Busbar Processing Machine: How to Cut-Punch-Bend Busbar

In many panel shops and factories, a busbar processing machine helps us work faster and safer. It prepares copper busbar and aluminum busbar for our switchgear and control panels. With one flow—cut, punch, bend—we can reduce material handling, keep better quality, and increase throughput. This short guide uses clear words and practical points. It explains what a busbar processing machine does, the main types (manual/portable, hydraulic, CNC busbar machine, and 3 in 1 busbar machine), and how to choose.

What Is a Busbar Processing Machine?

It is a busbar fabrication machine that automates three core operations. We use it after receiving raw bar stock. The machine turns raw bars into ready parts with correct holes, lengths, and angles.

Core Operations: Cutting, Punching, Bending (Single-Setup vs Multi-Station)

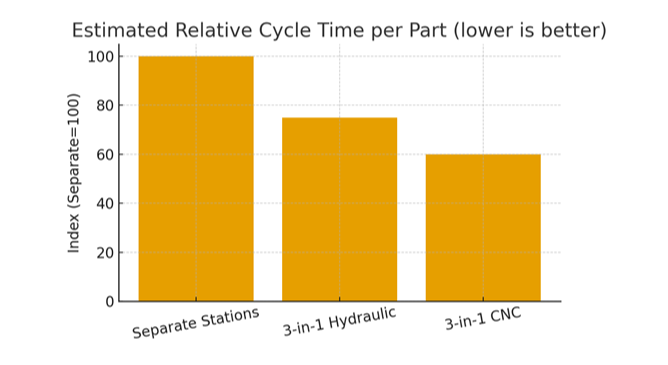

Cutting makes the right length or shape; good shearing keeps edges straight and helps burr control. Punching makes round, oblong, or slot holes with matched die sets; hole-to-edge accuracy is important. Bending forms 90°, U, Z, or offset bends. An integrated workstation (3-in-1) lets us do all in one setup and reduces handling. Separate stations still work, but changeover time and movement are higher.

Where It Fits in the Workflow (material → cut → punch → bend → QA)

The usual flow is simple: feed material, cut to length, punch holes/slots, then bend. After that, do QA: check dimensions, angles, and surface finish, then record the job for traceability.

For reliable and accurate busbar processing solutions, refer to standards from reputable organizations like the International Electrotechnical Commission (IEC), which defines industry guidelines for busbar processing and electrical panel assembly.

PLC Control vs CNC (Offline Programming & Traceability)

PLC (Programmable Logic Controller) control is common and reliable. A CNC busbar machine adds CAD/CAM, HMI touch screen, and offline programming. You can prepare parts in office, use nesting to save material, and capture production data for MES/ERP. CNC also helps repeatability with servo positioning and angle-measurement sensors.

Types & Configurations

Manual/Portable

Portable units are light and useful on site for installation or service. They can punch, bend, and cut with basic dies. The limits are lower capacity and slower throughput.

Hydraulic Stations

A hydraulic busbar machine gives strong force and fast cycles. It is good for heavy-duty work and thicker bars. Many 3-in-1 lines use hydraulic power for punching, shearing, and bending.

CNC Busbar Machine

Computer control improves accuracy and repeatability. Servo drives, backgauges/stops, laser positioning, and angle sensors (often ±0.5°) reduce rework. Offline programming and libraries speed up changeover.

3-in-1 / Integrated Line

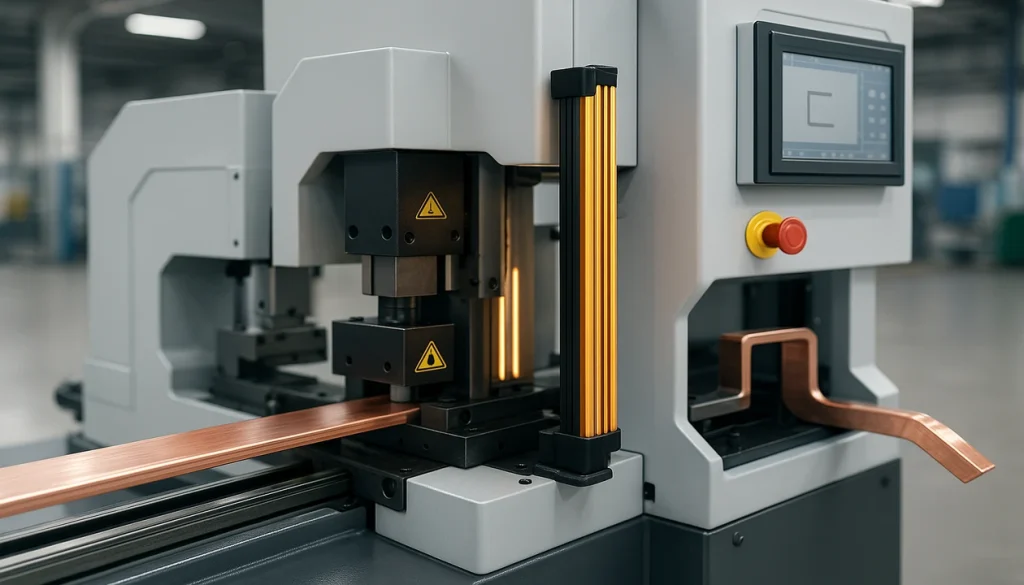

A 3 in 1 busbar machine combines cut-punch-bend. It reduces floor moves and handling risk, and it is easier to keep alignment and quality stable. Foot pedals and safety light curtains are common for safe work.

Mid-Article Chart: Throughput Comparison

The chart below is an illustrative comparison. Actual results depend on your part mix, tooling, and operator skill.

Quality & Precision for Copper/Aluminum

Hole-to-Edge, Burr Control, Deburring & Edge Finish

Keep correct die clearance to control burrs. After cutting or punching, do quick deburring so the edge is safe and the electrical contact stays good.

Mark-Free Bending, Minimum Bend Radius, Angle Measurement

Use pressure plates or proper tooling to avoid marks. Follow minimum bend radius so the bar does not crack. Use angle-measurement or encoder systems to keep bends within tolerance.

QA Checkpoints & Documentation (Traceability)

Set simple checkpoints for sizes, angles, and surface. Record job ID, operator, tooling, and program revision. This helps later audits and reduces mistakes.

Throughput & Footprint

Cycle-Time & Changeover (Quick-Change Tooling, Nesting)

Quick-change cassettes and die libraries reduce setup time. Nesting in software can cut scrap and speed production.

Space/Energy & Staffing vs Stand-Alone Cells

An integrated workstation saves floor space and may use energy more efficiently per part. One trained operator can handle more work compared to three separate machines.

Safety And Ergonomics (Interlocks, Light Curtains, Handling Risk)

Use interlocks, light curtains, and clear emergency stop button. Plan safe lifting/feeding to reduce handling risk and fatigue.

Cost, TCO & ROI

CapEx is the purchase price. OpEx is tooling, training, maintenance, and spare parts. A good busbar processing machine can pay back by saving labor, lowering scrap and rework, and shortening changeover.

TCO Mini-Table (example)

| Cost Head | What Drives It | How to Control It |

| Tooling & Dies | Hole sizes, materials, wear | Quick-change system; preventive maintenance |

| Labor & Training | Operator skills and setup time | Offline programming; standard work |

| Scrap & Rework | Burrs, angle errors, wrong holes | Nesting; angle sensors; QA checkpoints |

| Downtime | Changeover and unplanned stops | Libraries; spare parts; service SLAs |

Selection Guide (Buyer/RFQ Checklist)

- Capacity & materials: max thickness/width, copper vs aluminum mix.

• Accuracy: punching tolerance, bending precision, surface quality (mark-free).

• Software/connectivity: offline programming, data capture, MES/ERP.

• Safety & service: light curtains, warranty, spare parts, response time.

• Future proof: modular tooling, upgrade paths, clear training plan.

For more information on busbar processing technology and its applications, you can refer to the International Electrotechnical Commission (IEC), a globally recognized source for technical standards in the electrical industry.

Frequently Asked Questions

CNC vs. hydraulic—how do I choose?

Hydraulic delivers high force and high speed for heavy bars. A CNC busbar machine delivers improved accuracy, repeatability, and offline programming. Choose CNC for complex work and fast changeovers; choose hydraulic for brute force.

What is normal accuracy?

Punching tolerance of about ±0.2 mm is achievable with proper tooling. Bending accuracy of about ±1°, with repeatability normally ±0.5° or better.

Are copper and aluminum settings different?

Yes. Material properties are different. Adjust die clearance and bending parameters by metal.

Can a 3-in-1 replacement replace separate stations?

Typically yes. It reduces handling, conserves floor space, and keeps alignment stable. Very high-volume lines still might streamline stations for speed.

What should I expect in a service/warranty agreement?

Clear warranty term, spare-parts schedule, training regimen, and service call response time (SLA).