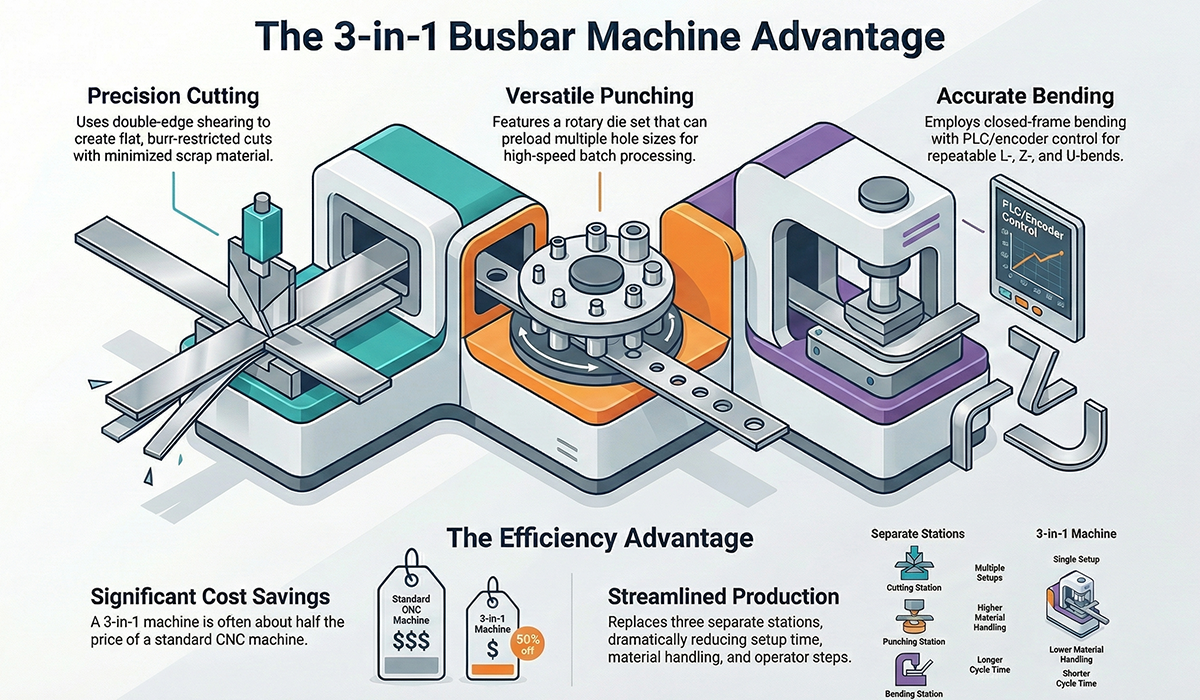

A busbar machine is an essential tool in the production of electrical systems, capable of cutting, bending, and punching busbars efficiently. By integrating all these functions into one unit, a 3-in-1 busbar bending machine offers a cost-effective solution, reducing the need for multiple machines and minimizing handling. This approach not only speeds up production but also lowers overall maintenance costs. Whether you are working with copper busbars or aluminum busbars, this machine is designed to streamline processes for high-current distribution equipment and control panels.

Prefer listening? You can play the audio version of the rest of this article below.

Why run three separate machines when one integrated system can cut, punch, and bend in a single setup? Reduce handling, speed throughput, and lower total cost of ownership.

- 3-in-1 machines can cut, bend, and punch busbars simultaneously in a single compact unit.

- Commonly used for C110 copper and 6101-T6 aluminum busbars (including copper–aluminum compound bars) in high-current distribution equipment and industrial control panels.

- They are cost-effective, often about half of the price of a normal CNC machine.

Core Operations Explained

Cutting

The majority of units use double-edge offset shearing with a double-column shear frame to make flat, burr-restricted cuts with minimized scrap. Mechanical stops and scales (or a programmable backstop) aid operators in the replication of lengths.

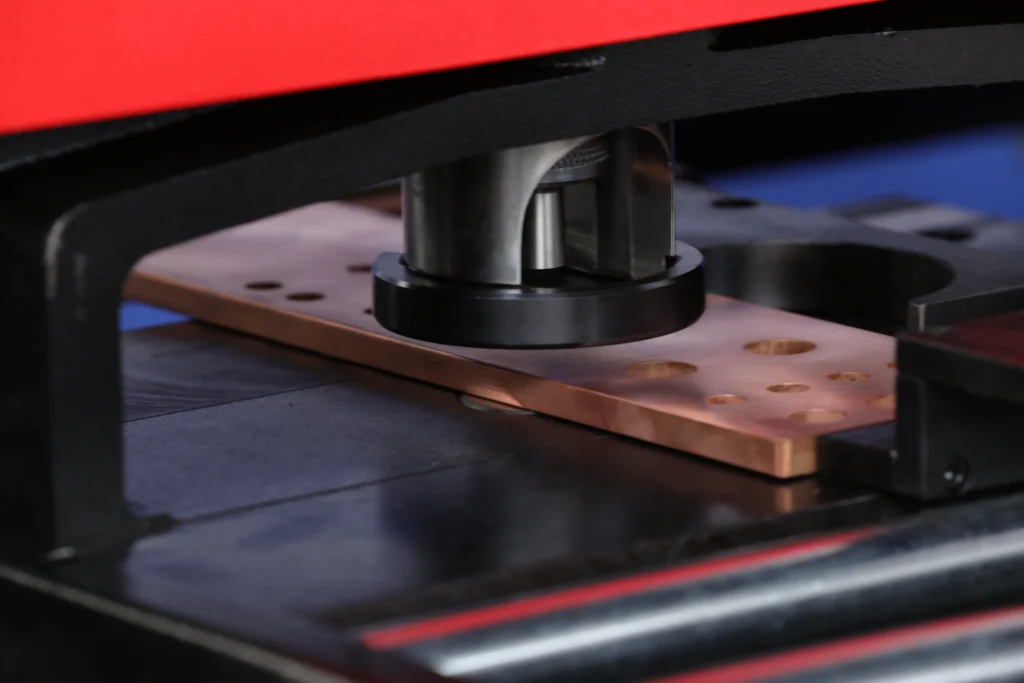

Punching

An independent rotary die set can preload multiple punching dies (e.g., various hole diameters), CNC-machined for concentricity. Two-way mechanical positioning (X/Y) allows for precision hole placement and high batch processing.

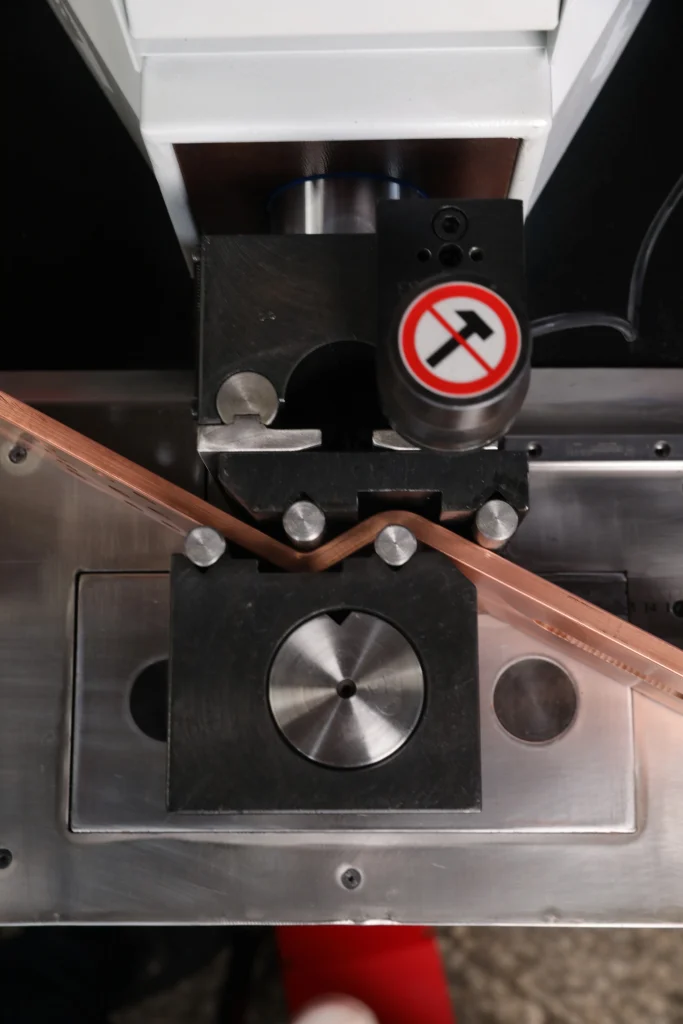

Bending

Closed-fr

ame bending with angle control through a PLC/encoder offers good verticality and repeatable angles. L-, Z-, and U-bends are typical; springback compensation and recommendations for bend radii help maintain accuracy.

Maintenance Differences

CNC models and hydraulic models require daily care such as cleaning the work area, lubricating spare parts, and checking hydraulic oil levels. In CNC models, you may also need to check encoder calibration and back up control parameters.

Bend Radius Guide

Minimum bend radius depends on alloy and thickness. You should use vendor guidelines to prevent surface cracking and springback. Some models like PAYAPRESS machines mitigate springback issues because the encoder is programmed to perform the bending process in two steps.

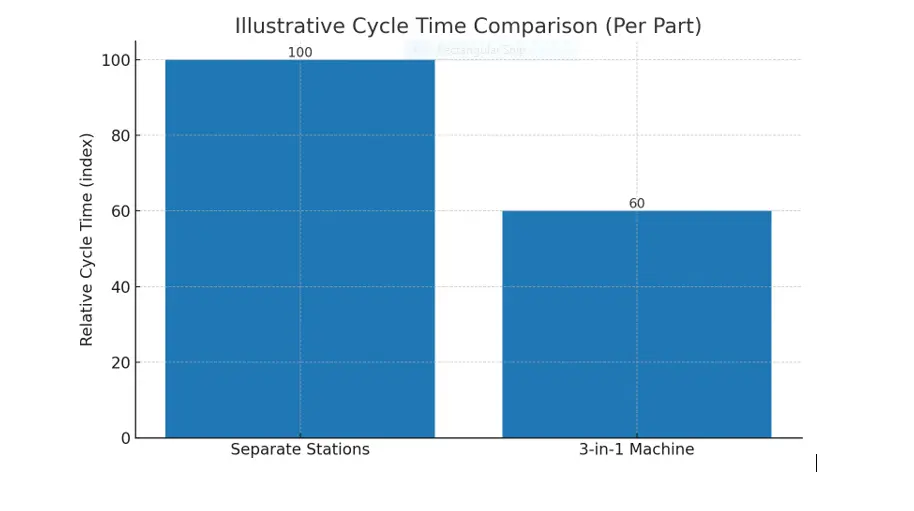

Cycle-Time Comparison (Separate Stations vs. 3-in-1)

The chart below shows a comparison between separate-station machines and 3-in-1 machines regarding cycle time per part.

| Factor | Separate Stations | 3-in-1 Machine |

|---|---|---|

| Setups per part | Multiple | Single |

| Material handling | Higher | Lower |

| Operator steps | More | Fewer |

| Typical cycle time per part | Longer | Shorter |

Reporting & Resource Optimization

Industry 4.0 goes beyond automated machinery. This technology ensures that every piece produced meets stringent quality standards while minimizing material waste. It also enables real-time adjustments based on data analysis. This data-driven approach optimizes material usage, reduces energy consumption, and minimizes waste generation.

What Is the Punching Tonnage and Maximum Die Size?

It depends on materials, thickness, hole perimeter, and other parameters. To choose suitable and demanding die sizes, follow the manufacturer’s charts and guidelines, because different companies may use different naming, parameters, or standards.

One point I would like to mention is that if you have materials for your activities and use various sheet metals, you should consider using the Corner Former machine.

Standards & Safety

Although busbar manufacturing equipment is typically evaluated to machine safety standards, your end assemblies must meet electrical product standards and codes. For North American installations, buyers often cross-reference IEC 61439 concepts with U.S. systems such as UL 891 (switchboards), NEMA PB 2, and NFPA 70 (NEC). Fit, finish, hole quality, and bend accuracy are key workmanship considerations.

Conclusion:

Incorporating a 3-in-1 busbar machine in your production line enhances efficiency, reduces material waste, and cuts down on operational costs. With its ability to handle copper busbar bending, punching, and cutting in a single setup, it delivers precision and consistency. By embracing such integrated solutions, manufacturers can improve throughput while maintaining high-quality standards and reducing the total cost of ownership.