In today’s highly competitive manufacturing world, the need for speed, precision, and efficiency has never been greater. Industries are constantly evolving, and businesses must adapt by incorporating innovative solutions that enhance their production processes. One such solution is the corner forming machine, also known as the cold former. These machines are pivotal in sheet metal fabrication, offering manufacturers the ability to automate processes that were traditionally done manually, saving both time and money while improving precision. If you’re in the business of sheet metal processing, investing in a corner forming machine can significantly elevate your operations.

But what drives the pricing of these machines, and why is it such a valuable addition to your production line? This blog will take you through the pricing structure of corner forming machines, highlighting their value in industrial applications and exploring why they are an essential investment for employers looking to stay ahead of the curve in today’s demanding manufacturing environment.

What Makes Corner Forming Machines a Smart Investment?

Corner forming machines have become a cornerstone in industries like electrical panel manufacturing, automotive production, and HVAC systems. They offer several significant benefits, from automating the corner forming process to drastically improving the quality and speed of production. But what sets these machines apart, and why should manufacturers consider adding them to their operations?

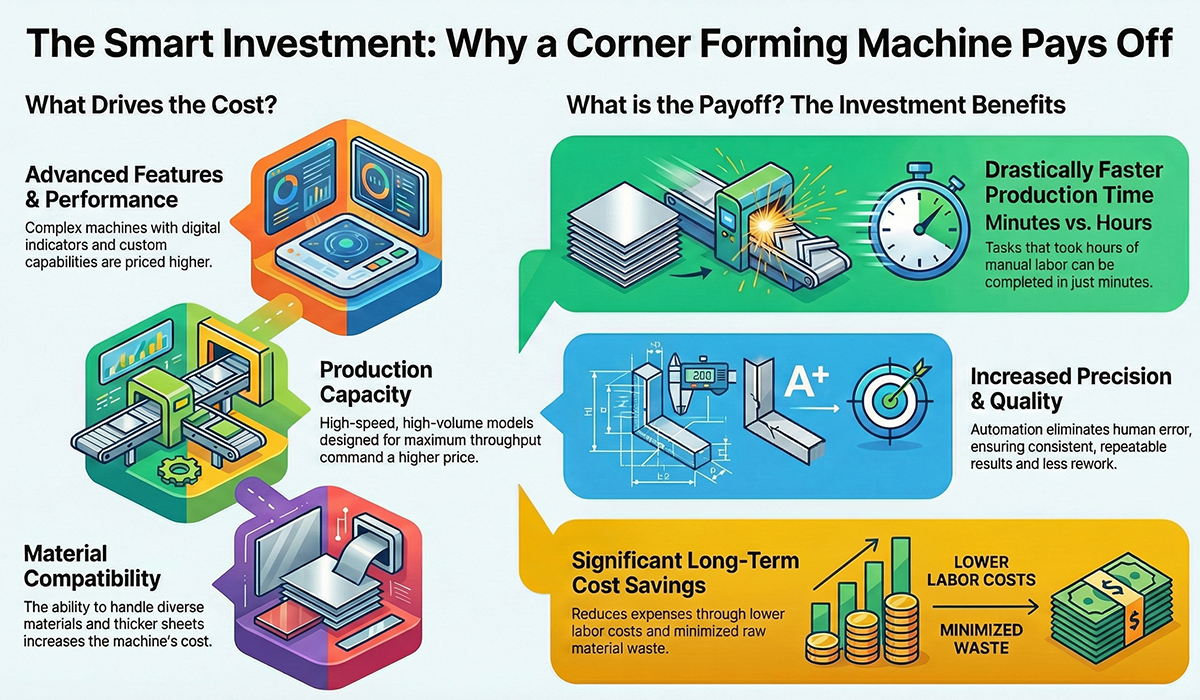

The price of corner forming machines can vary based on several factors, and understanding these can help you make a more informed decision about the investment. Here’s a breakdown of the pricing structure and the value these machines offer:

The Price of Corner Forming Machines

The price of corner forming machines depends on multiple elements that reflect the machine’s capabilities. While it can seem like a significant initial investment, the long-term benefits often outweigh the costs.

Factors Influencing Price:

Machine Features and Performance:

The complexity of the machine plays a significant role in its price. Machines that offer advanced features, such as the CFCM-30ES, which includes digital angle indicators and elastic return compensation, tend to be priced higher. These features allow for more intricate and customized corner formations, making them ideal for high-precision tasks.Production Capacity:

The CFCM-30EH, designed for high-speed, high-volume production, offers multiple power packs to ensure that all stations (bending, punching, cutting) operate simultaneously. The increased production capacity of this model means higher efficiency, which reflects in its pricing.Material Compatibility and Specifications:

Machines designed to handle a wide range of materials, such as aluminum,and steel, with different thicknesses and sheet sizes, can come at a higher price point. For example, machines capable of working with thicker sheets or more complex geometries typically cost more due to the engineering involved.Build Quality and Brand Reputation:

High-quality builds, durability, and brand reputation also influence the price. Established brands like Payapress offer machines with a proven track record, ensuring reliability and long-term performance, which adds to the cost.

Typical Pricing Range:

Corner forming machines typically range from a few thousand dollars for entry-level models to tens of thousands of dollars for more advanced, customizable versions. The CFCM-30EH and CFCM-30ES fall within this price range but offer different benefits based on production needs.

Why Corner Forming Machines Are Worth the Investment

Investing in a corner forming machine, particularly a cold former, can yield substantial returns. Here’s why employers should consider this equipment as a long-term solution for their production lines:

Increased Precision:

Consistent Results: The automation provided by corner forming machines ensures precise and consistent results, eliminating the human error often associated with manual methods. This is critical in industries like electrical panel manufacturing, where precision is key for safety and functionality.

Repeatable Bends: Every part formed is guaranteed to meet the exact specifications, reducing the need for rework and improving product quality.

Faster Production Time:

Time Efficiency: With corner forming machines, what once took hours of manual labor can now be completed in minutes. By automating the bending, punching, and cutting processes, manufacturers significantly speed up production, allowing them to meet higher demand with shorter lead times.

High-Speed Operations: Models like the CFCM-30EH, designed for high-speed production, excel in environments where high throughput is required.

Cost Savings:

Reduced Labor Costs: Corner forming machines minimize the need for manual labor. This leads to a reduction in labor costs, allowing manufacturers to allocate resources to other value-added areas.

Lower Material Waste: The precision of corner forming machines ensures that material wastage is minimized. Accurate cuts and bends result in less scrap metal, saving manufacturers money on raw materials.

Flexibility and Customization:

Ideal for Complex Jobs: The CFCM-30ES, with features like digital angle indicators and elastic return compensation, is perfect for custom jobs that require high precision. Industries that need complex geometries or custom shapes, such as aerospace or high-precision automotive components, benefit greatly from these machines.

Adaptable to Various Industries: Whether you’re working in automotive, aerospace, or HVAC, corner forming machines can be adapted to meet the specific needs of different sectors.

Durability and Long-Term Use:

Investment in Longevity: With proper maintenance, corner forming machines offer long-lasting service, ensuring that businesses get a solid return on investment. Their durability reduces the frequency of replacement and repair costs, adding to the overall value.

Real-World Applications of Corner Forming Machines

Electrical Panel Manufacturing

In electrical panel manufacturing, where precision is crucial, corner forming machines automate the process of forming corners on sheet metal, ensuring structural integrity and consistency.

Automotive Industry

Automotive manufacturers rely on corner forming machines to create metal parts like brackets and reinforcements. These machines guarantee the exact dimensions needed to maintain performance and safety standards.

HVAC and Construction

For HVAC and construction industries, custom metal parts like ducts and structural components need precise corner forming. Corner forming machines ensure the necessary fit and function, improving overall system performance.

Aerospace

In aerospace, precision is paramount. Corner forming machines produce parts that must meet exact tolerances to ensure safety and functionality under extreme conditions.

Why Buy from PayaPress?

At PayaPress, we take pride in offering cutting-edge technology and high-quality manufacturing solutions that cater to the diverse needs of industries worldwide. Our corner forming machines, including the CFCM-30EH and CFCM-30ES, are engineered for reliability, precision, and versatility. By choosing PayaPress, you’re investing in a machine built to streamline your production process while ensuring high-quality results every time. We stand behind our products with exceptional customer service, offering expert guidance to help you choose the right equipment for your business needs. Whether you’re seeking high-speed production or intricate, customized metalworking, PayaPress provides the right solution for enhancing your operational efficiency. Our global presence and commitment to innovation ensure that you receive not only top-tier machinery but also the support necessary to stay competitive in today’s demanding manufacturing landscape.

Conclusion: Investing in Efficiency and Precision

The value of investing in a corner forming machine is clear: it offers increased efficiency, precision, cost savings, and flexibility that will help businesses stay competitive in an ever-evolving manufacturing landscape. Whether you opt for the CFCM-30EH for high-speed production or the CFCM-30ES for more intricate, customized work, corner forming machines will significantly improve the quality and speed of your production line.

In industries where precision and efficiency are key, the decision to invest in a corner forming machine or a cold former will pay off in the long run, helping you meet the growing demands of the market while ensuring product excellence.

Frequently Asked Questions (FAQs)

Frequently Asked Questions (FAQs)

What is the difference between the CFCM-30EH and CFCM-30ES models?

The CFCM-30EH is designed for high-speed, high-volume production, with the ability to process sheet metal up to 120mm x 12mm while operating multiple stations simultaneously. The CFCM-30ES, on the other hand, offers enhanced precision, ideal for intricate designs and custom corner forming. It features digital angle indicators and elastic return compensation for added control and accuracy.

Which materials can be processed with Payapress corner forming machines?

Both the CFCM-30EH and CFCM-30ES models are capable of processing materials such as aluminum, copper, and steel, making them highly versatile for a variety of applications across industries like automotive, HVAC, and electrical panel manufacturing.

What are the key benefits of using a corner forming machine over manual methods?

Corner forming machines offer increased precision, speed, and efficiency compared to manual methods. By automating the process, these machines reduce human error, ensure repeatable results, minimize material waste, and significantly speed up production time.

How much does a corner forming machine cost?

The price of a corner forming machine can vary depending on features and capabilities. Payapress machines like the CFCM-30EH and CFCM-30ES offer competitive pricing based on their high-performance features, including advanced precision control and high-speed production capabilities. The long-term savings from increased efficiency and reduced waste make these machines a smart investment.

What industries benefit from corner forming machines?

Corner forming machines are used across multiple industries, including electrical panel manufacturing, automotive, aerospace, construction, and HVAC. These industries rely on the precision, efficiency, and flexibility that corner forming machines provide for creating custom metal parts and components.