In many parts of the world, the way we live at home is changing very fast. We add more air conditioners, install strong electric ovens, charge electric vehicles in the garage, and sometimes even run a small workshop or home office from the same house. All of these new loads need a strong and reliable electrical backbone. For most modern houses, that backbone is a properly designed and correctly installed 200 amp panel.

As a technical writer and engineer from Asia working with residential and light‑commercial projects, I often see the same problem: the house is beautiful, the interior is new, but the electrical panel is very old and undersized. Breakers trip all the time, lights dim when a big appliance starts, and sometimes there is even a burning smell from the panel. In many cases, the root cause is a 60 amp or 100 amp service trying to support a lifestyle that really needs a 200 amp service.

In this detailed guide, I will explain in simple language what a 200 amp panel is, how it works, when you really need one, and what you should expect in terms of conductor size, safety standards, installation steps, and cost. My goal is to help homeowners, DIY enthusiasts, and even junior electricians understand the full picture so you can make smart, safe decisions for your house or small building.

Throughout the article, I will also touch a little on code requirements like the National Electrical Code (NEC), UL 67 panelboard listing, and enclosure ratings such as NEMA 1 and NEMA 3R, because these keywords are important not only for safety and inspection, but also if you are searching for the right product online.

For your convenience, if you prefer listening, you can listen to the rest of this article via the audio file below.

What Is a 200 Amp Panel? Basic Idea and Main Components

The electrical panel is sometimes called a breaker box, a service panel, or a load center. No matter the name, it has one main job: to take the incoming power from the utility company and safely distribute that power to all the circuits in your house.

When we say “200 amp panel,” we are talking about the maximum current that the panel is designed to handle. In simple words, the panel can safely carry up to 200 amperes of electrical load at any moment, if everything is wired correctly and installed according to code. For comparison, many older houses still have 60 amp or 100 amp panels, which are usually not enough for a modern lifestyle with many electrical devices.

In most single‑family houses in North America, the main service is single‑phase, 120/240 volts. That means your 200 amp panel is able to provide up to 200 amps at 240 volts across the whole service, not 200 amps on every circuit. All branch circuits share this total capacity, and the distribution is controlled through different circuit breakers.

To understand your 200 amp panel better, let us review the main components you will usually see inside:

Main breaker or main lugs

Most standard residential 200 amp panels have a large main breaker at the top. This main breaker is like a master switch for the entire panel. If there is a serious problem, you can shut off all power to the house by switching off the main breaker. It also gives overcurrent protection for the whole service; if the total current exceeds what the panel can safely handle, the main breaker trips.

Some panels, called “main lug only” panels, do not have a main breaker. Instead, they are designed to be used as subpanels or in systems where the main disconnect is located somewhere else, such as near the meter. In that case, the panel is fed from an upstream breaker, and the lugs inside the panel simply receive the incoming wires.

Busbars

Bus bars are the thick metal strips inside the panel that carry power from the main breaker to the individual circuit breakers. They are usually made from copper or aluminum. Copper bus bars offer better conductivity and long‑term reliability, but aluminum bus bars are also widely used and can be safe if they are properly designed and installed. When you plug a circuit breaker into the panel, the breaker’s metal clip grips onto the bus bar, and that is how power flows from the main service into each branch circuit.

Panels depend on busbars, and busbar quality is all about good material and precise forming. If you want to understand what “good busbar work” looks like in the real world, this deep dive explains bending methods, tooling, and accuracy considerations that affect reliability.

Circuit breakers

Circuit breakers are the small switch‑like devices lined up inside the panel. Each one protects a specific branch circuit: for example, kitchen receptacles, living room lights, laundry sockets, or the air‑conditioning unit. If a circuit becomes overloaded or there is a short circuit, the breaker trips and disconnects that circuit to prevent overheating and fire.

In modern installations, we also use special safety breakers:

- GFCI (Ground‑Fault Circuit Interrupter) breakers for wet locations such as bathrooms, garages, outdoor circuits, and sometimes kitchens. These breakers protect human life by quickly cutting power if they detect a difference between the outgoing and returning current, which can indicate a ground fault through a person’s body.

- AFCI (Arc‑Fault Circuit Interrupter) breakers for many living areas such as bedrooms and family rooms. These breakers are designed to detect dangerous electrical arcing that can start a fire behind walls or inside cords, even when the total current is not very high.

Neutral and ground busbars

Inside the panel, you will find bars with many screw terminals. Some are for neutral wires (usually white or gray), and some are for grounding wires (usually bare or green). In the main service panel, neutral and ground are bonded together and connected to the metal enclosure and the grounding electrodes (e.g., ground rods). In subpanels, the neutral and ground must be isolated, which means they are kept separated and not bonded together.

This difference is very important for safety. The grounding system provides a low‑resistance path for fault current, so that a breaker trips quickly during a fault. The neutral provides a return path for normal load current. Mixing these improperly can create shock hazards and strange current paths.

Number of spaces and circuits

A typical 200 amp breaker box for a modern home will have around 40 to 42 spaces for standard‑size breakers. Some models offer even 54 or 60 spaces. Having more spaces is very useful if you plan to add new loads in the future—for example, an EV charger, a heat pump, or a home workshop.

Even when a 200 amp panel has 40 spaces, the total number of circuits can sometimes be higher if the panel is listed for tandem or “twin” breakers. However, you must always follow the manufacturer’s instructions; not every space is allowed to take tandem breakers.

NEMA enclosure rating: indoor vs outdoor

Panels installed indoors in dry locations, such as basements or utility rooms, usually have a NEMA 1 rating. Panels that are installed outside, exposed to rain and sun, need a NEMA 3R or similar weather‑resistant enclosure. These outdoor boxes have rain‑tight covers, proper drainage, and sometimes gasketed doors to keep water out and protect the breakers inside.

Interrupting rating (AIC) and UL 67 listing

Each panel and breaker also has an interrupting rating, sometimes shown as AIC (amperes interrupting capacity). This value tells you how much fault current the breaker can safely interrupt without exploding or failing. In residential systems, typical AIC ratings are 10,000 amps or 22,000 amps, depending on the available fault current from the utility.

For safety and code compliance, you should always choose a 200 amp panel that is listed and labeled according to UL 67 for panelboards. This listing means the panel has passed strict tests for insulation, mechanical strength, temperature rise, and many other parameters. For the enclosure itself, UL 50 or related standards apply.

When Do You Really Need 200 Amp Service? Load Planning and Real Examples

Now that we know what a 200 amp panel is, the big question is: do you actually need one? Not every small house needs a 400 amp service, but in many cases, a 100 amp service is clearly not enough anymore.

In the past, many homes were built with gas heating, gas water heaters, and only a few electrical appliances. A 60 amp or 100 amp panel was enough. But today we see:

- Larger HVAC systems (central air‑conditioning, heat pumps).

• Electric ranges and ovens.

• Electric water heaters and sometimes tankless units.

• Clothes dryers.

• Hot tubs or spa pumps.

• Multiple computers, large TVs, and home entertainment systems.

• EV chargers using 40–50 amp circuits for many hours.

Each of these loads adds pressure to the electrical system. When we combine many of them, the total demand can easily exceed what a 100 amp service should safely provide.

Simple way to estimate your load

A basic formula to estimate current is:

Amps = Watts ÷ Volts

For example, an electric range might be 8,000 watts at 240 volts:

Amps = 8,000 ÷ 240 ≈ 33 amps

A Level 2 EV charger may draw 40 amps continuously, and a central air‑conditioning system may need 20–30 amps. Just these three loads can already reach almost 100 amps, without counting lights, receptacles, and other appliances.

Because of this, the National Electrical Code recommends observing an 80% rule for continuous loads: a panel should not be loaded more than 80% of its rating for long periods. For a 200 amp panel, that means around 160 amps of continuous load. This safety margin helps prevent overheating and prolongs equipment life.

Typical panel sizes for different houses

We can think about the comparison in a simple way:

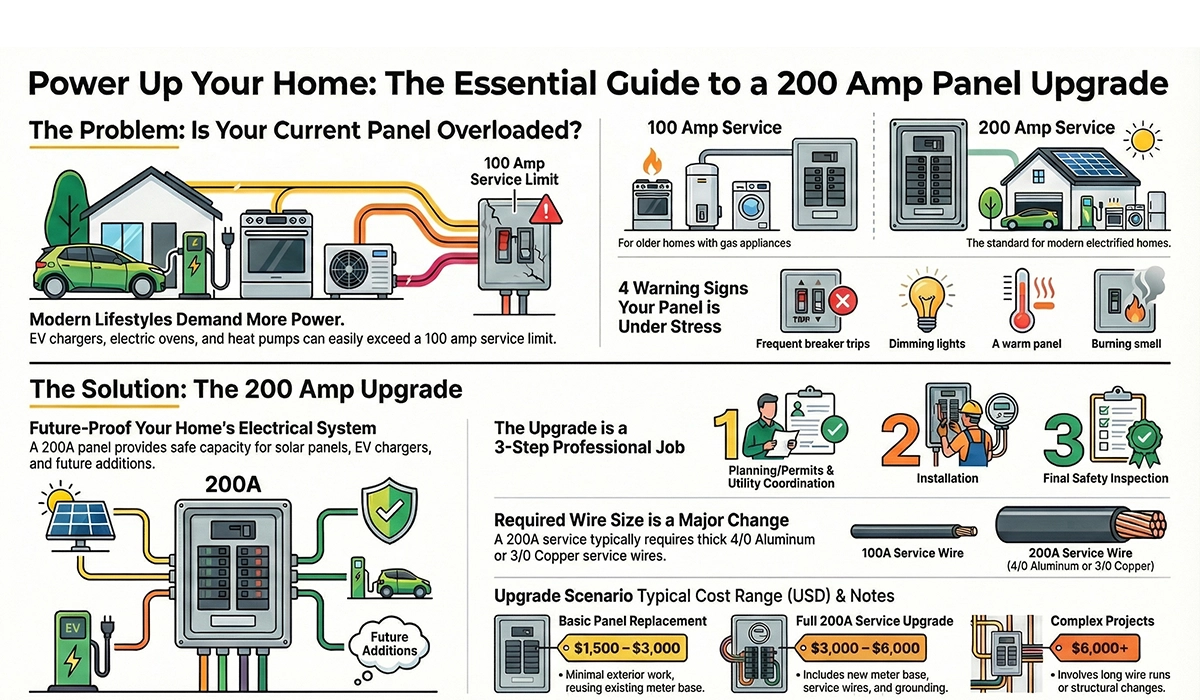

- 100 amp panel: Very small or older homes, often using gas for most heavy loads. Little spare capacity. Not recommended for houses with EV chargers or many large electric appliances.

- 200 amp panel: The modern standard for many single‑family homes. Enough capacity for typical HVAC systems, electric ranges, and one EV charger, plus room for future additions.

- 400 amp panel: Large luxury homes, fully electric houses with multiple EV chargers, large workshops, or special loads like big pools and spa systems.

Instead of focusing only on square footage, consider your lifestyle: do you plan to switch from gas to electric appliances? Do you want a home office with many computers and servers? Are you planning to install rooftop solar or battery storage? Once you think about the next 10–20 years, you will see why 200 amp service is often the minimum smart choice today.

Warning signs that your current panel is too small or too old

Even if you are not planning a big renovation, your current panel may be sending you signals that it is under stress:

- Frequent tripping: If breakers trip often when you run a microwave and toaster at the same time, or when the AC starts, your system may be overloaded.

- Dimming lights: If the ceiling lights dim or flicker every time a large appliance starts, this is a sign that your panel and service may be struggling with voltage drop or load spikes.

- Heat and smell: A warm panel cover, buzzing noises, or any burning smell near the breakers is a serious warning. Turn off power and call an electrician immediately.

- Rust and corrosion: Moisture damage on or inside the panel can compromise safety and should be inspected by a professional.

- Very old panels: Some brands and models from decades ago are now known to have serious safety problems. A panel older than 25–30 years, especially if it has never been inspected, is a strong candidate for replacement.

Upgrading to a 200 amp panel in these situations is not just about convenience; it is about protecting your family and your property from fire and shock hazards.

Conductor Sizing for 200 Amp Service: NEC Pathway in Simple Words

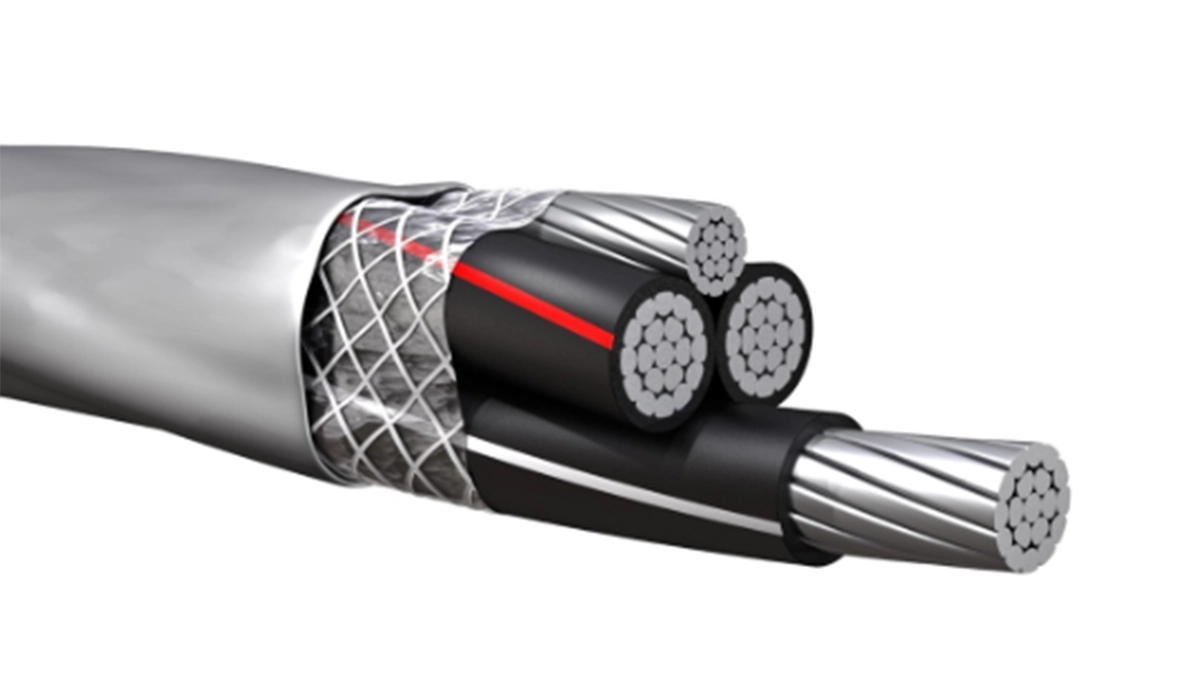

One big difference between a 100 amp and a 200 amp service is the size of the conductors (wires) that bring power from the utility to your main panel. A 200 amp service requires thicker conductors so they can carry the higher current without overheating.

In many dwelling applications, the National Electrical Code allows the following standard sizes for a 200 amp service entrance:

- 4/0 AWG aluminum conductors, or

• 3/0 AWG copper conductors.

These sizes are based on tables such as NEC 310.12 (for dwelling services) and include safety margins for typical residential conditions. Copper has better conductivity and can carry more current than aluminum at the same size, so the copper conductor can be smaller. Aluminum requires one size larger, but it is lighter and usually cheaper.

Service entrance, feeders, and branch circuits

It is useful to separate three different types of conductors in your home:

- Service entrance conductors: These wires run from the utility connection and meter to your main 200 amp panel. When you upgrade from 100 amp to 200 amp service, these are almost always replaced with larger conductors.

- Feeders: These are larger conductors that run from the main panel to a subpanel in another part of the house, such as a detached garage, a basement workshop, or a second‑floor panel.

- Branch circuits: These are the typical wires that run from circuit breakers to lights, outlets, and small appliances.

When you upgrade your service to 200 amps, you usually do not have to change every branch circuit in the house. If the existing branch circuits are in good condition and meet basic code requirements, they can remain in place. The main focus of the upgrade is the new 200 amp panel, the new service entrance conductors, and sometimes new feeders to important subpanels.

Voltage drop and long runs

For long runs, especially for detached buildings or long driveways, voltage drop becomes more important. The longer the wire, the more resistance it has, and the more voltage you lose along the way. Good practice is to maintain no more than 3% voltage drop on branch circuits and no more than 5% total drop on feeders plus branch circuits combined.

In simple language, if your garage is very far from your house and you want to feed it with a 60 amp subpanel, you may need thicker conductors than the minimum size listed in the code to keep voltage drop under control. A licensed electrician can calculate this for you based on distance and load.

How to Choose the Right 200 Amp Panel: Practical Selection Guide

When you search online or visit a supplier, you will see many different 200 amp load center models from different manufacturers. The amp rating alone is not enough to choose the right panel. Here are some key criteria you should check carefully.

Number of spaces and flexibility

If you are upgrading from a very old and crowded panel, you should not buy another panel that will become crowded again in a few years. It is wise to choose a 200 amp panel with at least 40 spaces, and many electricians prefer models with 54 or 60 spaces for modern homes. Extra space makes it easier to add new circuits for future needs, such as:

- A dedicated circuit for a home office.

• A circuit for a hot tub or sauna.

• New split‑system air conditioners.

• An EV charging station.

• A future solar backfeed breaker if allowed by the design.

Busbar material: copper vs aluminum

Bus bars and internal connections can be made from copper or aluminum. Copper bus bars cost more but provide long‑term stability and are less sensitive to certain corrosion issues. Aluminum bus bars are accepted and widely used if the panel is designed correctly and installed with the right torque and anti‑oxidant compound where required.

From a homeowner’s point of view, both can be safe. If your budget allows, a panel with copper bus bars is often a nice upgrade for extra reliability.

Plug‑on neutral design

Many modern panels include “plug‑on neutral” rails that allow you to install AFCI, GFCI, or dual‑function breakers without extra pigtail wires going to the neutral bar. This design keeps the panel interior much cleaner and makes installation faster for the electrician. If you plan a new panel, it is worth choosing a design that is ready for these advanced breakers, because code requirements for AFCI and GFCI protection are growing every year.

Interrupting rating and local fault current

The panel and breakers must have an interrupting rating that is equal to or higher than the available fault current from your utility service. In many residential neighborhoods, 10 kAIC breakers (10,000 amp interrupting capacity) are common, but in areas with strong utility infrastructure, 22 kAIC or higher may be required.

Your electrician can check with the utility or calculate the available fault current and choose appropriate breakers and panels.

Indoor panel or outdoor panel (NEMA 1 vs NEMA 3R)

If your main service panel will be located outside, you must choose a load center with an outdoor‑rated NEMA 3R enclosure. These enclosures are rain‑tight, often with a sloped top or special drip design so water does not collect, and sometimes with a latch or lock to prevent unauthorized access.

For indoor installations in dry locations, NEMA 1 enclosures are fine and more compact. In some regions, local code prefers outdoor meter‑main combinations, so you might have an outdoor 200 amp main disconnect and an indoor 200 amp subpanel.

Step‑by‑Step Overview of a 200 Amp Service Upgrade

Upgrading to a 200 amp panel is not just a simple swap of one box for another. It is a complex project that involves coordination with your local utility, permits from the building department, and strict safety procedures. Here is a simplified step‑by‑step view of what usually happens during a typical upgrade from 100 amp to 200 amp service.

If your upgrade involves a detached garage, long feeders, or any underground run, conduit choice and burial depth matter a lot. This guide covers common conduit types, practical trench prep, and typical NEC burial-depth logic so your underground wiring lasts for decades.

Planning, load calculation, and permits

First, a licensed electrician visits your home and listens to your goals: for example, you want to add an EV charger, renovate the kitchen, or prepare for solar panels. The electrician performs a load calculation based on the size of the home, the number of major appliances, and future plans. If the calculation shows that 200 amp service is appropriate, they will design the upgrade.

Next, the electrician applies for an electrical permit from the Authority Having Jurisdiction (AHJ), which is usually your city or county building department. The permit makes sure that the work will be inspected and that it follows the NEC and local amendments.

Utility coordination and scheduling

Because the service entrance conductors and meter are involved, the utility company must disconnect power at the right time. In most places, the electrician contacts the utility in advance and schedules a day for the shutdown and reconnection. On that day, the power is turned off, the meter is removed, and the service cables are made safe so the electrician can work on the system.

Removing the old panel and preparing the new one

After the power is off, the electrician labels and carefully disconnects all the branch circuit wires from the old panel. The old panel is removed from the wall. If the service mast or meter base also needs to be upgraded to 200 amps, these parts are replaced or modified as needed, often using a 2‑inch conduit for the new service entrance conductors.

The new 200 amp panel is then mounted securely at the correct height and location, respecting the NEC working‑space rules (usually at least 30 inches wide and 36 inches clear space in front).

Installing new 200 amp service conductors

New 4/0 aluminum or 3/0 copper service entrance conductors are installed between the meter base and the main breaker in the panel. If aluminum conductors are used, an approved anti‑oxidant compound is applied to the conductor ends before securing them under the lugs. This reduces the risk of corrosion and heating over time.

Connecting branch circuits and torquing lugs

Next, all the existing branch circuit wires are re‑connected to the new breakers. Each conductor is placed under the correct terminal and tightened using a torque screwdriver or torque wrench to the exact value printed by the manufacturer. This torquing step is very important. Loose connections can create hot spots, arcing, and fires, even if everything looks fine from the outside.

Circuits are then clearly labeled on the panel directory, so future maintenance and troubleshooting is easy

Grounding and bonding upgrades

During a 200 amp upgrade, the electrician also checks and improves the grounding and bonding system. This may include:

- Installing two ground rods outside the building and connecting them with a bare copper grounding electrode conductor.

- Bonding the metal water pipe if present, within a certain distance of where it enters the house.

- Confirming that the neutral and ground are properly bonded in the main service panel and separated in any subpanels.

Inspection and re‑energizing the service

After the work is completed, the local electrical inspector visits the site, checks the panel, grounding, conductor sizes, and labeling, and confirms that everything follows the code. When the inspector is satisfied, they approve the installation. The utility then comes back to reinstall the meter and re‑energize the service. At this point, your house officially has a new 200 amp service.

Cost Overview – 200 Amp Service Upgrade (Chart and Table)

| Upgrade Scenario | Typical Cost Range (USD) | Notes |

| Basic panel replacement only | $1,500 – $3,000 | Minimal exterior work, existing meter and mast often reused. |

| Full 200A service upgrade | $3,000 – $6,000 | New meter base, service conductors, grounding, and permits. |

| Complex / custom projects | $6,000 – $10,000+ | Long runs, underground service, structural changes, or high local labor rates. |

Typical Cost Ranges for a 200 Amp Panel Upgrade

Homeowners often ask one question before anything else: “How much will it cost to upgrade to a 200 amp panel?” The honest answer is that it depends on several factors, but we can give realistic ranges to help you plan your budget.

Main factors that affect price

Several items have a big influence on the final cost:

- Scope of work: Is it just a panel replacement inside the house, or a full service upgrade including meter base, service mast, and new service entrance conductors? A full upgrade costs much more than a simple panel‑only replacement.

- Local labor rates: Electrician labor costs change a lot between regions and even between cities. In big metropolitan areas, hourly rates are usually higher than in small towns.

- Material choice: The price of the 200 amp panel itself, the size and price of conductors, the meter base, conduit, breakers (especially AFCI and GFCI types), and grounding materials all add to the total.

- Complexity: If the panel location must be moved, if walls need to be opened and repaired, if there is trenching for underground service, or if the existing wiring is in bad condition, the work becomes more complicated and expensive.

- Permits and utility fees: Permit costs vary by city, but they are always part of a legal upgrade. Some utilities also charge a fee for changing the service size.

Approximate cost ranges

While exact numbers change from year to year and region to region, we can give some general ranges that many homeowners see when upgrading to 200 amp service:

- Basic panel replacement with minimal outside work: around 1,500 to 3,000 USD in many markets.

- Full service upgrade with new meter base, new service entrance wiring, and grounding improvements: often 3,000 to 6,000 USD, and sometimes higher if conditions are complex.

In certain areas with high labor costs or special conditions, total prices above 8,000–10,000 USD are also possible, especially when the service entrance is long, underground, or requires coordination with other construction work.

Why a proper upgrade is worth the cost

At first glance, these numbers may look high, but remember that the electrical service is one of the most critical safety systems in your home. A cheap or unlicensed job can expose you to fire risk, failed inspections, or even denial of insurance claims after an incident. A properly designed and inspected 200 amp service upgrade, on the other hand, adds long‑term value and safety, and it is a strong selling point if you ever decide to sell the property.

Grounding, Bonding, and Safety Details You Should Know

Grounding and bonding are topics that many homeowners find confusing, but they are central to electrical safety. When you upgrade to a 200 amp panel, your electrician will closely check these systems.

Ground rods and grounding electrode conductor

For a 200 amp service, the NEC usually requires at least two ground rods driven into the earth, spaced a minimum distance apart (often 6 feet or more). A copper grounding electrode conductor runs from the main panel to these rods, creating a reference point between the electrical system and the earth. The size of this conductor is selected according to code tables and is typically #4 or #6 copper for many residential services.

Bonding the metal water pipe and other systems

If your home has a metal water piping system that enters from the ground, it must be bonded to the electrical system. A bonding jumper is connected from the panel to the pipe within a specified distance from where it enters the building. This ensures that the piping system and the electrical system are at the same electrical potential, reducing the risk of shock.

In some cases, gas piping, metal structural frames, or other conductive systems also need bonding according to code.

Neutral‑ground bond in main panel vs subpanel

The rule is simple but very important: in the main service panel, the neutral and ground are bonded together. In any downstream subpanel, neutrals and grounds must be kept separate. The neutral bus in the subpanel must be isolated from the metal enclosure, while the ground bar is bonded to the enclosure. The feeder cable to the subpanel must include a separate equipment grounding conductor.

This separation prevents normal neutral current from flowing on grounding paths, which could create shock hazards on metal parts that people touch.

Load Planning – EV & Solar Impact (Light Blue Chart and Table)

| Load Scenario | Approx. Continuous Load (A) | Comment |

| Base house (lights, plugs, appliances) | 60 – 90 A | Typical occupied home without EV charging or large new loads. |

| Base house + one Level 2 EV charger | 100 – 140 A | Panel still under 80% of 200A rating in many cases, if designed correctly. |

| Future EV + additional electrification | 140 – 160 A+ | Careful load calculation is needed to stay within safe continuous limits. |

Integrating EV Charging and Solar Power with a 200 Amp Panel

Another big reason many homeowners choose a 200 amp service upgrade is to prepare for electric vehicles and solar power systems. These technologies introduce special considerations for your electrical panel.

EV charger on a 200 amp panel

A Level 2 EV charger commonly uses a 40 amp or 50 amp breaker and may draw power for many hours at night. On a 100 amp service, adding such a charger can push the system close to or beyond its safe continuous limit, especially if other large loads run at the same time. With a 200 amp panel, there is much more comfortable headroom.

When planning for an EV charger, your electrician will check your load calculation again and ensure that the panel still respects the 80% rule for continuous loads. In some cases, a demand‑management system or smart charger may be recommended to limit how much current the EV charger can draw when other loads are active.

Solar photovoltaic systems and busbar limits

When you install a solar PV system, power can flow from the array into the panel through a backfeed breaker. This means power is coming from both the utility and the solar system at the same time. The NEC has specific rules about how much solar current can be connected to a panel without exceeding the busbar rating.

In a 200 amp panel with a 200 amp bus, the common rule (using the 120% rule, depending on the design) may limit how large a solar system you can connect before needing special arrangements like a supply‑side connection or a panel with a higher bus rating.

This is another advantage of planning ahead. If you know you will install solar within a few years, your electrician can choose a panel and design that make solar integration simpler and safer later.

Common Configurations: Main Panel, Subpanels, and Meter‑Main Combos

Modern homes do not always rely on a single electrical panel. There are several useful configurations that you might see when dealing with a 200 amp service.

200 amp main panel with subpanels

A typical arrangement is a 200 amp main breaker panel inside or near the main living area. From this panel, one or more feeders go to subpanels in other locations. For example, a 60 amp subpanel in a detached garage, or a 100 amp subpanel in a basement workshop or addition.

Using subpanels helps reduce long branch‑circuit runs, improves organization, and allows local shutdown of a specific area without affecting the whole house.

Feed‑through lugs

Some 200 amp panels include feed‑through lugs at the bottom. These are large terminals that allow the main conductors to continue on to another panel. In this way, a single service entrance can feed two panels, such as an indoor panel and a panel in a separate part of the building, without needing a separate meter or disconnect for each one.

Outdoor meter‑main combinations

In some regions, it is common to install a meter‑main combination outside the building. This outdoor unit includes the utility meter and a main breaker (often 200 amps) in one enclosure. From this meter‑main, feeder cables go to one or more indoor subpanels. This configuration can simplify inspection and utility access and may be required by local regulations.

Safety Rules, Compliance, and Good Habits

Working on a 200 amp service is dangerous and should never be done as a DIY experiment. There are several important reasons why this type of work is reserved for licensed professionals.

Licensed electricians only

A 200 amp breaker box, even when the main breaker is off, can still have live parts inside, especially at the main lugs where utility conductors land. These parts are energized whenever the meter is in place, and only the utility can make them safe. Professional electricians are trained to work with such hazards, use the right personal protective equipment, and follow strict lockout/tagout procedures.

Permits and inspections

Permits are not just “paperwork.” They are a formal process to ensure that the design and installation follow the NEC and local rules. After the work is done, an inspector reviews the installation, checks clearances, conductor sizes, breaker types, GFCI/AFCI locations, grounding, and labeling. An inspected and approved 200 amp panel gives confidence to you, to future buyers, and to insurance companies.

Correct torque on all terminations

It is very common to find loose lugs and terminals in older panels. When electrical connections are not torqued to the manufacturer’s specified value, they can loosen over time from thermal expansion and contraction. Loose connections produce heat, cause arcing, and can lead to fires. Modern codes and good practice require that all terminations in a new panel be tightened using torque tools and the printed torque values.

Matching wire size and breaker rating

Every breaker must protect a conductor of the correct size. For example, a 15 amp breaker normally protects 14 AWG copper wire, while a 20 amp breaker protects 12 AWG copper. Using a 30 amp breaker on a 14 AWG wire is extremely dangerous because the wire may overheat before the breaker trips. When upgrading your panel, the electrician will check that each existing circuit is matched to an appropriate breaker size.

Neutral and ground conductors on bus bars

Another detail that is often ignored in old panels is how neutrals and grounds are landed on the bus bars. In most modern panels, the manufacturer allows only one neutral wire under each screw on the neutral bar. Grounds, depending on the bar design, may sometimes be doubled under one screw, but only if the instructions permit it. A clean, correctly terminated bus bar layout is not just a matter of appearance; it directly affects safety and reliability.

Conclusion

A 200-amp panel upgrade isn’t just a bigger breaker box. It’s a long-term investment in safety, comfort, and future capacity for things like HVAC, EV charging, and solar (within code and busbar limits). If you’re seeing frequent trips, dimming lights, overheating, or corrosion, or you’re planning major electrical additions, talk to a qualified electrician for a load calculation and a clear written quote. This upgrade helps avoid overloaded-panel risks and prepares your home for the next decades.