Switchboard Busbar

Last updated: August 2025

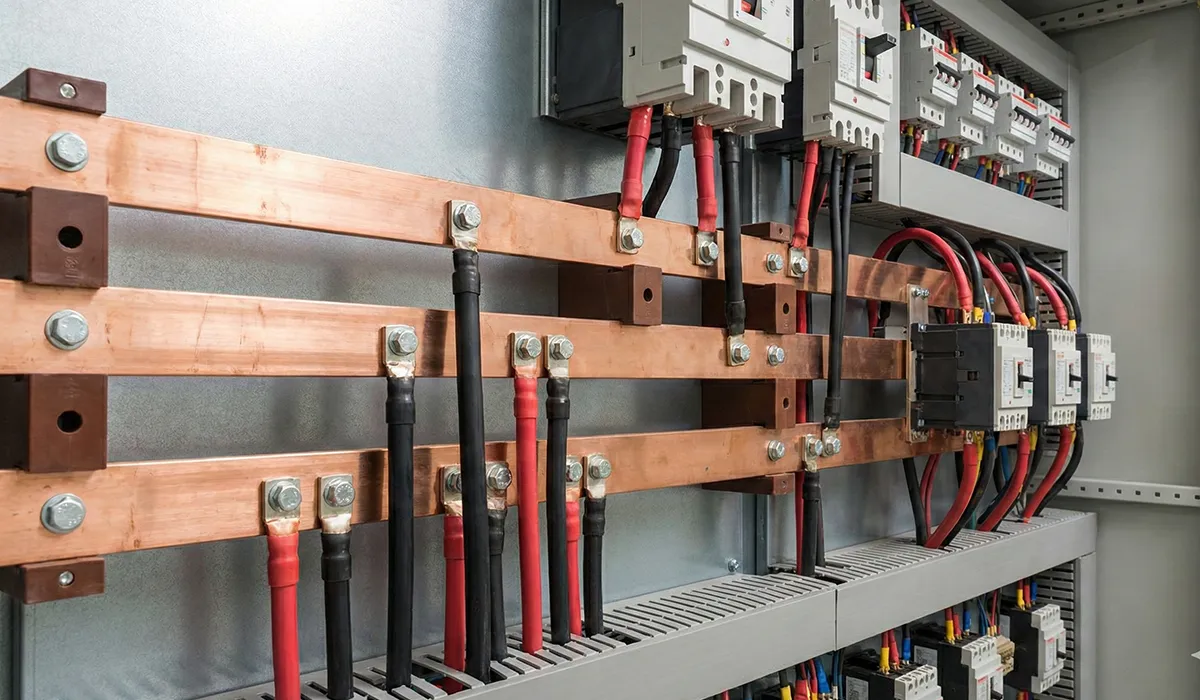

Busbars are the backbone of a low-voltage switchboard: rigid conductors that collect and distribute current safely between incoming devices and outgoing feeders. In most assemblies you will find horizontal main bars, vertical risers, neutral and equipment-ground buses, and purpose-designed supports/insulators that hold everything in place under thermal and electrodynamic stress. In short, the switchboard busbar is where mechanical design, materials science, and electrical codes meet.

What is a switchboard busbar (and how it works)

A busbar is a metallic bar or strip—typically copper or aluminum—mounted inside switchgear/switchboards to distribute high currents. Flat profiles maximize surface area for cooling and make joints easier to bolt and plate. Depending on construction, the bars may be bare or insulated (e.g., heat-shrink sleeve or epoxy coating), and they’re supported on insulators with defined creepage/clearance distances.

For fundamentals and fabrication context, see our primers: The role of busbars in modern electrical systems and Busbar bending techniques (design & quality).

Switchboard busbar vs. busbar trunking (IEC 61439-6)

“Power busbar” can mean different things. Internal switchboard busbars are part of an assembly verified to IEC 61439-1/-2 (global) or UL 891 (North America). By contrast, busbar trunking systems (busways) are separate enclosed products used to distribute power around a facility and verified to IEC 61439-6. If you’re specifying a switchboard that connects to busway, reference both regimes—the switchboard for its internal busbars, the busway for the external distribution.

Helpful overviews: ABB: The IEC 61439 standard in practice, UL: UL 891 program page, and nVent Hoffman: IEC 61439 overview.

Copper C110 vs. Aluminum 6101 busbars (ASTM-based comparison)

Material choice directly affects size, weight, joints, and cost. Use standard designations so suppliers quote apples-to-apples and your documentation remains auditable.

- Copper (C110, ASTM B187) — Benchmark conductivity (~100% IACS), excellent joints, higher density. See our detailed comparison: Copper vs. Aluminum Busbar.

- Aluminum (6101, ASTM B317) — Lower mass and price; requires larger cross-section for the same ampacity and careful joint design (surface prep, suitable plating, and pressure).

When joints matter (they always do), specify plating at interfaces: tin is common; silver is used for demanding, high-cycle or high-temperature joints.

Clearance & creepage inside switchboards (IEC 60664-1, UL 891)

Two distances govern insulation coordination:

- Clearance: shortest air distance between live parts (prevents flashover).

- Creepage: distance along an insulating surface (prevents tracking).

Minimum values depend on insulation system, pollution degree, and overvoltage category. In IEC markets, use IEC 60664-1 tables; in North America, UL 891 and NEC Article 408 govern construction/installation details. For design notes, see TI’s concise note on creepage/clearance: SLUP421.

Temperature-rise verification under IEC 61439-1/-2

IEC 61439 modernized type testing into design verification with three permitted methods: test, comparison, or assessment. Temperature-rise limits ensure that busbars, devices, and connections do not exceed allowable over-temperatures under rated load. Many manufacturers verify by test at representative ratings and extend coverage by comparison/assessment (within strict rules). High currents typically demand testing; document ambient assumptions and results.

Learn more: ABB workbook: IEC 61439 in practice and nVent Hoffman guide.

Specifying a switchboard busbar: rating, bracing, plating, insulation

Use this framework when writing your spec or RFQ:

- Rated current and duty (continuous, diversity factor) with the required verification method (IEC: test/comparison/assessment, or UL compliance basis).

- SCCR / AIC target and the available fault current at the installation (drives busbar supports and bracing).

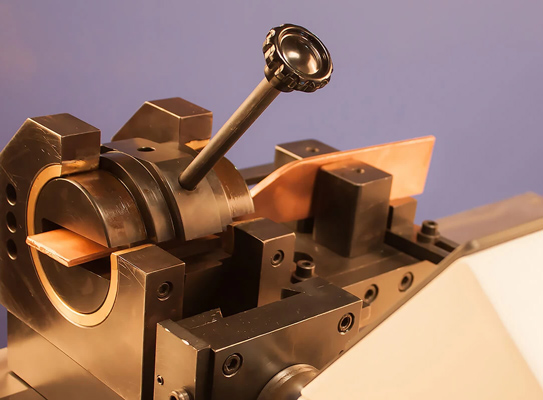

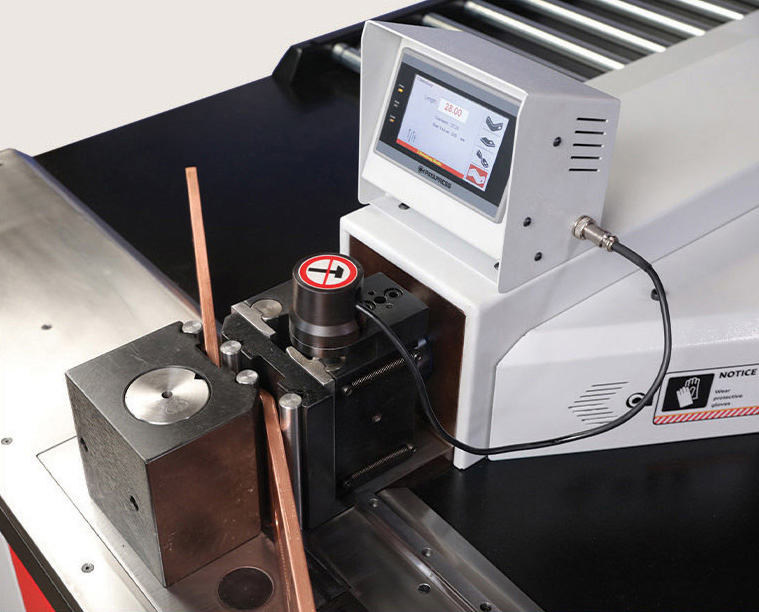

- Material & standard: Cu C110 (ASTM B187) or Al 6101 (ASTM B317); required plating (tin/silver). For fabrication insights, see our production pages: Busbar Bending Machine, Busbar Punching & Cutting Machine, and 3-in-1 Bus Bar Machine.

- Arrangement: single, double, or laminated (sandwich) for compactness and lower inductance. See also: Guide to busbar arrangements.

- Insulation: bare, heat-shrink, or epoxy/insulated bars; specify the creepage/clearance table references you used.

- Assembly & torque: follow the device OEM torque tables; require inspection marks after thermal cycling.

- Compliance regime: IEC 61439-1/-2 (EU/international) or UL 891 + NEC (North America).

When to choose laminated (sandwich) busbars

Laminated busbars reduce loop inductance and can improve thermal performance in compact, high-current, high-harmonic environments. They cost more and need careful interface hardware, but shine where footprint and EMI matter.

Tapping policy and safe connections to busbars (NEC/UL)

Uncontrolled tapping of live busbars is hazardous and typically outside the product’s listing. In North America, follow UL 891 construction and NEC Article 408 installation practices: use listed/approved hardware, lugs, or tap-off provisions intended for the bus.

High-utility selection matrix

The matrix below helps engineers finalize material, arrangement, plating/insulation, and verification approach. Use it during pre-RFQ reviews with stakeholders.

| Use case | Rated current band (A) | Busbar material | Arrangement | Insulation | Plating | Short-circuit target (kA RMS 1s) | Spacing reference | Verification method | Notes |

|---|---|---|---|---|---|---|---|---|---|

| Main LV switchboard (industrial) | 1600–4000 | Cu C110 (ASTM B187) or Al 6101 (ASTM B317) | Single or double stack | Bare or heat-shrink | Tin common; silver at joints | 50–100 | IEC 60664-1 or UL 891 | IEC 61439 test/comparison | Choose material by conductivity vs. mass; confirm supports/bracing. |

| MDB with high harmonic content | 2500–6300 | Cu C110 | Double or laminated | Heat-shrink or epoxy | Tin/silver | 65–100 | As above | Test preferred at high currents | Laminated busbars can lower stray inductance/temperature rise. |

| Commercial distribution board | 800–1600 | Cu or Al 6101 | Single | Bare or heat-shrink | Tin | 25–50 | As above | Assessment/comparison possible ≤1600 A | Verify ambient; derate if >40 °C. |

| Busbar trunking interface | 1000–4000 | Per BTS | Per BTS | Per BTS | Per BTS | Per BTS | IEC 61439-6 | As per BTS | Clarify interface hardware and tap-off ratings with the busway vendor. |

Notes & assumptions: Current bands and kA targets are typical planning categories to drive verification and procurement conversations; final values must be verified by design/testing per IEC 61439-1/-2 or UL 891 and project fault studies. Material standards for RFQs: ASTM B187 (copper C110) and ASTM B317 (aluminum 6101). Sources: ABB (2016), nVent Hoffman (guide); IEC 60664-1 (2020); UL 891 program page (ongoing). All values are indicative and subject to change.

Price/TCO factors

- Material & plating: Cu vs. Al; tin vs. silver joints. (Use commodity-indexed quotes; specify Incoterms.) See material comparison.

- Verification & testing: Type tests or third-party evidence add cost but de-risk compliance (IEC 61439 design verification).

- Environment: Elevated ambient or corrosive atmospheres may drive insulation, plating, and derating—impacting lifetime costs.

- Integration: Interfaces to busbar trunking (IEC 61439-6), metering, and monitoring equipment add cost/benefit.

RFQ checklist

- Standards regime: IEC 61439-1/-2 or UL 891 + NEC 408

- Rated voltage/frequency; rated current per section

- Available fault current (kA RMS, 1s) and target SCCR

- Busbar material/standard (C110/ASTM B187 or 6101/ASTM B317), arrangement (single/double/laminated)

- Plating (none/tin/silver) and insulation (bare/heat-shrink/epoxy/insulated bar)

- Creepage/clearance basis (IEC 60664-1 table refs or UL 891 rules)

- Verification method (test/comparison/assessment) and ambient assumptions

- Interface to busbar trunking (yes/no; rating) and metering/monitoring

- Required documentation: design verification summary, routine test report, torque table, as-built drawings

Where to go next

Ready to move forward? Review material/arrangement options and how they affect manufacturability, then share your RFQ. If you need help selecting a machine for in-house fabrication, explore:

- Busbar Bending Machine (production features)

- Busbar Punching & Cutting Machine

- 3-in-1 Bus Bar Machine (punch-cut-bend)

- Busbar Bender Machine (capacity & options)

Tip: For layout ideas, see our busbar arrangement guide. For fabrication best practices, start with bending techniques.

References & further reading

- ABB — The IEC 61439 standard in practice (workbook)

- nVent Hoffman — IEC 61439 overview

- UL — UL 891: Switchboards (program page)

- IEC — IEC 60664-1: Insulation coordination

- Texas Instruments — Demystifying clearance & creepage (app note)

- Payapress — Copper vs. Aluminum Busbar

Summary: Switchboard busbars are simple in appearance but governed by exacting standards. Lead with the applicable regime (IEC or UL), select material and arrangement for your current and fault duties, and lock in spacing and temperature-rise verification early. Use the matrix and RFQ checklist above to brief suppliers and avoid redesigns later.

Next step: Share your spec and request an indicative quote—or explore 3-in-1 busbar processing for in-house production.

::contentReference[oaicite:0]{index=0}