In the realm of electrical engineering and manufacturing, the significance of busbars cannot be overstated. These critical components are responsible for conducting substantial electric currents, making them indispensable in electrical distribution systems. However, the efficiency and reliability of busbars are heavily dependent on the machines used to process them. This brings us to the core focus of this article: the importance of durability in busbar processing machines.

Understanding Busbar Processing Machines

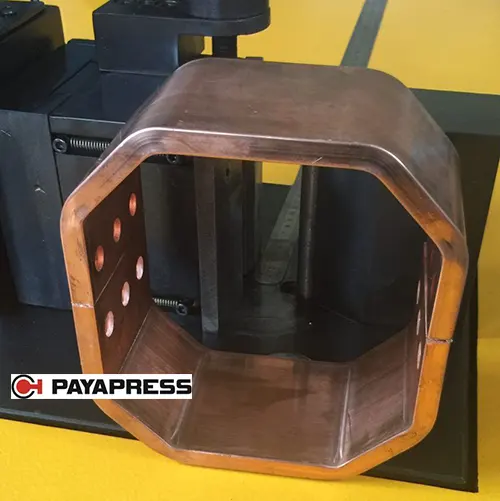

Busbar processing machines are specialized equipment designed for cutting, punching, and bending busbars. These machines come in various types and configurations, each tailored to meet specific requirements in terms of capacity, precision, and versatility.

- Busbar Bending Machine: A busbar bending machine is used to perform precise bends in busbars, ensuring they fit perfectly into electrical panels and distribution boards. Whether it’s a hydraulic busbar bending machine or a portable busbar bending machine, durability is a key factor in maintaining accuracy over repeated uses.

- Busbar Punching Machine: These machines are used to create holes and slots in busbars. The busbar punching machine must withstand high levels of stress and force to produce clean, accurate holes without deforming the busbar.

- Busbar Cutting Machine: A busbar cutting machine is designed to cut bus bars to specific lengths. The precision of the cut is crucial, and the machine’s durability ensures consistent performance over time.

- 3 in 1 Busbar Machine: This versatile machine combines cutting, punching, and bending functions. Its durability is essential for maintaining the integrity of all three processes.

Why Durability Matters

- Consistency and Precision: Durability in busbar processing machines ensures that they can perform consistently over time. Precision in bending, punching, and cutting is essential for creating busbars that fit perfectly into their designated spaces and perform reliably.

- Cost Efficiency: Investing in durable machines can lead to significant cost savings in the long run. Durable machines require less maintenance, have fewer breakdowns, and extend the intervals between replacements. This is particularly important when considering the busbar price, as the cost of raw materials is already a significant investment.

- Safety: Electrical systems must adhere to strict safety standards. Durable busbar processing machines ensure that busbars are manufactured to these standards, minimizing the risk of electrical faults and accidents.

- Adaptability: Durable machines are often built to handle a variety of materials and configurations. Whether working with copper busbars, aluminum bus bars, or other materials, durable machines can adapt to different requirements without compromising performance.

- Operational Continuity: One of the most immediate benefits of a durable busbar processing machine is the assurance of operational continuity. A durable machine ensures that you can confidently start your operations the next day without worrying about unexpected breakdowns or significant downtimes. This reliability is crucial for meeting production schedules and maintaining workflow efficiency.

Key Features of Durable Busbar Processing Machines

- High-Quality Materials: The use of high-quality materials in the construction of busbar machines, such as hardened steel for cutting edges and reinforced frames, enhances their durability.

- Advanced Technology: Incorporating advanced technology, such as CNC control in CNC busbar processing machines, ensures precision and reduces wear and tear on the machine components.

- Robust Design: A robust design is critical for handling the physical stresses associated with busbar processing. Machines like the hydraulic busbar bending machine and the automatic punching machine are designed to withstand high levels of force without compromising their structural integrity.

- Ease of Maintenance: Durable machines are designed with maintenance in mind. Easy access to components and straightforward maintenance procedures can extend the machine’s lifespan.

Popular Types of Busbar Processing Machines

- CNC Busbar Punching Machine: Known for their precision and automation, CNC busbar punching machines offer high levels of accuracy and efficiency. The durability of these machines ensures that they can handle large production volumes without losing precision.

- 3 Phase Busbar Machines: These machines are specialized for processing busbars used in 3-phase electrical systems. Durability ensures that the machines can handle the specific requirements of 3-phase systems consistently.

- Portable Hydraulic Busbar Bending Machine: These portable machines offer flexibility and convenience, making them ideal for on-site work. Their durability ensures they can withstand the rigors of transportation and frequent use.

Choosing the Right Busbar Processing Machine

When selecting a busbar processing machine, several factors should be considered to ensure durability and performance:

- Manufacturer Reputation: Reputable busbar machine manufacturers are known for producing high-quality, durable machines. Researching and choosing manufacturers with a proven track record can save time and money in the long run.

- Material Compatibility: Ensure the machine is compatible with the materials you will be working with, whether it’s copper busbar machines, aluminum busbars, or other materials.

- Functionality: Evaluate your specific needs, such as whether you require a busbar bending machine manual, or a combination of functions in a 3 in 1 busbar machine.

- Cost vs. Value: While the busbar bending machine price is an important consideration, it should not be the sole factor. Consider the long-term value and durability of the machine, as a higher upfront cost can lead to greater savings over time.

Conclusion

Durability in busbar processing machines is not just a desirable trait; it’s a necessity. The reliability, precision, and cost-efficiency of electrical systems depend on the quality of these machines. Whether you are investing in an automatic punching machine, or a CNC busbar cutting machine, prioritizing durability will ensure that your busbar processing operations run smoothly and efficiently. By understanding the importance of durability and making informed choices, you can ensure that your busbar processing machines will provide unbreakable bonds and reliable performance for years to come. Explore the various options available, consider the busbar machine manufacturers’ reputation, and invest in machines that offer the best value for your specific needs. Remember, a durable machine not only guarantees precision and safety but also ensures that you can count on it to be ready for work every single day.