If you work with low voltage power distribution, you will meet the industrial switchboard very often. This guide explains the basics in simple language so you can choose, size, and specify correctly. We cover UL 891, the key NEC Article 408 ideas, and the differences between switchboard, switchgear, and panelboard.

Alternatively, an audio version of this article is available below for your convenience.

What is an industrial switchboard?

An industrial switchboard is a floor-standing enclosure that takes one incoming power feed and splits it into many branch circuits.

Inside, you usually have a steel frame, copper or aluminum busbars (horizontal and vertical), an incoming section, meters, surge protection, and overcurrent devices like molded-case circuit breakers (MCCBs).

Dead-front covers allow safe access to devices while keeping live parts behind barriers. Typical ratings are up to 600 V and bus up to 6000 A.

Standard short-circuit withstand for many designs is 65 kA at the incoming terminals, and higher (for example 100–200 kA) is possible with approved main devices and tested combinations.

UL 891 in simple words

UL 891 is the U.S. product standard for dead front distribution switchboards rated 600 V or less.

It defines construction and test requirements so the assembly is safe and robust.

Manufacturers perform Factory Acceptance Tests (FAT) to check wiring, clearances, insulation, mechanical strength, and operation of devices.

When you request a quote (RFQ), say clearly that you need a “UL 891 listed and labeled switchboard.” This helps the vendor design and document correctly from day one.

If you want a deeper, step-by-step explanation of requirements, labels, and what to ask vendors, this industrial switchboard UL 891 guide expands the main UL 891 points in plain language.

UL 891 switchboard: listed, labeled, and truly “dead-front”

A UL 891 switchboard is not “basically compliant because it looks like one.” If you need a UL 891 listed and labeled assembly, you are buying a product that has to meet specific construction and test requirements for a UL 891 dead front switchboard (live parts behind barriers, safe access to operating handles, proper spacing, insulation, and mechanical integrity). In your RFQ, call it out exactly: “UL 891 switchboard, listed and labeled” and ask for the nameplate data, label location, and the documentation package that matches the as-built equipment. People will search UL891, UL 891 online, or even “UL 891 ebook / UL 891 epub” to read the standard, but procurement-wise the only thing that matters is: you reference the current edition and require the vendor to deliver a switchboard that is actually listed and labeled under UL 891 switchboards requirements.

Industrial switchboard: sizing the bus, sections, and fault ratings without guessing

For an industrial switchboard, sizing starts with the boring stuff that prevents expensive mistakes: voltage/system, calculated load, main device type (main breaker vs main lugs), and realistic future expansion space. Then lock down the two fault numbers that decide whether the gear survives a bad day: the assembly SCCR (at the incoming terminals) and each breaker’s AIC (at its installed point). If your short-circuit study says the available fault current is 65 kA, your industrial switch board must have an SCCR ≥ 65 kA, and every breaker installed where the fault is high must have AIC ≥ available fault current. Put those values directly into the RFQ along with bus rating/material (Cu/Al), section layout (incoming, metering, surge, feeders), and enclosure type (NEMA/IP) so the vendor designs the whole lineup correctly instead of playing electrical roulette.

NEC Article 408 — site rules that matter

NEC 408 covers panelboards, switchboards, and switchgear. For day to day work, focus on three ideas:

(1) install straight, plumb, and accessible with proper working space;

(2) avoid hazardous or corrosive locations unless the enclosure is rated for that environment;

(3) for service-entrance switchboards (fed directly by the utility), follow the utility’s grounding and bonding requirements.

Good layout now saves headaches during inspection and maintenance later.

Busbar design choices affect temperature rise, fault performance, and how cleanly branch circuits land in the field. This quick overview of busbar systems inside power switchboards helps connect bus structure to real-world distribution performance.

Switchboard vs switchgear vs panelboard

You choose switchgear when you need higher continuity of service and easier breaker maintenance under energized conditions.

*Panelboard vs switchboard:* A panelboard is wall mounted, smaller, and often ≤1200 A; breakers usually snap onto the bus.

A switchboard is floor-standing, handles higher amperage up to 6000 A, and often uses bolted-on breakers.

Pick based on load level, maintenance approach, and space in the electrical room.

Not every busbar layout is “standard,” and tight clearances can force special bend geometries. If you need unusual shapes or repeatable angles, check a custom bending solution for busbar machine for ideas on specifying bending outcomes clearly.

Ratings that really matter

SCCR (Short-Circuit Current Rating) is the maximum fault current the entire assembly can safely withstand at its incoming terminals.

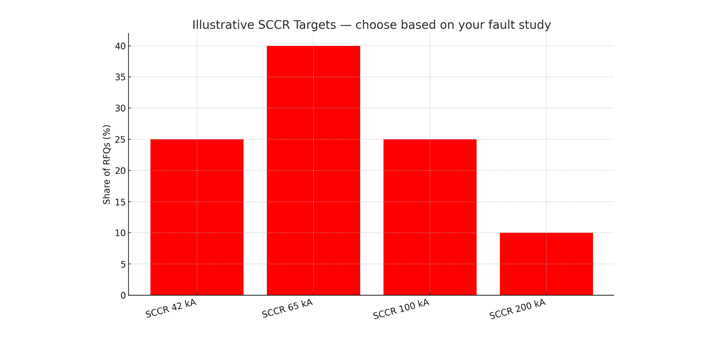

Common labels are 42 kA or 65 kA, and some projects require 100–200 kA. The right value depends on your short-circuit study.

AIC (Ampere Interrupting Capacity) is a breaker rating; each breaker must be able to interrupt the available fault current at the point where it is installed.

Always match the breaker’s AIC to the calculated fault current so it can clear safely.

Enclosures: NEMA vs IP

For indoor dry locations in the U.S., NEMA Type 1 is typical. For outdoors, NEMA 3R is common.

If the site is dusty or wash-down, look at higher NEMA types or IP66.

Choose the enclosure rating to fit the environment and local code.

If your switchboard project includes sheet-metal enclosures, corner quality affects alignment, sealing, and long-term durability. See how a weld-free approach improves consistency with a corner forming machine

For low-voltage power distribution, get the switchboard spec right by aligning the product with its standard and the site code: state “UL 891 listed & labeled” in your RFQ, match the enclosure rating to the environment (NEMA/IP), and confirm the assembly SCCR meets or exceeds available fault current while each breaker’s AIC is adequate. For an authoritative source, see UL’s overview of the UL 891 switchboard standard, which explains the scope and intent of the listing and testing requirements.

Sizing and arc-flash basics

Start with a load calculation. Select the main device main breaker or main lugs for the total calculated load, and leave space for future expansion.

For arc-flash safety, follow your site study or NFPA 70E-CSA Z462 tables, use the correct PPE, and consider features like energy-reduction maintenance settings, IR windows, and remote operation where available.

Good documentation single-line, layout, nameplate data makes installation and commissioning smoother.

Conclusion

An industrial switchboard is the backbone of low-voltage power distribution, but it only performs well when it is specified correctly. For most U.S. projects, the safest path is to request a UL 891 switchboard, specifically a UL 891 dead front switchboard, so construction, testing, and labeling line up with a recognized product standard. In the RFQ, state clearly that you need UL 891 listed & labeled equipment (many engineers also write UL891 as shorthand), and make sure the vendor’s documentation and nameplate data match the final as-built lineup.

Then align the installation with NEC Article 408, choose the right enclosure rating (NEMA or IP) for the environment, and verify fault protection by confirming the assembly SCCR and each breaker’s AIC against your short-circuit study. When these basics are clear in the RFQ, procurement moves faster, inspections go smoother, and maintenance stays predictable for years.

“I’ve been working with industrial switchboards for over a decade, and this article really hit the mark. The breakdown of UL 891 standards and NEC Article 408 made it easy to understand the key compliance issues we face every day. The explanation of SCCR and AIC ratings was straightforward and helpful—these are often confusing, but this guide made it clear. I also appreciate the focus on custom bending solutions for busbars; that’s something we don’t see enough of in similar content. Definitely bookmarking this one for future reference!”