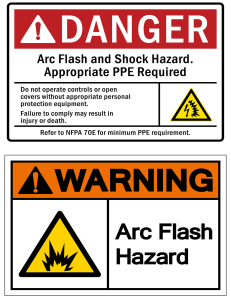

NFPA 70E Label Requirements (130.5(H))

- Nominal system voltage

- Arc‐flash boundary (distance to 1.2 cal/cm²)

- Only one PPE approach on one label: (a) available incident energy with the working distance, or (b) PPE category from tables, or (c) minimum arc rating of clothing, or (d) site‐specific PPE level

DO NOT have both PPE category and incident energy on one tag. The tag must be durable to the environment (chemicals, heat, UV).

ANSI Z535 format guidelines

Use signal words to convey alert level:

WARNING (orange): Indicates a serious hazard.

DANGER (red): Indicates the most serious hazards.

- Be straight‐forward and specific; use professional heavy duty tags.

NEC 110.16(B) – 2023 Additions (Installation Tagging)

- Permanent arc‐flash marking required on service equipment and feeder‐supplied equipment rated ≥ 1000 A (was 1200 A).

- Label must be in accordance with good industry practice (NFPA 70E) and meet NEC 110.21(B) durability standards.

Service vs. Feeder Labels

- Both service equipment and feeder-supplied gear (≥ 1000 A) require labels.

- Place labels on the exterior of panelboards, switchboards/switchgear, MCCs, and industrial control panels.

IEEE 1584 Calculations (Incident Energy Method)

Many facilities use IEEE 1584‑2018 to calculate incident energy and arc‑flash boundary.

Working distance is significant (Typical values: 18 in for LV panels/MCCs; 24 in for LV switchgear; 36 in for MV). Inputs can be short‑circuit current, protective device clearing time, enclosure/equipment class, and electrode configuration.

Arc-Flash Boundary (definition)

Arc-flash boundary is defined as the distance where incident energy equals 1.2 cal/cm² (the boundary of a second-degree burn).

It varies by equipment and calculation. Some facilities use a conservative standard value (e.g., 8–10 ft) for simplicity, but actual IEEE 1584 calculations for many LV panels often yield smaller distances (≈ 0.9–1.5 m / 3–5 ft)—verify by study.

Related Table — PPE Method Selection (NFPA 70E)

| Method | What Appears on Label | Pros | Considerations |

| Incident Energy Method | Incident energy (cal/cm²) at a stated working distance | Equipment‑specific; reflects actual device settings; generally preferred in modern programs | Requires study and periodic updates; results change if upstream system or protection changes |

| PPE Category Method | NFPA 70E PPE Category (1–4) and task description | Simpler when table limits are satisfied; no detailed study needed | Not equipment‑specific; must verify fault current and clearing time stay within table limits |

| Minimum Arc Rating | Minimum arc rating of clothing (cal/cm²) | Simple to communicate a floor for PPE | May be overly conservative or not reflect specific equipment tasks |

| Site‑Specific PPE Level | Defined site PPE level (e.g., Level 2) | Easy for internal consistency | Still needs engineering basis; keep mapping to arc ratings clear |

PPE Categories (NFPA 70E Tables)

NFPA 70E defines PPE Categories 1–4 for specified tasks/limits. Use either the Incident Energy Method or the PPE Category Method—not both on the same label. In practice, the incident‑energy method is now preferred in many facilities because it is equipment‑specific.

Label Placement & Durability

- Place labels where qualified persons can see them before any work (door exterior).

- Use materials that resist UV, chemicals, and heat (thermal‑transfer or engraved industrial labels are common).

Update Frequency & Triggers

- Review interval: at least every 5 years to confirm data supporting the label is still accurate; document the review.

- Update sooner after system changes, especially upstream: utility transformer size/impedance changes, feeder/source reconfiguration, protective device type/setting changes, new equipment, or after a fault event.

Maintenance Mode Reduction (how it’s implemented)

Energy‑reducing maintenance switching temporarily forces instantaneous or very fast tripping to reduce arcing duration during specific tasks. It is commonly provided via a circuit breaker maintenance switch/setting or a protective relay feature; related techniques include Zone Selective Interlocking (ZSI) and active arc‑flash mitigation. Enable only for the job and disable afterward, and capture the status/steps in the energized work permit.

46/200 45 words Standards & Safety (U.S.)

OSHA 29 CFR 1910: OSHA does not require arc-flash equipment labeling, but the NFPA 70E are accepted as industry consensus standards for electrical safety compliance.

• NFPA 70E: The workplace labeling and work practices (130.5/130.5(H))

• NEC (NFPA 70): Marking of installation – 110.16(B) (2023), Durability – 110.21(B).

For authoritative guidance on arc-flash labeling and safe electrical work practices, see NFPA 70E® — Standard for Electrical Safety in the Workplace. This consensus standard (including §130.5(H)) defines required label content, arc-flash boundary determination, and PPE selection, and is widely recognized across industry and safety programs.

FAQ (Short)