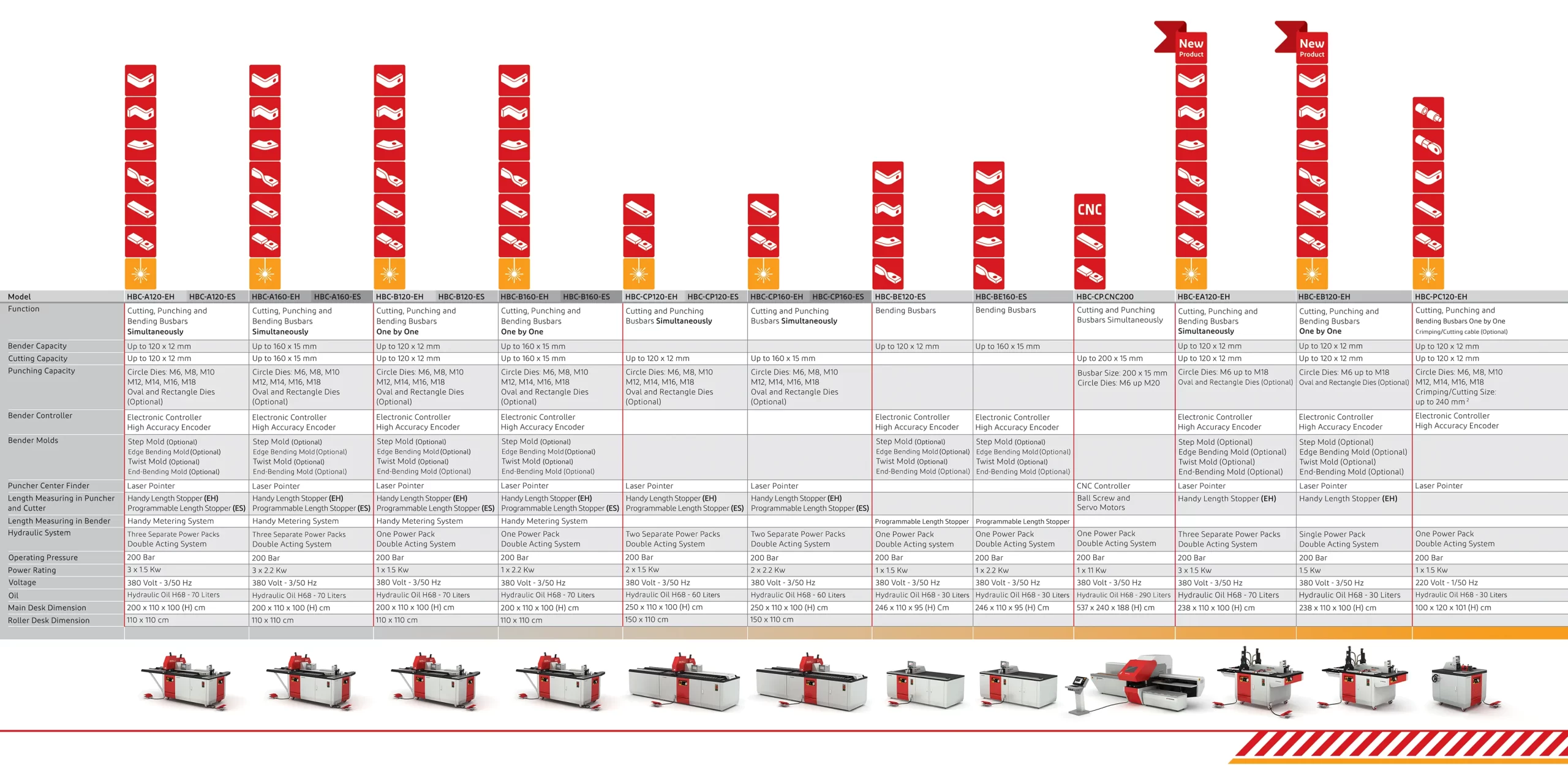

Bender station

To bend copper busbars up to 160*15 mm simultaneously

Digital controller for bender

To give instructions to the bender station to reach to perfect results

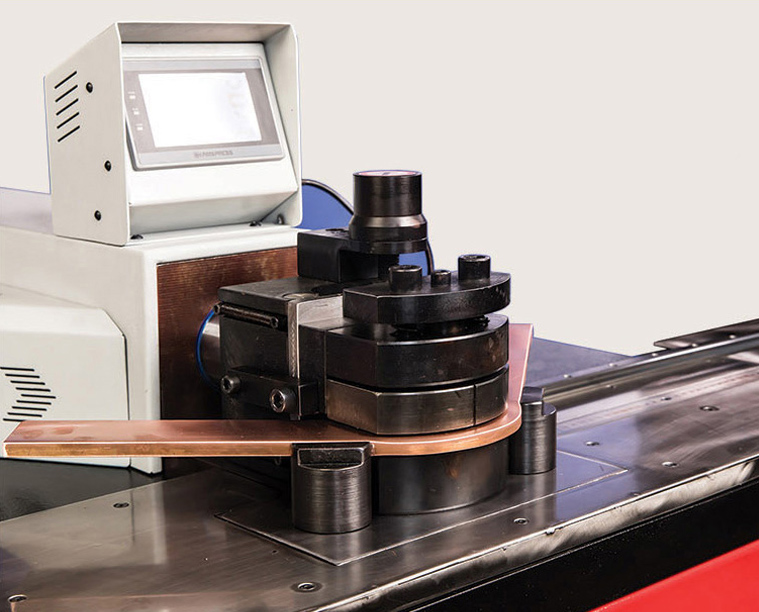

Digital controller for puncher and cutter

To give instructions to the puncher and cutter station to reach to perfect results

Puncher station

To punch copper busbars up to 160*15 mm simultaneously

Hydraulic Power Packs

Equipped with 3 power pack

Get a Free Quote

"*" indicates required fields

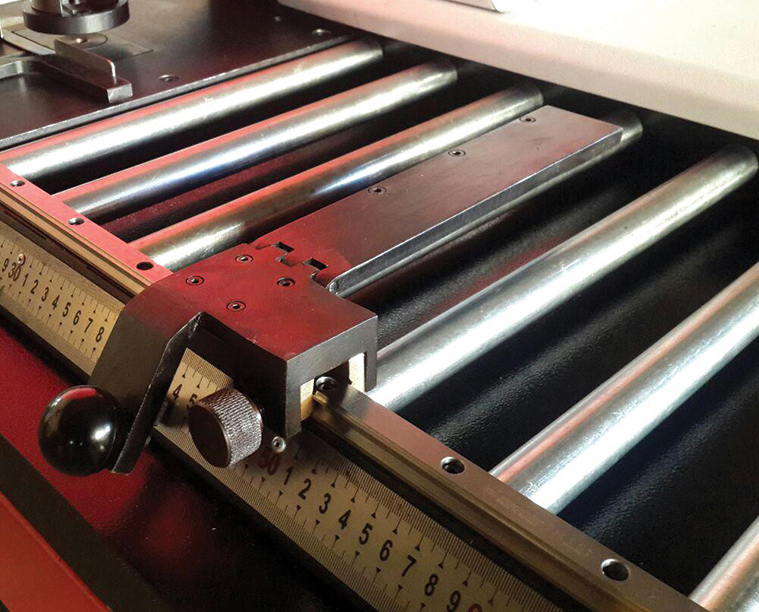

Model: HBC-A160 ES/EH

BUSBAR BENDING & PUNCHING MACHINES

3 in 1 Electrical Busbar Machine

INTRODUCTION

TECHNICAL INFORMATION

3 in 1 Busbar Machine Features

1- Copper puncher and cutter station of HBC-A160

The device in the puncher and cutter section is optionally equipped with programmable length stopper with the ability to save points required in a panel for the punching part along the X and Y axis as well as in the Y axis in the cutter station. Thus, by installing this option, there is no need to draw lines and points on copper busbars, also by reducing the operator’s intervention, human error in accuracy will be minimized. Also designing and manufacturing laser pointer in the puncher station of the device. increases the speed of the operation and the accuracy of the punching process, which the Payapress busbar processing machines have this capability along with the worldwide standards.

Punching is a key process in metal fabrication, used to create precise holes in copper busbars for electrical panels, ensuring accuracy and efficiency in switchboard manufacturing. It minimizes manual effort and enhances production speed.

2- Bending Station

The bender of this device is equipped with two independent systems to achieve bending with high precision and repeatability to repeat bending process in a high number of times.

1-Rotary measuring system:

A rotary encoder with a pulse factor of 3600 pulses per revolution in couple is directly connected to the movable rotating plates of the bender.

2-Linear measuring system:

A digital ruler consists of a magnetic strip and a digital receiver attached to the end of the piston rod measures and controls the advance rate of the piston in each bending process.

HBC-A160-EH | HBC-A160-ES | MODEL |

|---|---|

| Cutting ,Punching and Bending Busbars Simultaneously | Function |

| Up to 160 x 15mm | Bender capacity |

| Up to 160 x 15mm | Cutting capacity |

| Circle dies: M6 up to M18 Oval and Rectangle Dies (Optional) | Punching capacity |

| Electronic Controller High Accuracy Encoder | Bender controller |

| Step Mold (Optional) Edge Bending Mold (Optional) Twist Bending Mold (Optional) End-Bending Mold (Optional) | Bender Molds |

| Laser Pointer | Puncher center finder |

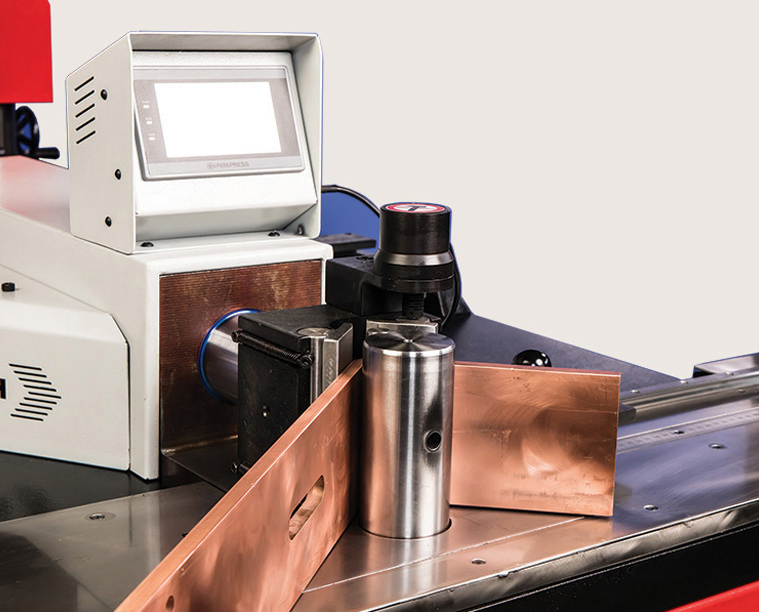

| Handy Length Stopper (EH) Programmable Length Stopper (ES) | Length measuring in puncher and cutter |

| Three Separate Power Packs Double Acting System | Hydraulic system |

| 200 Bar | Operating pressure |

| 3 x 1.5 Kw | Power rating |

| 380 volt – 3/50 Hz | Voltage |

| Hydraulic Oil H68 – 70 Liters | Oil |

| 200 x 110 x 100 (H) cm | Main desk dimension |

| 110 x 110 cm | Roller desk dimension |

FIND YOUR BUSBAR SOLUTION

FAQ's

Frequently asked questions

How much is the cost of this device?

HBC-A160 with an economical price is able to fulfill all of your needs regarding busbar processing. To get more information contact us through email or leave a message on website, our specialists will contact you ASAP.

What is the maximum busbar size that can get operate on this machine?

This device is capable of processing busbars Up to 15 × 160 mm

What is the "Programmable Length stopper"?

The programmable length stopper causes high accuracy in positioning of holes and cuts in puncher and cutter which is programmable for 20 positions.

What type of oil does this device requires?

The Type of oil that is used in this machine is Hydraulic Oil H68

How can I get more Information about these machines?

You can fill up the sections below and email us. our experts will help you ASAP.

the other way is to go to “contact us” and make a call or send an email to the mentioned email on the page.

NEED

CONSULTATION?

Feel free to contact us and

ask your question, its absolutely free.

"*" indicates required fields