International manufacturer PAYAPRESS produces high-efficiency generators at the upper end of the size , from 165 MVA upwards. The staple for these generator rotor coils is either solid drawn copper, or hollow profile copper bars, which are installed in sets, meaning tight bending tolerances are necessary. Read on to find out a few custom bus bar bending and punching solution that we developed together with PAYAPRESS’ engineers

The Bus Bar Challenge

Due partially to the tight tolerances and material being bent, distortion on the within edge on the brink of the bending point during production of parts posed a drag . within the past this had to be addressed before production could continue with another work tread on a second machine by pressing each side of the conductor. counting on the fabric composition, bending angle and bending radius, the result wasn’t consistently acceptable.

PAYAPRESS decided to take a position during a totally new bending technique to offer them enhanced efficiency and quality. Their goal was to scale back the work

steps from two on two machines to at least one on one machine, and thus to greatly improve productivity, accuracy repeatability and to realize greater flexibility by reducing tool changeover times.

view our Busbar machine Products

The Bus Bar Solution

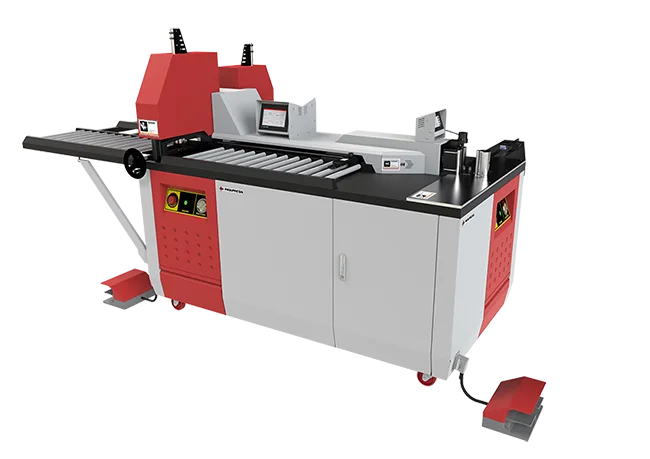

EHRT responded by collaborating with PAYAPRESS’ engineers to style and install a double axial bending machine that performed clamping, bending and pressing during a single machine.

Our solution involved two mirror-image bending presses that enabled machining of both ends of the conductor at an equivalent time. With one fixed unit and one moveable unit, an integrated length measurement system guarantees the accurate positioning of the moveable unit. When the staple is inserted, it’s positioned and clamped. The bending process then takes place at both ends. Our patented spring-back compensation system takes care of any spring-back.

The material distortion that was previously fixed with a secondary process is straightened out at both ends simultaneously by the press unit, and therefore the bent angle is checked again. The accuracy of the bent angle obtained by this method is 0.15o, the fabric distortion after pressing is merely a maximum of 0.04mm. the entire process time for a conductor is well under a moment , and therefore the complete production process is automated.

Our team was successful in condensing the two-step machining process, formerly using two machines, into one process on one machine. This also reduced the inaccuracies by a few factor of 10, because the conductor is now firmly clamped in situ during the entire procedure.

The operator not has got to waste time positioning the piece for each bending and punching step, which led to inaccuracies. Tool-changing times are radically reduced by our easy-to-change tooling system. This new machine has saved over 90 working hours just within the production of the rotor conductors for one generator. That’s a considerable savings!

If you’re trying to find an ingenious solution to a bus bar fabrication challenge, contact us today. we glance forward to helping design an ideal solution for your unique application.

No comment