Last updated: oct 2025

Author: Technical Editorial Team

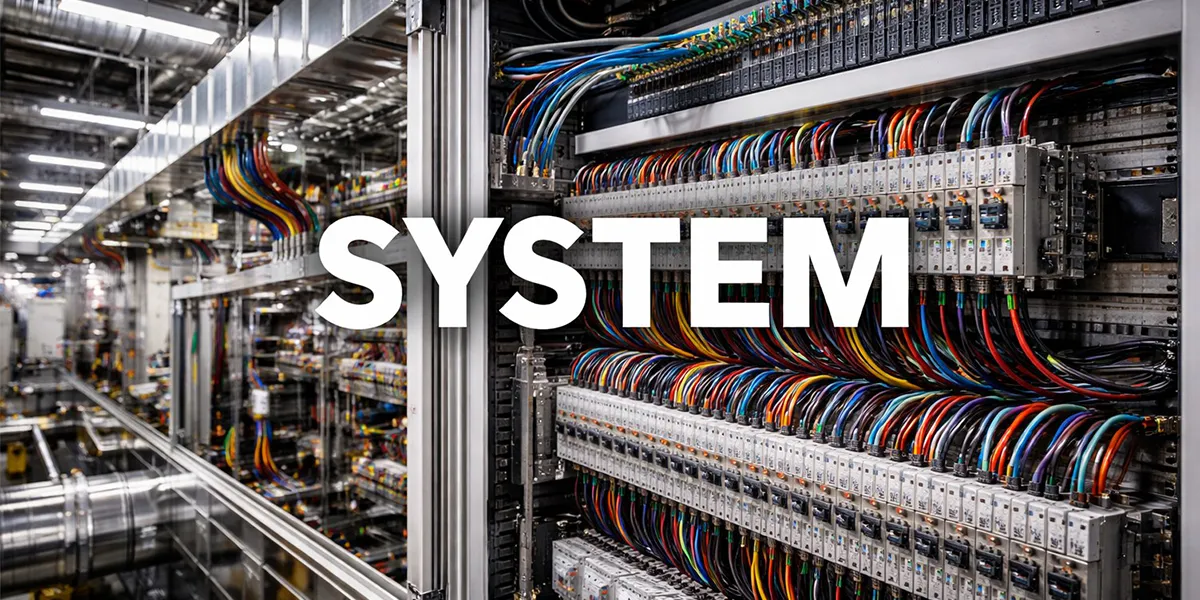

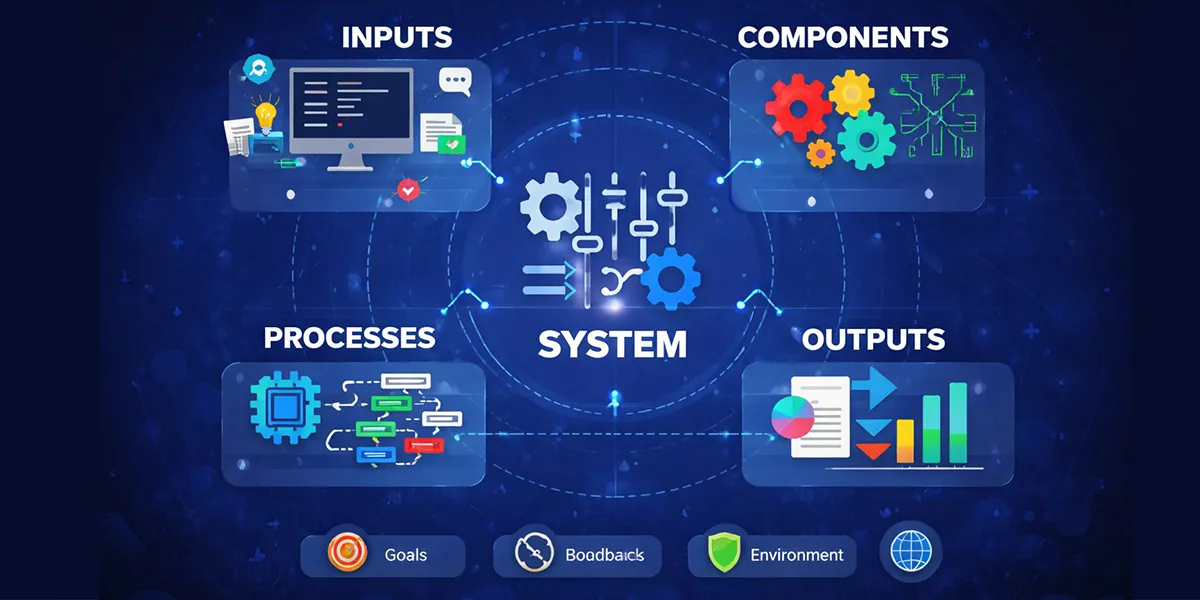

Busbar systems are the backbone of low-voltage power switchboards, carrying and distributing high currents safely while keeping heat rise, short-circuit forces, and footprint under control. This guide explains how busbars are arranged inside switchboards, the trade-offs between copper and aluminum, verification and compliance requirements, and how to choose the right configuration for new builds or retrofits.

What a Busbar System Does Inside a Switchboard

Inside a power switchboard (IEC or UL frameworks), the busbar system:

Carries rated current across sections with acceptable temperature rise (verified by test or design as required by IEC 61439-1/-2). (ABB IEC 61439 workbook, 2016)

Withstands short-circuit stresses and remains mechanically secure (bracing, supports, validated by type/routine verification under IEC or UL routes). (ABB IEC 61439 workbook, 2016)

Provides safe segregation and accessibility for maintenance (e.g., internal arc classification options per IEC/TR 61641 for enhanced operator safety). (ABB MNS switchgear page, 2025)

Standards and Compliance (What Must Be Proven)

IEC assemblies (global markets): IEC 61439-1/-2 requires verification of temperature-rise limits, dielectric properties, clearances/creepage, short-circuit withstand, and mechanical strength. Verification may be by testing, measurement/calculation, or design rules, depending on the characteristic. (ABB IEC 61439 workbook, 2016; Electrical Engineering Portal summary, 2021)

UL assemblies (North American markets): UL 891 covers dead-front switchboards up to 1000 V with marking of short-circuit current rating (SCCR) and construction/spacing rules. (Coast Label UL 891 guide, 2025; ComplianceGate UL 891 overview, 2023)

Internal arc options: Many modern IEC switchboards offer IAC (Internal Arc Classification) per IEC/TR 61641 for personnel protection. (ABB MNS switchgear page, 2025)

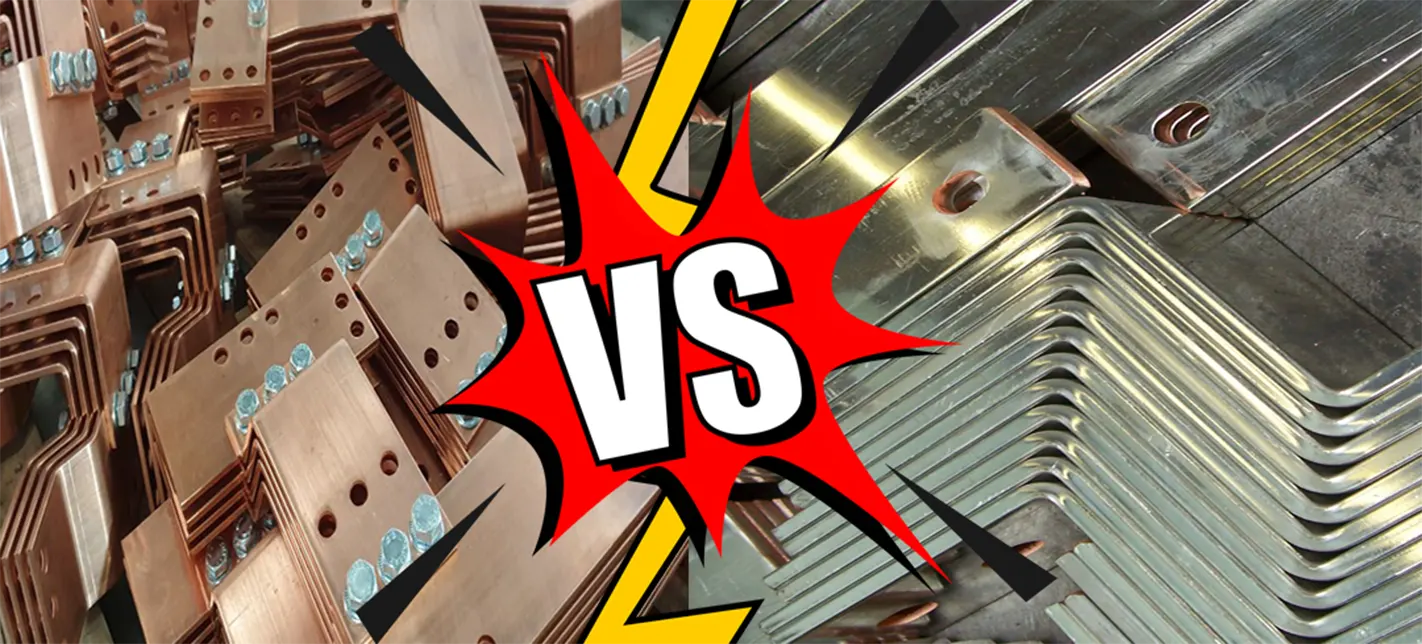

Copper vs. Aluminum Inside the Enclosure

Copper offers higher conductivity and stable joints; favored for compact layouts and high-cycle connections.

Aluminum can lower weight and material cost at the expense of a larger cross-section for the same current. Where Cu–Al interfaces are unavoidable, use listed bimetallic transition hardware and follow torque/cleaning practices to avoid galvanic corrosion and oxide-related heating. (ICC Code E3406.8, 2015; Hubbell connector application guide, ~2018; RHI Electric bimetal guidance, 2025)

Practical tip: when connecting aluminum conductors to copper busbars (or vice-versa), use bimetallic lugs/plates that are listed for Cu–Al transitions; clean and prepare surfaces and apply anti-oxidation compound per the device instructions. (ICC; Hubbell; RHI Electric, 2025)

Typical Layouts You’ll See

Horizontal main with vertical risers (air-insulated): The most common architecture for form-segregated boards.

Sandwich/encapsulated busbars (insulated): Higher power density and improved short-circuit behavior in a compact footprint.

Single vs. double main bus: Double main aids redundancy and maintenance flexibility in critical facilities.

Rear or top bus placement: Driven by cable/bus duct entry, service corridor space, and thermal management.

Vendor data points for scale (indicative, varies by model/testing program):

ABB MNS (IEC): Main busbar up to 7,300 A with IAC options (IEC 61439-2 / IEC TR 61641). (ABB MNS page, 2025 — indicative)

Eaton switchboards (UL/IEC): Main bus up to 6,000 A configurations available. (Eaton switchboard overview, 2023 — indicative)

Thermal Rise and Short-Circuit Forces (Why Bar Size and Bracing Matter)

Thermal: Bar size, spacing, and ventilation must keep temperature rise within IEC/UL limits; verification is mandatory. (ABB IEC 61439 workbook, 2016)

Electromechanical: Short-circuit forces scale with I²; adequate bracing/insulation supports, plus verified clearances, prevent deformation and flashover. (ABB IEC 61439 workbook, 2016)

Material Cost Context (Market-Driven)

Raw material markets influence total cost of ownership (TCO). As a snapshot (monthly averages, indicative and subject to change):

Copper: US$ 9,771/metric ton (Jul 2025)

Aluminum: US$ 2,606/metric ton (Jul 2025)

(World Bank “Pink Sheet” Metals, Aug 2025)

Cost isn’t the only driver; consider footprint, losses, joint reliability, and long-term maintenance.

High-Utility Selection Table (Ready to Use)

The table below helps narrow a configuration during pre-spec. Ratings are indicative; always confirm against the selected manufacturer’s type tests and the project’s standard (IEC or UL).

| Decision Factor | Air-Insulated Bus (AI) | Sandwich/Encapsulated Bus | Copper Busbar | Aluminum Busbar |

|---|---|---|---|---|

| Typical main bus rating (indicative) | Up to 6,000 A in mainstream LV boards (Eaton, 2023) | Up to 7,300 A in high-density IEC boards (ABB MNS, 2025) | Smaller cross-section for a given ampacity; compact layouts | Larger cross-section for same ampacity; lower mass |

| Short-circuit performance | Depends on bracing and spacing; verified per IEC 61439/UL 891 | Generally strong electrodynamic behavior due to encapsulation | Good joint stability; less creep | Use listed Cu–Al transitions; manage creep/oxide at joints |

| Thermal behavior | Requires spacing/ventilation to meet temp-rise limits | Better heat spreading; compact heat paths | Higher conductivity; lower I²R losses for same section | Higher section to match losses; attractive material cost |

| Internal arc (operator safety) | Available on select systems; check IAC classification | Available on select systems; check IAC classification | — | — |

| Cost and availability | Standard build for many boards | Premium/compact; may add cost | Raw material higher (Cu: US$ 9,771/mt, Jul 2025) | Raw material lower (Al: US$ 2,606/mt, Jul 2025) |

| Recommended use cases | General purpose LV switchboards, spacious rooms | High-power density, space-constrained rooms | Critical power, high cycling, compact MCCs | Cost-sensitive projects with ample space |

Notes: Ratings are indicative snapshots from vendor literature and depend on specific system design and testing. Material prices are indicative World Bank monthly averages (USD per metric ton) and change over time.

Sources: ABB MNS (2025), Eaton Switchboards (2023), ABB IEC 61439 Workbook (2016), World Bank Pink Sheet (Aug 2025).

Joints, Connections, and Mixed-Metal Interfaces

Only use devices/connectors listed for Cu–Al transitions when joining copper and aluminum conductors/busbars; this is a code expectation in many jurisdictions. (ICC E3406.8, 2015)

Avoid bare Cu–Al contact; use bimetallic lugs/plates and follow the manufacturer’s cleaning and anti-oxidation procedures. (Hubbell connector application guide, ~2018; RHI Electric, 2025; TE Connectivity/industry catalog examples)

Torque and retightening: Follow the switchboard maker’s torque schedule. Many modern systems design joints to be “maintenance-light,” but visual/thermal scans during outages remain best practice. (Schneider Electric blog guidance, 2019; EEP maintenance notes, 2021)

Comparing the Benefits of Copper vs Aluminum Busbar Systems

When it comes to choosing the right material for electrical busbar systems, both copper and aluminum offer unique advantages that are critical in various applications. Copper, renowned for its superior conductivity, is a preferred choice for electrical busbar systems requiring high efficiency and minimal energy loss. On the other hand, aluminum busbar systems provide a lightweight, cost-effective solution, making them ideal for projects where weight and budget constraints are key factors.

Understanding the Importance of Material Selection in Busbar Systems

Choosing between copper vs aluminum busbar systems depends on several factors such as current capacity, system design, and environmental conditions. Copper bus duct trunking systems excel in scenarios that demand high power transmission and longevity, due to copper’s resistance to corrosion and high conductivity. In contrast, aluminum bus systems offer flexibility and are highly effective for low to medium-power applications where reduced weight and material costs are prioritized. By understanding these distinctions, engineers and decision-makers can ensure the optimal performance of their electrical systems, achieving the best balance between cost-efficiency and durability.

Maintenance Cues (In-Service)

Visual checks for discoloration at joints/insulators, IR thermography after major load changes, and mechanical inspection after any fault event. (EEP, 2021)

Internal arc mitigation (where available) adds a safety layer but does not replace proper PPE and LOTO procedures. (ABB MNS, 2025)

Procurement & Fabrication Notes (Fewer Headaches Later)

Keep conductors straight and burr-free to preserve clearances/creepage.

Use consistent bend radii and hole patterns to speed assembly and reduce stress concentrations. In-house precision helps:

Busbar Bending Machine – repeatable bends for tight panels

Busbar Punching Machine – clean holes reduce hot-spot risk

Busbar Cutting Machine – square cuts help joint quality

Busbar Machine (3-in-1) – integrated bend/punch/cut for shop efficiency

RFQ Checklist (Copy into Your Spec)

Standard & market: IEC 61439-1/-2 (IAC yes/no) or UL 891 (SCCR target ___ kA).

Main bus rating ___ A; material Cu / Al; layout AI / Sandwich.

Temperature-rise verification method (test / design rule / assessment).

Short-circuit withstand rating and bracing details.

Segregation/form of separation; cable/bus duct entry path.

Cu–Al transitions required? Yes/No (specify bimetallic hardware).

IR scanning window(s) and maintenance access clearances.

Factory routine tests and documentation pack.

FAQs

What standard governs low-voltage switchboards internationally?

IEC 61439-1/-2 defines construction and verification for low-voltage switchgear and controlgear assemblies. (ABB IEC 61439 workbook, 2016; EEP summary, 2021)

What about North America?

UL 891 covers dead-front switchboards up to 1000 V, including required SCCR marking. (Coast Label, 2025; ComplianceGate, 2023)

Is aluminum acceptable inside a switchboard?

Yes—when sized correctly and using listed Cu–Al transition hardware for any mixed-metal joints, aluminum can reduce mass and material cost. (ICC; Hubbell; RHI Electric, 2025)

How do I reduce hot spots?

Use properly prepared joints (cleaned, oxide-managed), correct torque, adequate surface area, and verify temperature rise per standard. (Hubbell; ABB workbook)

Are internal arc-rated boards required?

Not always; they’re a risk-reduction option. Many IEC systems (e.g., ABB MNS) offer IAC ratings; assess based on hazard analysis. (ABB MNS, 2025)

Sources

ABB. MNS Low-Voltage Switchgear – IEC/EN 61439, IEC/TR 61641 (accessed Aug 2025).

ABB. IEC 61439 Low-Voltage Switchgear and Controlgear Assemblies – A Practical Workbook (2016).

Electrical Engineering Portal. Quick Guide to IEC 61439 (2021).

Coast Label. UL 891 Power Switchboards Overview (2025).

ComplianceGate. UL 891: Overview and Requirements (2023).

Eaton. Switchboards Overview (2023).

World Bank. Pink Sheet – July 2025 Monthly Metals Prices (Aug 2025).

ICC. E3406.8 Aluminum and Copper Connections (2015).

Hubbell. Connector Theory and Application (~2018).

RHI Electric. Copper to Aluminium Busbar: Transition Joints (2025).

(All figures are indicative; specifications and prices change over time.)