the normal case, this possibility can be done up to 50 mm. If the consumer needs a mold with cornering up to 80 cm, we can also design and manufacture it by order.

Two-bend cornering mold

This mold is used to make two bends in two directions.

Special cornering mold

If you request a template different from the templates described in the cornering section above, you can order the types of templates that are used in your industry.

| HPM-63S | MODEL |

|---|---|

| Punching and Notching | Function |

| 16 ton | Punching power |

| 277*90 | Table dimension |

| 63 cm | Throat depth |

| 133-130*110 | Max. Dies dimension |

| Double acting System | Hydraulic system |

| 3PH/3KW/1400 rpm | Engine |

| 150 bar | Operating pressure |

| 1 x 3 Kw | Power rating |

| 380 V/50 HZ/ 10A | Electric |

| Approx. 900 kg | Total weight |

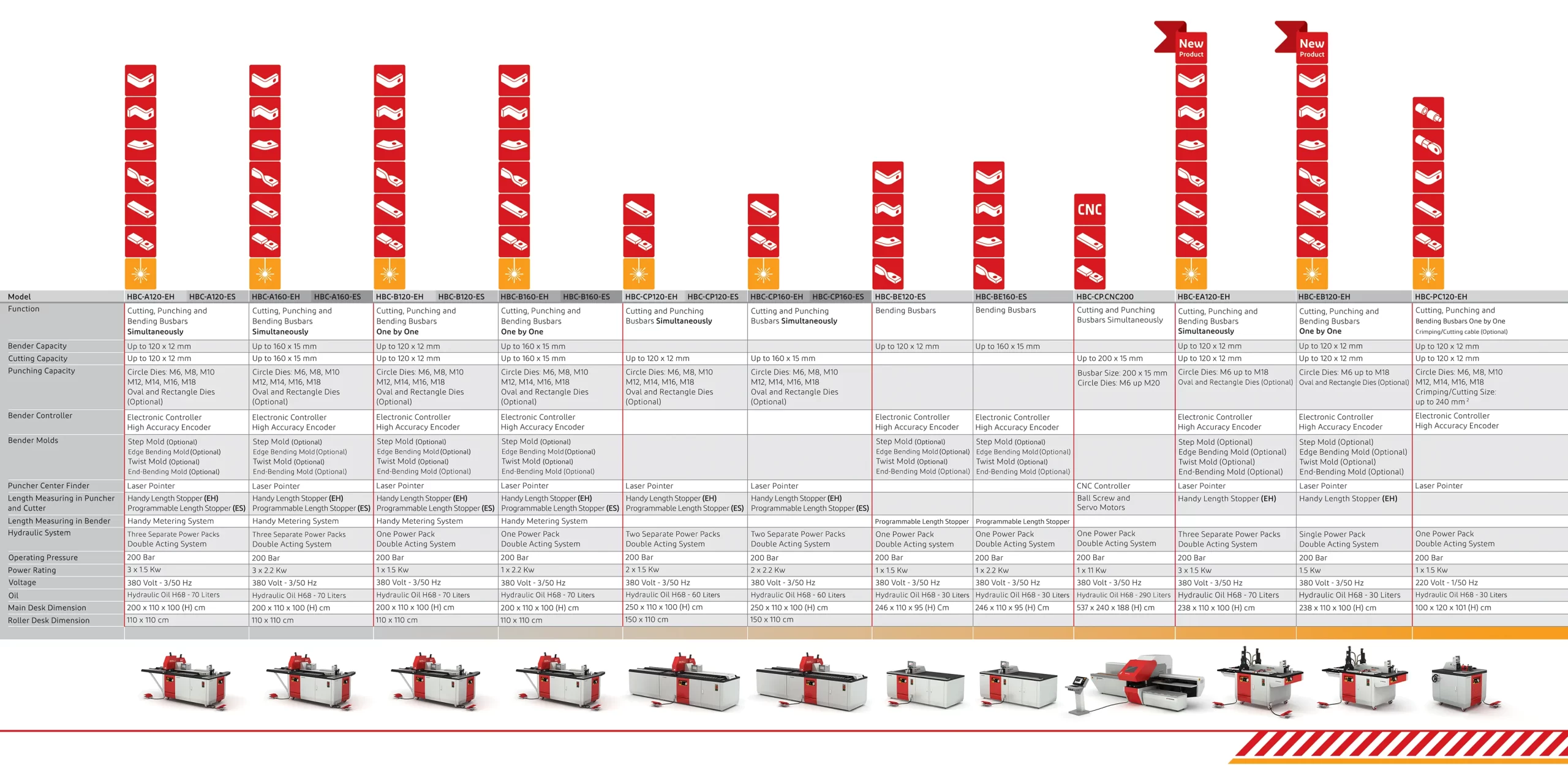

FIND YOUR BUSBAR SOLUTION

FAQ's

Frequently asked questions

How much is the cost of this device?

Round and square dies in many sizes, key lock louver, notching die, cable tray and etc. plus special molds which can be produced by order.

What is the maximum busbar size that can get operate on this machine?

The max dies dimension is 133Ø – 130 × 110 □

What is the "Programmable Length stopper"?

The punching stroke of this device is 70 mm adjustable

What type of oil does this device requires?

The punching power of this device is 16 ton

How can I get more Information about these machines?

PAYAPRESS will provide you with 2 years of warranty and 10 years of After-sales services.

If the Operator him/herself cause damage to the device, PAYAPRESS will not be responsible for it but if devices had issues on themselves our experts are ready to provide you with help 24/7.

NEED

CONSULTATION?

Feel free to contact us and

ask your question, its absolutely free.

"*" indicates required fields