Low-voltage power distribution boards are crucial components in electrical systems, ensuring the efficient and safe distribution of electrical power. These boards come in various designs and are used in a wide range of applications, including substations, industrial facilities, and outdoor environments. With diverse mounting options and configurations, understanding the classification, specifications, installation methods, and safety requirements of these boards is essential for ensuring optimal performance. This guide provides an in-depth look at the different types of power distribution boards, their installation, and essential considerations for busbar sizing and clearances.

Prefer listening? You can play the audio version of the rest of this article below.

Classification of Power Distribution Boards

Power distribution boards are equipment used for controlling and distributing electrical energy.The main power distribution board is typically installed in a substation, connected to the

low-voltage side of the transformer, and is responsible for distributing and controlling the site’s electrical power.

Boards are grouped into three main functional categories:

- Main power distribution board – installed in the substation.

- Sub-main power distribution board – sub-board for facilities / utilities.

- Lighting sub-board – dedicated to lighting circuits.

By installation method they are further classified as:

- Fully enclosed floor-standing (front-accessible, rear-accessible, multi-compartment, multi-box).

- Fully enclosed wall-mounted (flush / surface-mounted).

- Power and lighting distribution boards for outdoor installation.

Further exploration of Power Distribution Systems can be found in the following recommended reading.

| Board Type | Mounting | Access | Typical Application |

|---|---|---|---|

| Main Low-Voltage Distribution Board | Floor-standing | Front or Rear | Substation – primary power distribution |

| Sub-main Distribution Board | Floor-standing | Front or Rear | Facilities / utilities sub-feeds |

| Multi-compartment Board | Floor-standing | Front (each cell) | Motor control centres, expandable systems |

| Multi-box Board | Floor / Wall | Front + Side boxes | Industrial / outdoor dusty or humid areas |

| Sub-distribution Board (wall-mounted) | Wall (flush or surface) | Front | Lighting, sockets, small power circuits |

| Outdoor Power & Lighting Board | Floor (on platform) | Front only | Street lighting, outdoor substations |

Table 1 – Summary of power distribution board types, mounting methods, and typical applications.

Fully Enclosed Floor-Standing Power Distribution Boards

Front-Accessible Board

In this type, all operations — fuse replacement, cable terminations, incoming/outgoing cable connections — are accessible only from the front. A small side door is often provided next to

the main door for feeder cable connections. Cells are divided into top entry and

bottom entry types.

Rear-Accessible Board

Equipment replacement and cable/wire connections are accessible from the rear, while measuring instruments and control operations remain on the front face.

Multi-Compartment Board

Each cell can be divided into three, four, or six main compartments, and each main compartment into two, three, or four sub-compartments. All divisions have standard and equal dimensions,

each section equipped with a separate door for device installation or replacement.

Multi-Box Board

Consists of equal-dimension boxes (cast iron, steel, or hard rubber) that are mechanically connected. Each box has five removable doors. Sealing gaskets on all doors prevent dust and

water ingress. Preferred for outdoor substations in industrial, dusty, or humid areas.

This article serves as a valuable resource for those seeking detailed information on Distribution board.

Maximum Dimensions – Main Low-Voltage Floor-Standing Boards

| Dimension | Front-Accessible (cm) | Rear-Accessible (cm) |

|---|---|---|

| Height | 220 | 220 |

| Width | 90 | 90 |

| Depth | 60 | 80 |

Table 2 – Maximum enclosure dimensions for main low-voltage floor-standing boards.

Dimensions – Main Low-Voltage Multi-Compartment Board

| Height (cm) | Width (cm) | Depth (cm) |

|---|---|---|

| 200 | 50 | 50 |

Table 3 – Standard dimensions for floor-standing multi-compartment boards.

Minimum Clearances Between Metal Electrical Boards and Walls

A suitable distance between the wall and the electrical board, and between two adjacent boards, must always be maintained. The minimum is 70 cm. The clear space in front of

the board door must allow the door to open to at least 90°.

| Board 2 / Board 1 | Front Face (operational) | Face (serviceable) | Rear Face (closed) | Wall |

|---|---|---|---|---|

| Front Face (operational) | 1.2 m | 1.2 m | 1.0 m | 1.0 m |

| Face (serviceable) | 1.2 m | 1.0 m | 0.8 m | 0.8 m |

| Rear Face (closed) | 1.0 m | 0.8 m | 0 m | 0 m |

Table 4 – Minimum distances between same-voltage metal electrical boards and from the wall.

Installation Methods for Floor-Standing Boards

Floor-standing boards may be installed using one of two methods:

A) Installation on a Cable Chamber

A rectangular opening matching the board base must be cut in the ceiling of the cable chamber. The opening length must be 20 cm less than the board assembly width. Width is 40 cm for

front-accessible and multi-compartment boards, and 60 cm for rear-accessible boards. The opening edge must be reinforced with 4 × 4 cm angle iron.

For a comprehensive understanding of Cable Chamber, we highly recommend reviewing this article.

B) Installation on a Cable Trench

The trench length must be 20 cm less than the board assembly width. Trench width is 40 cm (front-accessible / multi-compartment) or 60 cm (rear-accessible), and its depth is 80 cm.

The trench bottom must be drainable or sloped to a floor drain and sump pit to prevent water accumulation.

Cable Chamber Opening & Trench Dimensions

| [Content Model] | MODEL |

|---|---|

| Board assembly width − 20 cm (for both models) | Opening / Trench Length |

| Front-Accessible & Multi-Compartment: 40 cm Rear-Accessible: 60 cm | Opening / Trench Width |

| 80 cm (for both models) | Trench Depth |

| 4 × 4 cm angle iron (for both models) | Edge Reinforcement |

| Sloped bottom or connected to floor drain & sump pit (for both models) | Drainage Requirement |

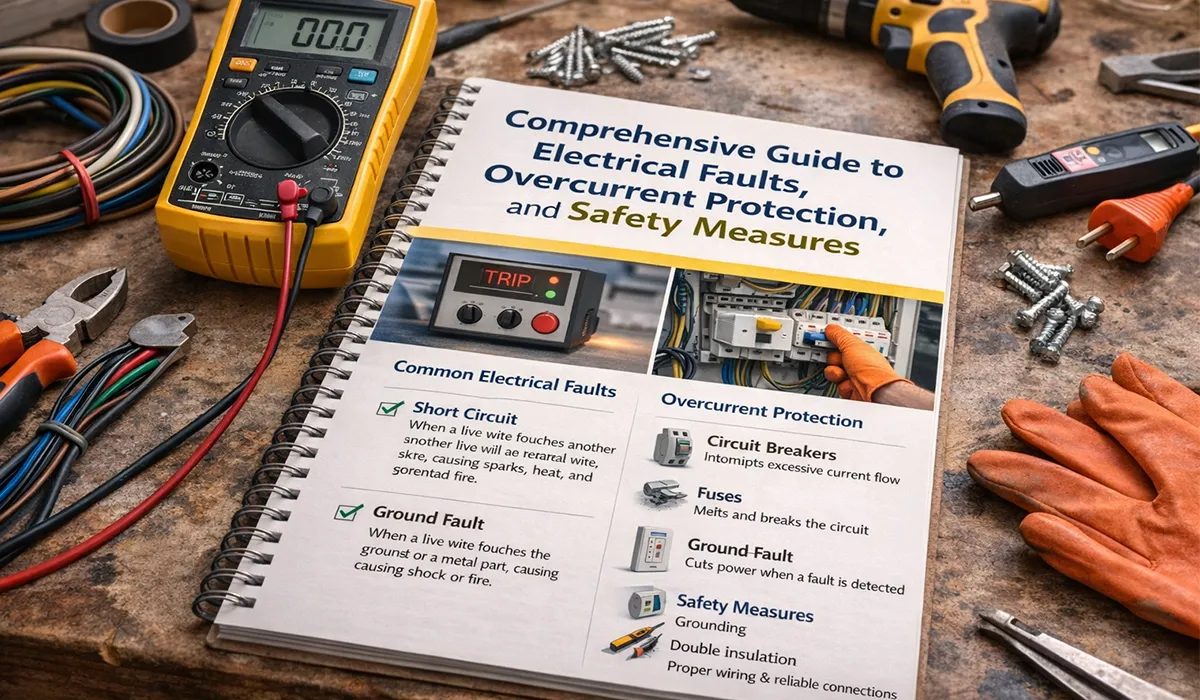

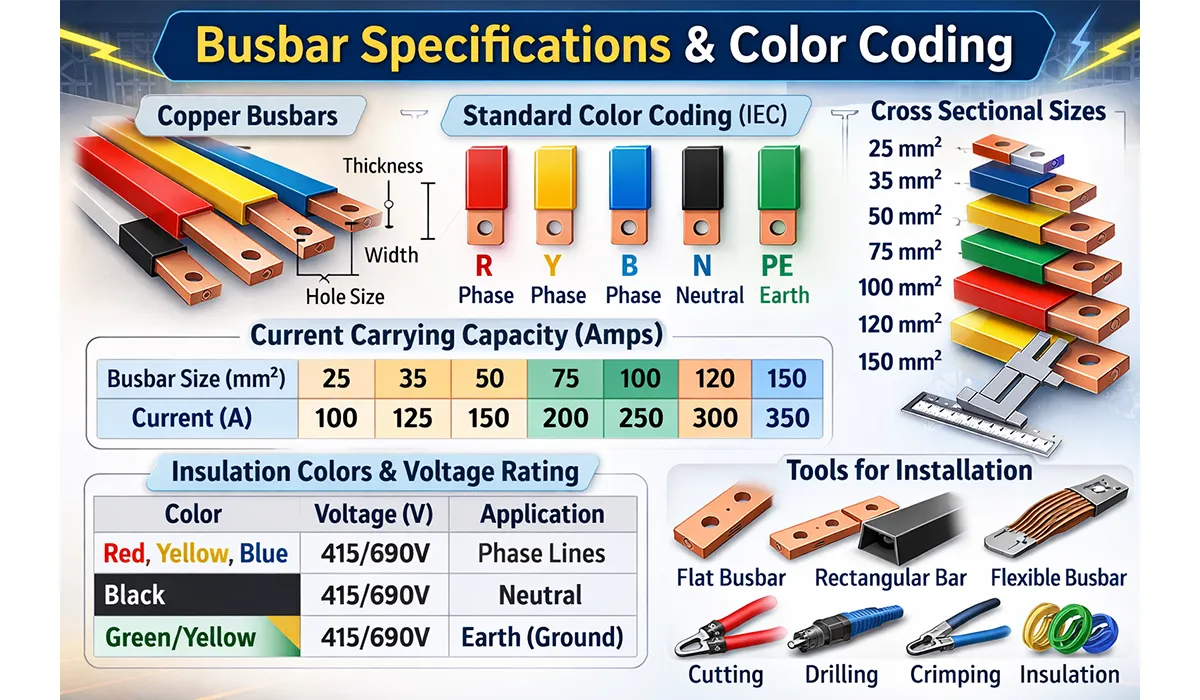

Busbar Specifications & Color Coding

Phase busbars must be painted with heat-resistant paint. The electrical capacity of phase busbars must not be less than 150% of the rated current of the main feeder breaker.

Neutral and earthing busbars must have a cross-sectional area not less than half of the phase busbar, running the full length of the board.

The minimum distance between busbars must not be less than 10 cm. Connection points must be clean and, if possible, silver-coated before tightening with copper or bronze washers.

Busbar Color Coding by Routing Plane

Here is the table you requested, formatted according to the provided template, while keeping the content in English:

| [Content Model] | MODEL |

|---|---|

| L1 (Red) | Busbar Routing Plane |

| Front busbar | Horizontal routing in horizontal plane |

| Top busbar | Horizontal routing in vertical plane |

| Left busbar | Vertical routing – front view |

| Front busbar | Vertical routing – side view |

Table 6 – Phase busbar color coding (L1 Red, L2 Yellow, L3 Blue) by routing plane.

Busbar Sizing Requirements

Correct busbar sizing is critical for thermal performance and system safety. The table below summarises the minimum sizing rules that must be applied when designing or verifying a

low-voltage distribution board.

| [Content Model] | MODEL |

|---|---|

| ≥ 150% of main feeder breaker rated current | Phase Busbar (L1, L2, L3) |

| ≥ 50% of phase busbar cross-sectional area; full board length | Neutral Busbar (N) |

| ≥ 50% of phase busbar cross-sectional area; full board length | Earthing Busbar (PE) |

| ≥ 10 cm | Minimum Inter-Busbar Spacing |

| Porcelain or synthetic resin | Busbar Support Insulators |

| Silver-coated (where possible) | Connection Surface Finish |

Table 7 – Busbar sizing and construction requirements for main low-voltage distribution boards.

Sub-Distribution Power Board – Wall-Mounted Type

This board may be installed surface-mounted or flush-mounted and consists of three separate main parts: the board box, the internal mounting frame, and the door frame with door.

- Board box up to 1 m height: sheet thickness 1.25 mm with punch-type or slotted conduit entries, secured with brass bushes and nuts.

- Board box over 1 m height: sheet thickness 1.5 mm.

- Internal frame: 1.5 mm steel sheet, removable with four screws.

- Door frame: at least 2 cm larger than board box on all four sides (surface-mounted).

Installation height: 210 cm from the top of the board to the finished floor level.

Lighting Sub-Board – Fuse / MCB Ratings by Circuit Type

In lighting sub-boards, the main switch is preferably a rotary type, protected by a cartridge fuse. All outgoing circuits must be protected by MCBs or cartridge fuses with the following

minimum rated capacities:

| [Content Model] | MODEL |

|---|---|

| Maximum 4 A | Alarm Bell & Call System |

| Minimum 10 A | Lighting Circuits |

| Minimum 16 A | Socket Outlets |

Table 8 – Minimum fuse / MCB ratings for outgoing circuits in lighting sub-boards.

is 4 A per mm² of conductor cross-section. Only one conductor may be connected to each terminal; connecting two or more conductors to a single terminal is not permitted.

Outdoor boards are floor-standing with galvanised steel frames and enclosures (minimum 2 mm sheet), or alternatively full-aluminium construction (minimum 3 mm sheet). The external roof

must be double-slope with edges turned inward, extending at least 5 cm beyond the board on all four sides. The door must have a sealing rubber and a special-key lock.

Boards must be installed on a concrete or brick platform 20–25 cm above finished street level. In humid areas, an angle-iron frame must be used to avoid direct board-to-concrete

contact.

Outdoor Board Maximum Dimensions

| [Content Model] | MODEL |

|---|---|

| 120 cm | Maximum Height |

| As required | Width |

| 40 cm | Depth |

| IPX3 | Minimum IP Rating |

| 20–25 cm above grade | Platform Height |

| 20–25 cm | Platform Wall Thickness |

Table 9 – Dimensions and installation requirements for outdoor power and lighting distribution boards.

Corrosion Protection & Surface Finishing Requirements

All board enclosures and structural components must be treated for corrosion protection before painting. The required process differs by climate and board type, as summarised below.

| [Content Model] | MODEL |

|---|---|

| Derusting, degreasing, phosphating | Surface Preparation |

| ✔ | All Climates |

| ✔ | Dry Climate |

| ✔ | Humid Climate |

| 1 coat | Primer Coat |

| ✔ | All Climates |

| ✔ | Dry Climate |

| Anti-rust primer | Finish Coats |

| Minimum 2 coats | Dry Climate |

| Minimum 3 coats | Humid Climate |

| Dedicated anti-rust + 1 primer + finish coat | Outdoor / Galvanised |

| – | Humidity Countermeasures |

| – | All Climates |

| Air circulation or internal heater to prevent condensation | Humid Climate |

| Sealed enclosure + IPX3 minimum | Outdoor / Galvanised |

Table 10 – Corrosion protection and painting specifications by climate and board category.

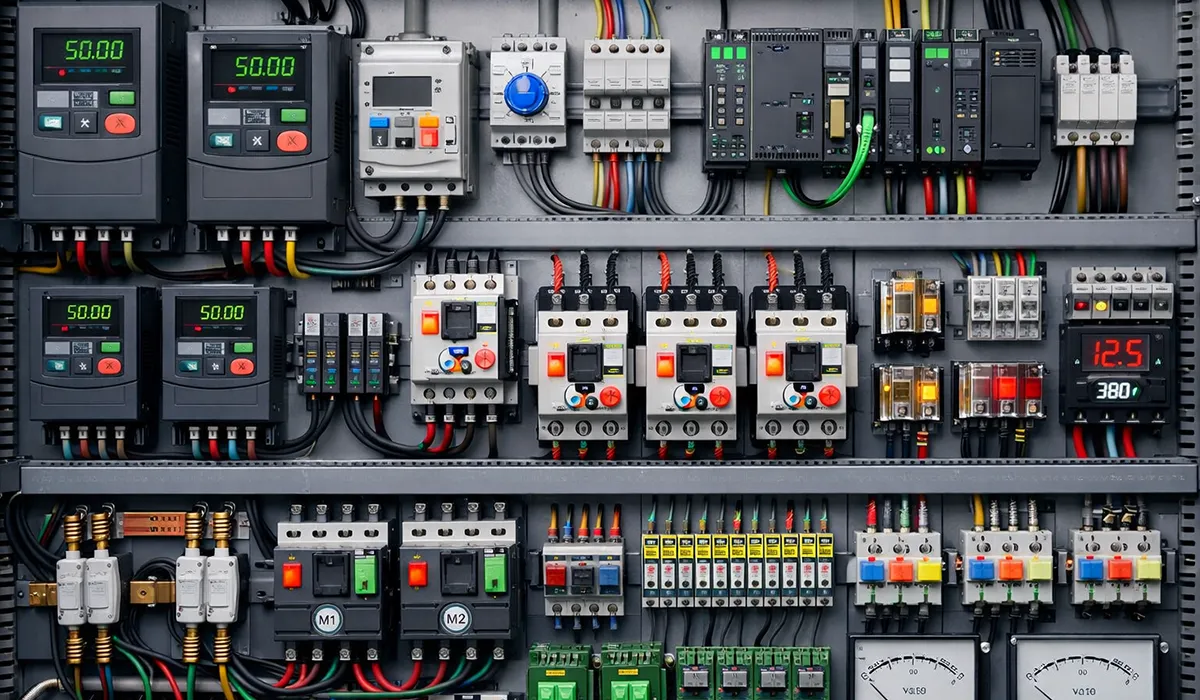

Devices, Instruments & Equipment Inside the Board

Typical devices found inside distribution boards fall into four categories:

| [Content Model] | MODEL |

|---|---|

| Voltmeter, Ammeter, Frequency Meter, Power Factor (cos φ) Meter, Wattmeter, Current Transformer, Tachometer, Hour Meter, Pressure Gauge | Measuring Instruments |

| Monitor electrical parameters in real time | Function |

| Cartridge & Knife Fuses, MCBs, Automatic Breakers (line & motor), Contactors (with / without thermal overload), Fused Switch, Rotary Switch, Knife Switch, Voltmeter & Ammeter Selector, Relays, Timers | Protection & Control Devices |

| Protect circuits from overload, short-circuit, and motor faults; control switching | Function |

| Red Signal Lamp (ON / energised), Green Signal Lamp (OFF / de-energised) | Alarm & Signal Devices |

| Provide visual indication of breaker and contactor status | Function |

| Phase Busbars, Neutral Busbar, Earth Busbar, Insulators, Cable Lugs, Terminal Blocks | Connection Hardware |

| Distribute power reliably from incoming supply to outgoing feeders | Function |

Table 11 – Categories and examples of devices installed inside low-voltage distribution boards.

Ammeter & Current Transformer Selection Guide

If the connected load exceeds 60 A, a current transformer (CT) and dedicated ammeter with a suitable ratio must be used. The ammeter capacity must not exceed 25% above the

maximum load. The table below provides example CT ratios for common load levels. Here is the table formatted according to your provided template:

Further exploration of Ammeter can be found in the following recommended reading.

| [Content Model] | MODEL |

|---|---|

| Up to 60 A | Maximum Load (A) |

| Direct (no CT required) | Recommended CT Ratio |

| Direct reading | Ammeter Full-Scale (A) |

| CT not mandatory below 60 A | Notes |

| 61 – 80 A | Maximum Load (A) |

| 100 / 5 | Recommended CT Ratio |

| 100 A | Ammeter Full-Scale (A) |

| 25% headroom above 80 A max | Notes |

| 81 – 160 A | Maximum Load (A) |

| 200 / 5 | Recommended CT Ratio |

| 200 A | Ammeter Full-Scale (A) |

| – | Notes |

| 161 – 320 A | Maximum Load (A) |

| 400 / 5 | Recommended CT Ratio |

| 400 A | Ammeter Full-Scale (A) |

| Example: 400 A load → 500/5 CT | Notes |

| 321 – 400 A | Maximum Load (A) |

| 500 / 5 | Recommended CT Ratio |

| 500 A | Ammeter Full-Scale (A) |

| Rule: select next standard ratio ≥ load × 1.25 | Notes |

| 401 – 600 A | Maximum Load (A) |

| 750 / 5 | Recommended CT Ratio |

| 750 A | Ammeter Full-Scale (A) |

| – | Notes |

| 601 – 800 A | Maximum Load (A) |

| 1000 / 5 | Recommended CT Ratio |

| 1000 A | Ammeter Full-Scale (A) |

| – | Notes |

Table 12 – Recommended current transformer ratios and ammeter full-scale values by load level.

Motor Equipment Control Boards

The main switch in motor control boards must be an automatic motor-protection breaker equipped with three ammeters and one voltmeter. The voltmeter selector switch must be a seven-position type. Sub-control circuits must include a contactor and a protective relay, except where a separate starter panel is provided — in that case a fused switch or rotary switch with separate fuses is acceptable. Two signal lamps (red = ON, green = OFF) must be provided for each circuit.

If you are looking for more information about Motor control center, it is recommended not to miss reading this article.

conclusion

In conclusion, selecting and installing the correct low-voltage power distribution board requires careful consideration of factors such as mounting, accessibility, and application needs. By understanding the classifications, size requirements, and safety standards, you can ensure that the board performs optimally while maintaining compliance with industry regulations. Whether it’s a main distribution board or a specialized lighting sub-board, this guide helps professionals make informed decisions, ultimately improving the reliability and safety of electrical installations.