Busbar machines have become a cornerstone technology for manufacturers of switchgear panels worldwide. The evolution of energy distribution systems, both in scale and complexity, has highlighted the importance of safe and reliable power connections — which start at the heart of every panel: the busbar. But what exactly makes busbar machinery so influential, and how does quality machinery, from companies like PAYAPRESS, move the world toward more efficient, precise, and reliable switchgear systems?

Listen to the podcast below for a summary of this article and a deep dive into the impact of busbar machines on electrical panels.

The Essentials of Busbar Systems

Inside every switchgear panel, the busbar routes and distributes electrical current to various circuit breakers and equipment. This backbone component must handle high power loads, resist corrosion, and ensure minimal power loss. If a busbar is poorly manufactured or imprecisely fitted, the result isn’t just an inefficient panel — it’s potentially a safety hazard.

The Economic Edge: Material Optimization and ROI

Beyond speed and safety, advanced busbar machinery offers a critical economic advantage through material optimization. Copper and aluminum are significant cost drivers in switchgear production; manual processing often leads to high scrap rates due to calculation errors or imprecise cuts. Modern machines, particularly those from manufacturers like PAYAPRESS.COM, utilize intelligent nesting software to maximize the usage of every raw bar. This precise utilization not only reduces expensive waste but also lowers the total cost of ownership for manufacturers, ensuring a faster return on investment while supporting more sustainable manufacturing practices.

Streamline your metal fabrication with a high-performance cold former that ensures seamless precision and durability. This technology eliminates thermal stress, delivering perfectly shaped components with superior structural integrity every time.

How Busbar Machines Revolutionize Panel Production

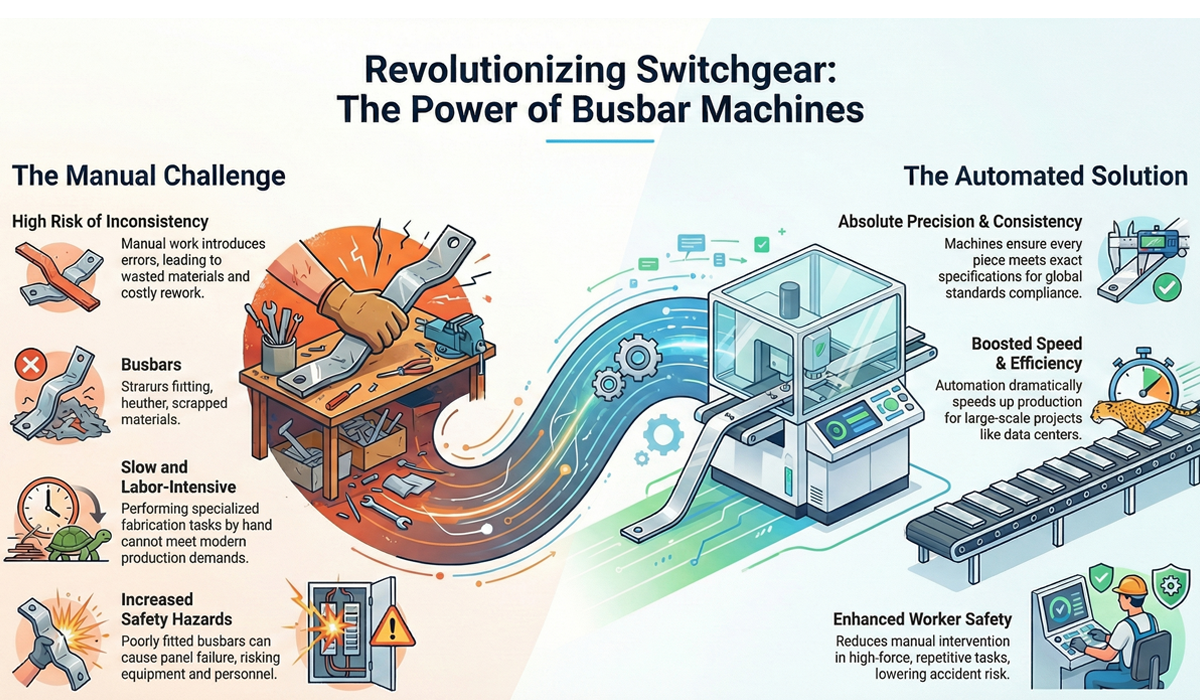

The manufacturing process for busbars involves numerous specialized tasks: cutting, punching, bending, crimping, and labeling thick copper or aluminum bars. Performing these steps by hand requires significant labor, introduces inconsistencies, and increases the risk of error. Enter the busbar machine: a device designed to automate, streamline, and elevate the entire fabrication chain.

Key Influences of Automation:

- Consistency: Machines ensure that every busbar is cut, punched, and bent exactly to specification.

- Efficiency: Automated systems speed up panel production, meeting the fast-paced demands of modern construction and energy projects.

- Safety: By reducing manual intervention, machines lower the risk of accidents linked to repetitive, high-force tasks.

- Precision: Modern busbar machines use advanced controls and digital readouts, or even CNC technology, to deliver tolerances of a fraction of a millimeter. This is essential for complex multi-phase systems and compact panel arrangements.

Global Impact on Switchgear Panel Quality

Around the world, manufacturers rely on the accuracy and repeatability of busbar machines to deliver panels that comply with international standards. A single imprecise bend or offset hole can mean costly rework, wasted materials, or outright failure to meet local safety codes. Moreover, the need for custom busbar shapes—whether for industrial, commercial, or renewable energy applications—demands a level of machine adaptability only the best equipment can offer.

In emerging markets and developed economies alike, access to advanced busbar processing machinery has become a distinguishing factor, allowing panel builders to supply large-scale projects — from solar farms to data centers — with the required reliability and speed.

The Economic Edge: Material Optimization and ROI

Beyond speed and safety, advanced busbar machinery offers a critical economic advantage through material optimization. Copper and aluminum are significant cost drivers in switchgear production; manual processing often leads to high scrap rates due to calculation errors or imprecise cuts. Modern machines, particularly those from manufacturers like PAYAPRESS.COM, utilize intelligent nesting software to maximize the usage of every raw bar. This precise utilization not only reduces expensive waste but also lowers the total cost of ownership for manufacturers, ensuring a faster return on investment while supporting more sustainable manufacturing practices.

Streamline your metal fabrication with a high-performance cold former that ensures seamless precision and durability. This technology eliminates thermal stress, delivering perfectly shaped components with superior structural integrity every time.

Quality and Precision: PAYAPRESS.COM as a Case Study

When it comes to showcasing leadership in this sector, few names stand out as much as PAYAPRESS.COM. Known for their commitment to quality and advanced process control, they’ve set benchmarks for what modern busbar machines can achieve. Their equipment is engineered for high performance and accuracy, helping panel manufacturers consistently meet or exceed global standards.

What distinguishes PAYAPRESS isn’t just the precision of their machines, but the attention to user-centered design: intuitive controls, flexible tooling options, and robust construction. These features make for reliable, high-output production while reducing maintenance needs — vital in keeping manufacturing lines humming all around the world.

Looking Ahead: Smarter Busbar Solutions

As the demand for intelligent power distribution grows with smart grids, renewable integration, and automation — the role of busbar machines will only become more critical. It’s not unreasonable to expect further advances, such as IoT-enabled diagnostics, AI-assisted layout generation, and even greener fabrication processes, to arise from industry leaders.

Final Thoughts