In many places today, power outages are fairly common. With extreme weather, aging utility systems, and increasing electricity use, your neighborhood can experience a blackout, brownout, or volta

ge drop at almost any time. A reliable backup power plan is not a luxury but a basic requirement for comfort, safety, and continuity for home or small business concerns with 100amp service.

In this guide I write as both a technical writer and an engineer who works with practical, real-world backup power systems. My goal is to help you understand what people really mean when they say “100 amp generator,” how to choose the right generator for 100 amp service, and how to install it safely with the correct 100 amp transfer switch, wiring, and protection. Rather than just telling you to “buy the biggest unit,” we will walk step by step through whole-house generator sizing, load calculation, fuel choices, and code considerations.

We will focus on realistic 100 amp service backup power options: typically a 10–14 kW standby generator bundled with a 100 amp automatic transfer switch (ATS), or a properly connected 100 amp portable generator using an interlock. Along the way, I will show residential and light-industrial case studies, explain the difference between single-phase and three-phase 100A systems, and highlight the most important safety mistakes to avoid.

Alternatively, an audio version of this article is available below for your convenience.

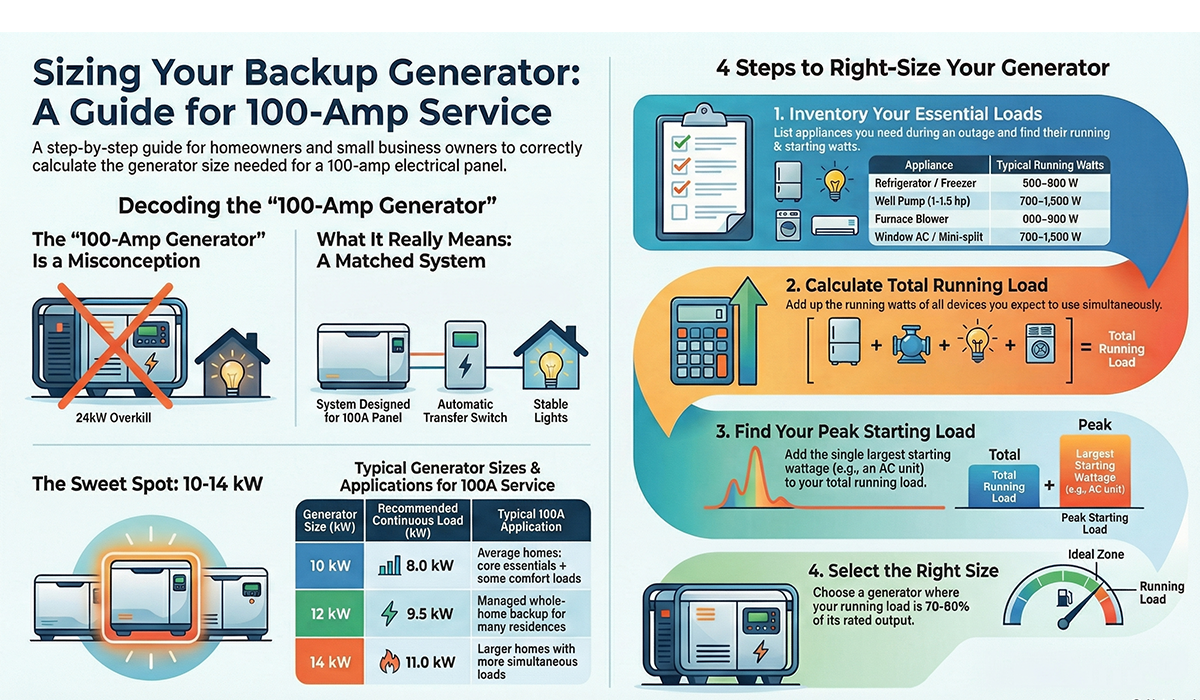

Generator Size vs Recommended Running Load (100A Homes)

The chart and table below summarize typical standby generator sizes commonly used with 100 amp service, and the recommended continuous running load when you follow the 70–80% loading guideline discussed in this guide.

| Generator Size (kW) | Approx. Max Continuous Load (kW) | Typical 100A Application |

| 8 kW | 6.0 kW | Smaller 100A homes – essential circuits only |

| 10 kW | 8.0 kW | Average 100A homes – core essentials + a few comfort loads |

| 12 kW | 9.5 kW | Managed whole-home backup for many 100A residences |

| 14 kW | 11.0 kW | Larger 100A homes with more simultaneous loads |

| 20 kW | 16.0 kW | High-demand or all‑electric 100A homes with less load shedding |

What Does “100 Amp Generator” Actually Mean?

When people search online for a “100 amp generator,” the phrase sounds very precise, but in practice it is often used in a loose way. Sometimes it refers to a generator that can really deliver around 100A of current at 240V continuously. Sometimes it refers to a generator and transfer switch bundle designed for a house that has a 100 amp panel. and sometimes it just refers to the rating of the 100 amp transfer switch included in the kit, not the generator itself.

To understand the real capability of a generators, we have to convert between amps, volts, and watts. The basic electrical power formula is very simple:

Power (W) = Voltage (V) × Current (A)

If you ask how many watts is 100 amps at 240V, the math is straight-forward:

240 V × 100 A = 24,000 W, or 24 kW at unity power factor (PF = 1.0).

So a true “100 amp generator” that can continuously feed 100A at 240V would need to be around 24 kW. In the real world, most residential backup systems do not use such a large unit. Retail categories labeled for “100A service” generally include 10–14 kW standby generator models bundled with a 100 amp automatic transfer switch. These are perfectly suitable for essential loads and for managed whole-house coverage using load shedding, but they do not produce a permanent 24 kW output.

For example, many well-known brands sell 10–13 kW standby generator packages that include a 100 amp service-disconnect ATS. The ATS is correctly matched to the house service rating (100A), while the generator kW rating is matched to the realistic load that will actually run during an outage. In this sense, the phrase “100 amp generator kit” is really shorthand for “a generator system designed to back up a 100 amp service,” not a promise of full 24 kW delivery.

Amps vs. Watts vs. kVA

To select the right generator for 100 amp service, it is important to clearly understand a few basic terms that electricians and engineers use all the time:

- Amps (A): The amount of electrical current flowing through a conductor.

- Volts (V): The electrical potential difference that pushes current through a load (for example, 120V or 240V in most homes).

- Watts (W) or kilowatts (kW): The real power actually consumed or delivered. This is what does useful work, such as turning a motor or heating an element.

- kVA (kilovolt-amperes): The apparent power, a combination of real power and reactive power. Generators are commonly rated in kVA.

The relationship between kW and kVA depends on the power factor (PF). Power factor is a measure of how efficiently the current is being converted into real work. Purely resistive loads, such as simple heaters, have a PF near 1.0. Motor loads, such as compressors and pumps, usually have a PF around 0.8 or even lower. Internationally, it is common to rate generators at 0.8 PF. That means a 100 kVA generator would deliver about 80 kW of real power at rated conditions.

Another key idea is the difference between running watts and starting watts (also called surge watts). Any device with an electric motor, like a refrigerator, well pump, or air conditioner, draws a short burst of higher current when it starts. This surge can be 2–3 times the normal running wattage, sometimes even more for heavy compressors. A good whole-house generator sizing process must account for these short but important surges, otherwise a generator that looks big enough on paper will trip its breaker in real use.

Table 1 below gives a simple feel for typical running watt ranges of common residential loads. Actual values vary by brand and efficiency, but this is a useful starting point when you plan a load calculation for a 100 amp generator system.

| Appliance / Load | Typical Running Watts |

| Refrigerator / Freezer | 500–800 W |

| Well Pump (1–1.5 hp) | 700–1,500 W |

| Furnace Blower | 600–900 W |

| Window or Mini-split AC | 700–1,500 W |

| Lighting & Small Electronics (group) | 300–1,000 W |

How to Size a Generator for a 100amp Service

The most important step in choosing any generator is sizing. If you choose a unit that is too small, it will overload whenever several large loads start at the same time. If you choose a unit that is too large, you will waste money on fuel, pay more upfront, and in some cases you can even damage a diesel engine by running it with a very light load for long periods.

For a typical home with 100 amp service, the question “what size generator for 100 amp service?” does not have a single answer. It depends on which loads you want to run during an outage and whether you are aiming for essential circuits only or a more ambitious managed whole-home strategy using load shedding. A common result for many houses is a 10–14 kW standby generator with a 100 amp ATS, but some larger or all-electric homes need 16–24 kW.

In professional electrical design, the standard approach is to perform a load calculation based on real connected loads and realistic usage patterns. A simplified version of that method is shown below, suitable for homeowners, facility managers, and small contractors.

Step-by-step generator sizing method for 100 amp service:

- Inventory essential and desired loads.

Walk room by room and list the appliances, equipment, and circuits that must stay powered during an outage. Typical essentials include refrigerators, freezers, well pumps, gas furnaces or boilers (for their control and fans), sump pumps, key lighting, networking equipment, and sometimes a small air-conditioning unit or mini-split. - Gather running watts and starting watts.

For each item on your list, write down the running watts from the nameplate or the user manual. For motor loads, also record the starting watts if the manufacturer provides them. If starting watts are not listed, you may assume 2–3× the running watts as a rough estimate. - Decide which loads can operate together.

Imagine a realistic worst-case scenario: evening time, with lights on, refrigerator cycling, internet router and PCs running, and maybe a well pump starting. Do you really need all heavy loads (like electric oven and dryer) at the same time? Many households can accept some manual management—for example, not running the oven during a storm outage—so that the generator size stays reasonable. - Calculate total running load and peak starting load.

Add up the running watts of all loads you expect to be on at the same time. Then find the single largest starting watt value and add it once to the running total (excluding that device’s own running watts while you do this step). The result is a good approximation of the maximum surge the generator needs to handle. - Apply a safe loading rule.

For long-term reliability and good fuel efficiency, most engineers recommend sizing so that your realistic running load is around 70–80% of the generator’s rated kW. A generator that always runs at only 20–30% load is not happy—it wastes fuel and, for many diesel units, encourages problems like wet stacking. - Select the generator kW rating.

Using the peak starting load and the preferred operating range (around 70–80% loading at typical use), choose a generator whose continuous kW rating fits your needs. For many 100A homes, this ends up in the 10–14 kW range if you are willing to manage large loads, or 16–24 kW if you want a more carefree, whole-house experience.

Example Calculation (Residential)

Let us walk through a realistic example for a detached house with 100 amp service. The homeowner wants to cover all essential loads plus allow limited comfort loads during an outage. After a walk-through, the list of important items looks like this:

- Refrigerator and freezer in the kitchen.

- A 1 hp well pump supplying domestic water.

- A gas furnace with an electric blower motor.

- Lighting circuits for main living areas and hallways.

- Internet router, a small switch, and one PC (for remote work).

- A small 9,000–12,000 BTU mini-split in the living room for summer comfort.

- Miscellaneous receptacles for phone chargers and small kitchen appliances.

| Load | Running Watts (approx.) | Starting Watts (approx.) |

| Refrigerator / Freezer | 700 W | 2,000 W |

| Well Pump (1 hp) | 1,000 W | 2,500 W |

| Furnace Blower | 800 W | 1,200 W |

| Lighting + Electronics | 1,000 W | 1,000 W |

| Mini-split AC | 1,200 W | 3,000 W |

Now we calculate the total running load if all of these are on at once:

700 + 1,000 + 800 + 1,000 + 1,200 = 4,700 W (4.7 kW).

The largest starting surge is the mini-split AC at around 3,000 W. For a realistic worst case, we take the total running load plus this largest starting surge, minus the mini-split’s own running watts (because we already counted them in the running total):

Peak starting load ≈ 4,700 W (running) + 3,000 W (mini-split surge) – 1,200 W (mini-split running) = 6,500 W.

So a generator needs to handle roughly 4.7 kW continuously with occasional peaks near 6.5 kW. If we want to keep our continuous loading in the 70–80% range, we divide the running load by 0.8:

4.7 kW ÷ 0.8 ≈ 5.9 kW.

In theory, a 7–8 kW generator could support this list if the homeowner is very careful with timing and does not add big extra loads. However, many professionals recommend stepping up to a 10–12 kW or even a 12 kW vs 14 kW generator for 100 amp panel comparison, especially if the system will use a 100 amp automatic transfer switch and smart load shedding modules. That way, the generator can also cover a 240V water heater or a second mini-split on a managed basis, without a large price jump.

Example Calculation (Light Commercial / Industrial)

Now consider a small metal workshop with a 100 amp three-phase service. The owner operates a 5 hp air compressor, a few small CNC machines, welding equipment, and office computers. During an outage, the goal is to keep one compressor, basic lighting, a single CNC, and the office running so that urgent orders can continue.

Because of the heavier motor loads and the preference for long runtime, the owner and engineer select a 100 amp diesel generator system. Diesel gensets in this size range are often rated in kVA and configured for 120/208V or 277/480V three-phase operation.

- 5 hp air compressor: about 4 kW running, 12–14 kW starting surge for a short moment.

- One small CNC machine: 3–4 kW running, small surge.

- Lighting and small office loads: 1–2 kW combined.

- Miscellaneous tools and receptacles: 1–2 kW allowance.

At first glance, the total running load might be around 8–10 kW, but the starting surge of the compressor is the real challenge. In many cases, engineers specify a 25–30 kVA three-phase 100 amp generator so that the compressor can start without dimming lights or tripping breakers. They also pay attention to balancing loads across the three phases to avoid overloading any single leg.

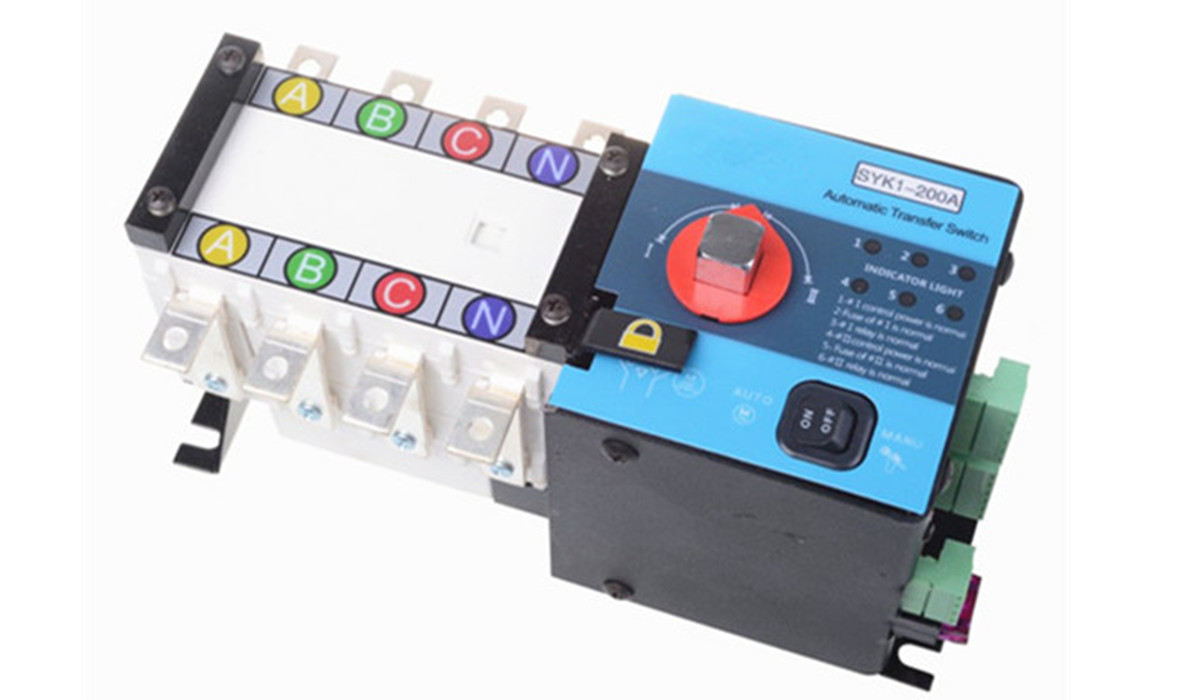

Transfer Switches & Interlocks for 100-Amp Systems

Any safe generator installation must include a reliable method to switch the building’s wiring between utility power and generator power. For a 100 amp service, this usually means either a 100 amp transfer switch or a properly installed generator interlock kit. Without such a device, there is a serious risk of backfeeding the electric utility lines, which is both illegal and extremely dangerous for line workers.

There are two main approaches for 100A systems:

- Automatic Transfer Switch (ATS): A dedicated switch that constantly monitors utility power. When it detects an outage, it starts the standby generator automatically and transfers the load from the grid to the generator. When utility power returns and stabilizes, it switches back. For a 100 amp service, a 100 amp automatic transfer switch is common, especially when using a 10–14 kW standby generator.

- Manual Interlock Kit: A more economical option often used with a 100 amp portable generator. A mechanical sliding plate installed on the panel’s front cover prevents the main utility breaker and the backfeed generator breaker from being on at the same time. The homeowner must start the generator and move the interlock manually, but the safety principle is the same: only one source feeds the panel at any moment.

A common question is whether a 100 amp transfer switch is adequate for a 15 kW generator. In most load-side applications, the answer is yes. The key idea is that the current through the ATS is limited by the generator’s kW rating, not by the full 100A service rating of the home. For example, a 15 kW generator at 240V produces around 62.5A at full output (15,000 W ÷ 240 V). A 100A-rated switch can easily handle this current, provided it is properly installed and listed to the correct standards.

Service-Entrance vs. Load-Side ATS

When we talk about generator transfer equipment, it is important to distinguish between service-entrance applications and load-side applications.

- Service-entrance rated ATS: This device takes the place of the main service disconnect. For a home with 100 amp service, the ATS must be listed as suitable for service-entrance use, comply with UL 1008, and be rated for 100A. It is installed between the utility meter and the main panel. When the generator runs, the entire panel is supplied through this switch.

- Load-side or subpanel ATS: In many homes, only selected critical loads are backed up. In this design, a 100 amp ATS feeds a smaller subpanel that contains only prioritized circuits. The original main panel remains the service disconnect, while the ATS is simply a load-side device, still subject to code but not replacing the main service switch.

Both types must be installed in accordance with local electrical codes and inspected by the Authority Having Jurisdiction (AHJ). Correct neutral switching, grounding, and bonding depend on whether the generator is treated as a separately derived system, so it is not a casual DIY decision.

Load Shedding & Managed Whole-Home

Because most 100 amp service backup power options use a 10–14 kW standby generator instead of a full 24 kW unit, smart load management is very important. Load shedding for 100 amp generators relies on small electronic modules installed on selected high-demand circuits, such as large air conditioners, water heaters, or electric dryers.

These smart management modules (SMMs) continuously watch the generator’s output. When the total load approaches a set limit, the module temporarily disconnects its managed circuit. This frees up capacity for critical loads. Once the heavy device is no longer needed or the total demand drops, the module automatically reconnects it.

With this approach, a 10–14 kW standby generator bundled with a 100 amp transfer switch can effectively behave like a whole-house generator for many 100A homes, as long as the largest loads are managed instead of running all at once.

Fuel, Runtime, Noise & Placement (Spec Trade-Offs)

After you know the correct kW range and have chosen the right 100 amp transfer switch strategy, the next big decision is fuel type. Fuel choice will strongly affect runtime, maintenance, cost, and system complexity.

Here is a quick comparison of the most common fuel options for 10–24 kW standby generators and 100 amp portable generator systems:

| Fuel Type | Key Advantages | Key Disadvantages |

| Natural Gas (NG) | No on-site storage, long runtime, clean burning. | Depends on gas pipeline, slightly lower output than LP. |

| Liquid Propane (LP) | Stored on-site, long shelf life, clean. | Requires tank, higher consumption for large units. |

| Diesel | High efficiency, strong under heavy load, long engine life. | Higher emissions, more maintenance, fuel storage rules. |

| Gasoline | Easy to find, low initial cost for portable units. | Short fuel shelf life, poor for continuous heavy use. |

For a permanently installed whole-house generator, natural gas or propane are the most common choices. They allow the system to run for many hours or days without refueling. A 100 amp diesel generator is popular in light-industrial applications where fuel efficiency and heavy-duty performance are more important than quiet operation or ultra-clean emissions.

Runtime is only one side of the story. Noise and placement are also critical. Most modern residential standby generators operate in the range of 60–70 dB at a few meters, similar to a typical air-conditioning unit. Even so, local noise ordinances may limit where you can place the unit.

General placement guidelines include:

• Install the generator outdoors in a well-ventilated area.

• Keep at least 5 feet (or local code distance) from windows, doors, and air intakes to avoid carbon monoxide (CO) hazards.

• Set the unit on a level, solid base such as a concrete pad.

• Leave enough clearance around all sides for cooling air and maintenance access, typically 18–36 inches.

• Consider your neighbors and bedroom windows when choosing the location, to reduce noise complaints.

Single-Phase vs. Three-Phase & Voltage Options

Most homes in North America use single-phase 120/240V service. A generator for 100 amp service in this context is usually a single-phase unit that feeds two 120V legs in the panel, providing both 120V circuits and 240V for larger appliances.

Small factories, workshops, and commercial buildings often use three-phase service, such as 120/208V or 277/480V. In that case, a single-phase 100 amp generator will not be appropriate. Instead, you need a three-phase 100A generator sized for the expected kVA and designed to start large motors without excessive voltage drop. Proper load balancing across all three phases is essential to avoid overheating conductors and breakers.

Selecting a 100-Amp-Class Generator System

Once you know your approximate kW requirement, service type, and fuel preference, it is time to evaluate specific products. Here are key factors that engineers and experienced contractors examine when comparing the best 100 amp home standby generators:

- Rating type: Check whether the generator is rated for standby, prime, or continuous duty. For residential backup, a standby rating with conservative assumptions is preferred.

- Total Harmonic Distortion (THD): Low THD (typically under 5%) is important for sensitive electronics such as computers, networking gear, LED lighting, and medical devices.

- Alternator and controller quality: A good alternator maintains stable voltage and frequency, while a robust controller manages starting, fault detection, and exercise mode.

- Monitoring features: Many modern 10–14 kW standby generators support Wi-Fi or cellular monitoring so you can see status, alarms, and run hours from a phone app.

- Warranty and local service: A long warranty is only valuable if local technicians and spare parts are readily available. Check the service network coverage in your area.

In the retail market, typical 100 amp generator bundles include a 10–13 or 14 kW air-cooled standby generator with a matching 100 amp ATS. These packages are popular because they give a balanced solution: enough power for essential loads or managed whole-home use, without the extreme cost and fuel consumption of a much larger 24 kW unit.

When selecting a generator for your 100 amp service, consider systems that ensure precise power distribution, much like how a busbar processing machine helps streamline electrical systems efficiently. Learn more about these machines on our Busbar Processing Machines page.

Installation Cost Drivers & Timeline

A complete generator project involves much more than simply buying a box and placing it on a pad. Electrical work, fuel piping, permits, inspections, and commissioning all add to the total cost. For a typical 10–14 kW standby system with a 100 amp transfer switch, professional installation often falls in the range of several thousand dollars.

Major cost drivers include:

- Generator unit cost: Larger kW ratings and premium brands cost more. A 10 kW air-cooled unit is significantly cheaper than a 24 kW liquid-cooled model.

- Transfer switch type: A manual interlock plus inlet is the least expensive, while a service-entrance rated 100A ATS with load shedding modules costs more.

- Fuel system: For natural gas, the gas line may need to be upsized and extended; for propane, you must install and connect a storage tank; for diesel, you may need a day tank and spill containment.

- Electrical infrastructure: Costs for trenching, conduit, heavy-gauge copper or aluminum conductors, concrete pad, and any panel upgrades or breaker replacements.

- Permits and inspections: Local code requirements from the AHJ, including electrical, building, and sometimes zoning or environmental permits.

- Commissioning and testing: Final checks, simulated outage tests, and optional load bank testing to verify performance under realistic load.

From start to finish, a straightforward residential installation may take a few days of on-site work spread over several weeks, depending on permit timelines and utility coordination. Complex light-industrial projects can take longer, especially if utility protection studies and selective coordination studies are required.

Safety, Codes & Best Practices

Generator installations must always follow national and local electrical codes. These rules are not just bureaucratic paperwork—they exist to protect people and property. For residential and small commercial systems, the main reference is usually the National Electrical Code (NEC), particularly Article 702, which covers optional standby systems.

Some of the most important safety and code topics include:

- Backfeed prevention: Never connect a generator directly to a panel or a receptacle without proper transfer equipment. A 100 amp transfer switch or listed interlock is mandatory to prevent generator power from feeding back onto utility lines.

- Transfer switch standards: Transfer switches must be listed for their purpose, such as UL 1008 for automatic transfer equipment. Do not use improvised or unlisted devices.

- Grounding and bonding: Whether the generator is considered a separately derived system depends on neutral switching in the ATS. This directly affects how and where grounding electrodes and bonding jumpers are installed.

- Labeling and signage: Clear labels at the service entrance and at the generator location help first responders and utility workers understand the system. Many codes require permanent plaques stating the presence and type of standby generator.

- Wire sizing: For 100 amp feeders, #3 AWG copper or #1 AWG aluminum is a common minimum, but derating factors such as ambient temperature, installation method, and distance must be considered.

In industrial settings and large assemblies, designers may also apply standards such as IEC 61439 for low-voltage switchgear and controlgear, and they may perform arc-flash studies to define safe working distances and PPE. Even for a modest 100 amp generator system, it is wise to consult a licensed electrician or professional engineer to verify that all details are correct.

Maintenance & Reliability

A standby generator is only useful if it starts and carries load when the lights go out. Regular maintenance and testing are therefore just as important as proper installation. Many problems that cause generators to fail during real outages are simple issues like old fuel, weak batteries, or overdue oil changes.

Good practice for generator maintenance schedule and reliability includes:

- Exercise mode: Configure the generator to run automatically once a week for a few minutes. This keeps oil distributed, charges the battery, and reveals obvious faults.

- Oil and filter changes: Follow the manufacturer’s hour-based schedule, often every 100–200 hours or annually, whichever comes first.

- Fuel care: For diesel and gasoline, use clean, fresh fuel and consider additives or fuel polishing for long-term storage. For propane and natural gas, periodic leak checks are important.

- Load testing: At least once or twice a year, run the generator under real or simulated load to confirm that it can carry the intended circuits without unstable voltage or frequency.

- Recordkeeping: Maintain a simple log of service, tests, and repairs. This is helpful for warranty claims and for diagnosing recurring problems.

Advanced Installation and Electrical Integration Details

For many homeowners, choosing a generator and having a licensed contractor install it is enough. However, for engineers, electricians, and technical managers, it is useful to look deeper into wire sizing, subpanel design, and safe operating procedures for portable units.

Wire Sizing and Ampacity for 100-Amp Service

Correct wire sizing is vital for safety and performance. If a conductor is too small for the current it carries, it can overheat and damage insulation or even start a fire. For a 100 amp feeder, the NEC typically calls for at least #3 AWG copper or #1 AWG aluminum, but this is only a starting point.

Factors that influence final wire selection include:

• Length of run and allowed voltage drop.

• Ambient temperature and installation conditions (in conduit, underground, grouped with other circuits, etc.).

• Terminal temperature ratings on breakers and equipment.

• Whether the conductors are copper or aluminum.

Subpanel Installation for Critical Loads

One common design for 100 amp portable generator setups is to use a dedicated subpanel for critical loads. In this arrangement, selected circuits are moved from the main panel into the subpanel, which can then be energized either by the utility (through a feeder breaker) or by the generator (through a transfer switch or interlock).

Important points for subpanel design include:

- Neutral and ground separation: In a subpanel, neutrals and grounds must remain isolated. The neutral bus must not be bonded to the panel enclosure; that bond exists only at the main service disconnect.

- Feeder breaker sizing: The breaker feeding the subpanel must be correctly sized for the feeder conductors and the subpanel rating.

- Circuit relocation: Critical circuits are carefully moved from the main panel to the subpanel, so that the generator only powers selected loads when in backup mode.

- Clear labeling: Both panels should be clearly labeled so that anyone servicing the system understands which circuits are backed up and how the transfer mechanism works.

Safe Operation Using Portable Generator and Interlock

When using a 100 amp portable generator with an interlock kit, the user must follow a clear and disciplined operating sequence to avoid dangerous situations and accidental overloads. A typical safe sequence is:

- Turn off or disconnect all large loads in the house.

- Move the interlock so that the main breaker can be switched OFF before the generator breaker is turned ON.

- Connect the generator to the exterior inlet box with the properly rated cord.

- Start the generator and let it warm up for several minutes until it reaches stable speed and voltage.

- Turn ON the generator backfeed breaker (now allowed by the interlock) to energize the panel or subpanel.

- Bring loads back online one by one, starting with the smallest and leaving heavy motor loads for last.

Following this procedure reduces the risk of tripping the generator breaker with a large simultaneous inrush of starting current. It also reinforces the habit that the main utility breaker must always be off whenever the generator is backfeeding the panel.

Efficient power management and integration are key when sizing your generator. Similarly, combining multiple functions in a single busbar machine maximizes productivity and reduces space. Explore the advantages of this approach in our Benefits of Combining Multiple Functions in a Single Busbar Machine article.

The Professional Engineer’s Perspective on Sizing and Investment

From a professional engineering point of view, the most common mistake in generator projects is oversizing. Many owners believe that “bigger is always safer,” so they jump to a much larger kW rating than needed. In reality, this can be a poor investment: fuel consumption rises sharply at low load factors, and diesel engines in particular suffer from wet stacking and carbon buildup if they seldom see 60–80% of rated output.

On the other hand, undersizing the generator for 100 amp service is also dangerous. A small unit that is constantly overloaded will trip, stall, and eventually wear out. Critical loads may drop unexpectedly during storms, exactly when they are most needed.

The best strategy is simple but requires a bit of discipline: perform a realistic load calculation, identify what is truly essential, and then choose a generator size that allows a comfortable 70–80% loading during typical use. Combine this with a well-designed 100 amp transfer switch, proper wiring and grounding, and a routine maintenance plan. With that approach, a 10–14 kW standby generator or a carefully selected 100 amp diesel generator can deliver reliable backup power for 15–20 years or more, protecting both your electrical equipment and your peace of mind.

Like choosing the right generator for 100 amp service, selecting the appropriate busbar system ensures reliable power flow. Our Busbar Processing Machine offers an advanced solution for efficient electrical distribution.

Conclusion

In conclusion, selecting the right generator for your 100 amp service is a crucial step in ensuring reliable backup power during outages. By understanding the necessary sizing, proper transfer switches, and safety considerations, you can confidently choose a generator that fits your home or small business needs. Whether opting for a 10–14 kW standby generator or a carefully sized portable unit, a well-planned power solution will provide both comfort and safety. Always remember to perform a detailed load calculation, account for fuel choices, and prioritize efficient installation for long-term reliability. With the right generator and setup, you’ll be prepared to face any power interruptions with ease.

FAQs About 100 Amp Generator Systems