Last updated: August 2025 — By: Technical Team, Busbar Fabrication (reviewed by a senior electrical engineer; sources include Copper Alliance, IEC, UL).

If your switchboard or power electronics layout demands bends that standard catalogs don’t cover—edgewise turns, tight offsets, torsional twists, or integrated punch→bend workflows—you need a custom busbar bending solution. This guide shows how to define one that’s practical to build, easy to inspect, and compliant with assembly rules. You’ll find clear bend-type definitions, minimum bend radius guidance with sources, quality/tolerance considerations, and a copy-ready RFQ checklist to accelerate quoting.

What a custom busbar bending solution includes

A robust solution isn’t only about making angles; it’s about repeatability under real-world shop conditions. Typical elements include:

- Right bending platform (CNC or hydraulic) matched to your volume, geometry mix, and team skills.

- Custom tooling/fixtures for edgewise, offset, torsional, or layered bends.

- Angle control & springback compensation, ideally with encoder feedback on CNC systems.

- Surface-protection strategy (films/shims/radiused clamps) to prevent clamp/roller marks on conductive faces.

- Inspection plan covering angle, radii, leg lengths, twist/flatness, and cosmetics.

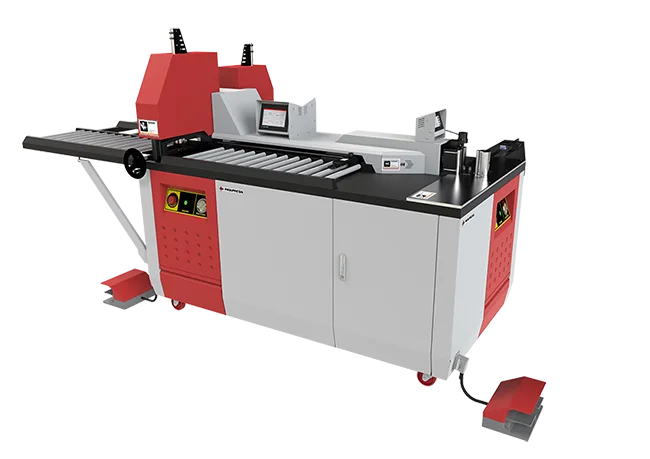

Market-available machines and cells commonly cover flat, offset, edgewise, twist, and U/Z bends; vendors also integrate punching, countersinking, marking, and thread forming in the same flow for throughput. For an overview of why integrated systems matter, see The Advantage of 3-in-1 Busbar Machines.

Busbar bending types: flat, edgewise, offset, U/Z, torsional

Flatwise bends are the everyday L/U/Z geometries. Edgewise bends rotate the bending axis to accommodate taller sections or panel constraints. Offset bends step over obstacles while holding plane alignment. Torsional (twist) bends rotate a pad about the bar’s longitudinal axis to meet terminal orientation. Layer/space bending addresses multi-bar stacks. Custom-solution vendors highlight further variants (e.g., space bending, combination bends) and can incorporate springback compensation when approaching tight angles.

Minimum bend radius for copper busbars (with sources)

Your minimum bend radius (Rmin) is a core spec. It depends on thickness (t), temper (e.g., annealed vs half-hard), and die radius. A widely used reference for high-conductivity copper suggests:

- Up to 10 mm: Rmin ≈ 1×t

- 11–25 mm: Rmin ≈ 1.5×t

- 26–50 mm: Rmin ≈ 2×t

Always validate on your actual material and die set, especially near tight radii or cosmetic-critical surfaces. Formability is a trade-off against strength—cold-worked material (higher strength) tends to bend less easily—so Rmin is expressed as a multiple of thickness and “harder” tempers may require larger radii or localized annealing.For practical shop tips, see our new guide Bending Copper Busbar: How to Hit Minimum Radii, Avoid Marks, and Control Springback.

Springback and angle compensation

Springback occurs when the material elastically recovers after unloading. To hit nominal angles:

- Match die radius to your target Rmin (too small risks surface cracking; too large increases springback).

- Use encoder-based angle control with iterative compensation on first-article coupons.

- Record a springback factor in your program so subsequent parts repeat.

- For critical geometries, verify with radius gauges and an angle protractor or digital arm.

CNC vs hydraulic: which platform fits your job?

CNC bending systems excel at repeatability, angle feedback, and fast changeovers across many part numbers—often integrated into automated cells with marking and downstream operations for high throughput.Hydraulic bench / 3-in-1 systems are cost-effective for moderate volumes and broader shop tasks (cut-punch-bend). Setup skill matters more; add fixtures/stop-systems for repeatability.

Buying soon? Get realistic ranges and TCO guidance in Busbar Bending Machine Price (2025): Practical Guide and the broader Busbar Machine Price Guide.

Quality, tolerances, and surface protection in busbar bending

Surface condition affects both conductivity and fit. Use films, shims, or radiused clamps to avoid marking, especially on visible or bolted faces. Deburr edges before contact areas are formed. Keep an inspection checklist for:

- Angles & radii (gauge or template)

- Leg lengths & offsets (steel rule/calipers)

- Twist/flatness for edgewise and torsional bends

- Cosmetics (scratches, clamp marks)

For stacked or complex bends, full-scale drawings/templates help avoid compounding errors.

Standards context: designing within assembly rules

Even a perfect bend must live inside an assembly standard. IEC 61439-1 (2020) defines the general rules and verification framework for low-voltage switchgear/controlgear assemblies—your finished bar must meet the assembly’s construction and verification requirements.In North America, UL 508A includes guidance on supporting live parts (e.g., busbar standoffs, insulating barriers) and component acceptance; ensure your supports/barriers remain compliant after adding offsets/layers.

If your projects involve UL switchboards, you may also find our explainer useful: Industrial Switchboard (UL 891) — Plain-English Guide for Engineers.

Custom Busbar Bending Planner

| Geometry / Feature | Typical benefit | Best for (material/size) | Throughput impact | Repeatability focus | Tooling / fixture note | Validation / inspection note |

|---|---|---|---|---|---|---|

| Flatwise bends | Standard L/U/Z parts | Cu/Al up to shop capacity | High | Angle control, springback | Match die radius to spec | Check angle on first-articles; log springback factor |

| Edgewise bends | Narrow width, tall section | Stiff bars that risk twist | Medium | Back-gauge alignment | Edge support & anti-twist | Verify parallelism/planarity after bend |

| Offset bends | Clearance over obstacles | Panel layout constraints | Medium | Stop accuracy | Dedicated offset tooling | Measure offset height and leg lengths |

| Torsional (twist) bends | Rotational alignment of pads | Terminal orientation needs | Low–Medium | Angular index accuracy | Torsion tool with stops | Confirm twist angle with template |

| Layer/space bending | Multi-layer stacks | Compact switchgear | Medium | Stack squareness | Pressure plates/packers | Inspect stack gaps & mark-free surfaces |

| Tight radii (near Rmin) | Compact routing | Thin/annealed Cu preferred | Medium | Surface marking risk | Larger die radius; films/shims | Visual + radius gauge; consider NDT if critical |

| Integrated punch→bend flow | Fewer setups, ID traceability | Repetitive parts libraries | High | Tool path + program control | Shared datum strategy | First-piece FAIR; record CP/CPK where needed |

Notes: “Throughput” and “Repeatability” are qualitative. For high-conductivity copper, indicative Rmin: up to 10 mm ≈ 1×t, 11–25 mm ≈ 1.5×t, 26–50 mm ≈ 2×t—validate on your material and dies.

RFQ checklist for a custom busbar bending solution

- Material & temper: Copper/Aluminum; grade; half-hard/annealed.

- Bar size range: Thickness × width; max length.

- Bend types: Flat / Edgewise / Offset (height) / U / Z / Torsional (angle).

- Radii & angles: Target Rmin; ± angle tolerance; leg lengths.

- Sequence: Punch-then-bend, or bend-then-punch; datum strategy.

- Surface protection: Films/shims; mark-free faces.

- Inspection: First-article plan; gauges; documentation.

- Throughput: Parts/hour; mix (no. of SKUs/shift).

- Integration: Marking, countersink/thread forming, measurement.

- Compliance context: IEC 61439-1 / UL 508A; supports/barriers.

What to read next

- Busbar Bending Machine Price (2025): Practical Guide

- Busbar Machine Price Guide: Comprehensive Cost Reference

- The Advantage of 3-in-1 Busbar Machines

- Industrial Switchboard (UL 891) — Plain-English Guide for Engineers

- Bending Copper Busbar: How to Hit Minimum Radii, Avoid Marks, and Control Springback

FAQs

What is the minimum bend radius for copper busbars?

Indicative guidance for high-conductivity copper: up to 10 mm ≈ 1×t, 11–25 mm ≈ 1.5×t, 26–50 mm ≈ 2×t—validate on your material and dies.

Can aluminum busbars be bent the same as copper?

Formability and springback differ; adjust tooling/clamping and validate radii on coupons before production.

How do you control springback?

Use appropriate die radii, encoder-based angle control, and calibration bends; verify on first-article samples.

Should punching happen before or after bending?

Many shops punch first to protect hole quality and simplify locating, but confirm sequence with your tolerances/fixtures.

Which is better: CNC or hydraulic?

CNC improves repeatability and changeover for high-mix work; hydraulic benches suit lower volumes and simpler geometries.

References

- Copper Alliance. Copper for Busbars — Guidance for Design and Installation (2019), Table 6.

- Copper Development Association. Industrial Design Guide — Formability (minimum bend radius concept).

- IEC. IEC 61439-1:2020 overview.

- UL. UL 508A — Supplement SA (2019/2022).

- Rittal. RAS Busbar Modification Machines (capabilities).

- EHRT. Automated Bus Bar Production Cell (custom solutions).

- Gensco. Busbar Processing Machines (3-in-1 systems).

- Electrical Engineering Portal. Shaping and connecting rigid busbars.