IP vs NEMA Ratings & IK — A Practical Engineer’s Guide

IP vs NEMA — what’s different?

- IP “Ingress Protection, IEC 60529”: Two digits. First is solids (0–6), second is water (0–9). Example: IP66 = dust‑tight + strong water jets.

• NEMA (NEMA 250): Uses enclosure “Types” such as 3R, 4X, 12. Numbers are not a simple ladder.

Core idea: IP covers only ingress (dust/water). NEMA adds real‑world extras like ice and corrosion (4X).

What each standard covers

- IP: ingress of dust and water.

• NEMA: ingress + corrosion/ice; some Types for special atmospheres.

• IK: impact resistance in Joules for vandal or industrial risk areas.

NEMA-to-IP mapping (approximate)

No Exact 1:1 Match.Use this table only as a quick starting point:

| NEMA Type | Short description | Approx. IP |

| 1 | Indoor; falling dirt | IP10 |

| 3R | Outdoor rain/sleet; ice | IP14–IP64 |

| 4 / 4X | Hose water; dust; ice; 4X = corrosion‑resistant | IP65–IP66 |

| 6 / 6P | Temporary/prolonged submersion | IP67–IP68 |

| 12 / 12K | Indoor; dust, dripping/splashing; oil/coolant | ≈ IP52 |

NEMA 4X vs IP66 (washdown)

IP66 = dust‑tight + strong jets. NEMA 4X = hose water + dust + ice + corrosion resistance. If chemicals or salt are present, 4X is usually safer.

IP55 vs NEMA 12 (indoor)

NEMA 12 covers dust, lint, droplets, and oils/coolants. IP55 allows low‑pressure jets. NEMA 12 is closer to IP52 than IP55.

NEMA 3R vs IP54 (basic outdoor rain)

NEMA 3R focuses on rain/sleet/snow with ice resistance. IP54 is dust‑protected + spray.

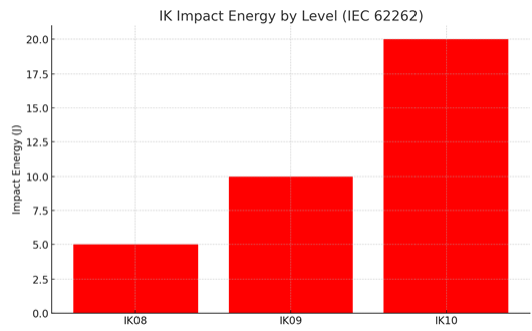

IK impact rating — simple view

IK shows how much impact energy the enclosure can take. For public areas or tough plants, aim for at least IK08.

Figure: Red bars show impact energy by IK level (higher Joules = stronger).

| IK level | Impact (J) | Example test (mass × height) |

| IK08 | 5 | ≈1.7 kg × 0.3 m |

| IK09 | 10 | ≈5 kg × 0.2 m |

| IK10 | 20 | ≈5 kg × 0.4 m |

IP69K vs NEMA 4X (high‑pressure cleaning)

IP69K handles very hot (≈80°C), high‑pressure jets. NEMA 4X covers hose‑down plus corrosion. In food/beverage and CIP/SIP areas, check both the rating and the material (e.g., 316L stainless steel).

Seals, glands, and materials matter

Your rating is only as strong as the weakest opening.Use cable glands with equal or higher IP/NEMA rating, seal unused knockouts, and torque correctly. For coastal or chemical exposure, choose 316L stainless steel or quality polycarbonate and consider NEMA 4X+IP66.

Regional practice: US vs EU

North America usually specifies NEMA Types; Europe and much of Asia use IP + IK. Many products offer dual‑marking (e.g., NEMA 4X / IP66) for easy procurement.

Quick FAQ

Is NEMA 12 waterproof?

No. It is for indoor dust/light splash and oils; not jets or submersion.

What IP equals NEMA 12?

About IP52.

IS NEMA 4 the same as IP66?

Not exactly. IP66 is jets; NEMA 4 adds ice; 4X adds corrosion resistance.

What IK do I need?

Public/industrial risk often starts at IK08; IK10 is very robust (20 J).

IP67 vs IP68?

Both allow immersion. IP68 is deeper/longer, agreed between maker and tester.

Authoritative source:

For the official definitions of enclosure types and how they differ from IP ratings, see NEMA Enclosure Types (NEMA)

Note: there is no exact 1:1 mapping between NEMA and IP—each covers different test scopes and conditions.

Meta focus: IP vs NEMA, IP rating chart, NEMA enclosure types, IK rating chart, NEMA 4X vs IP66.