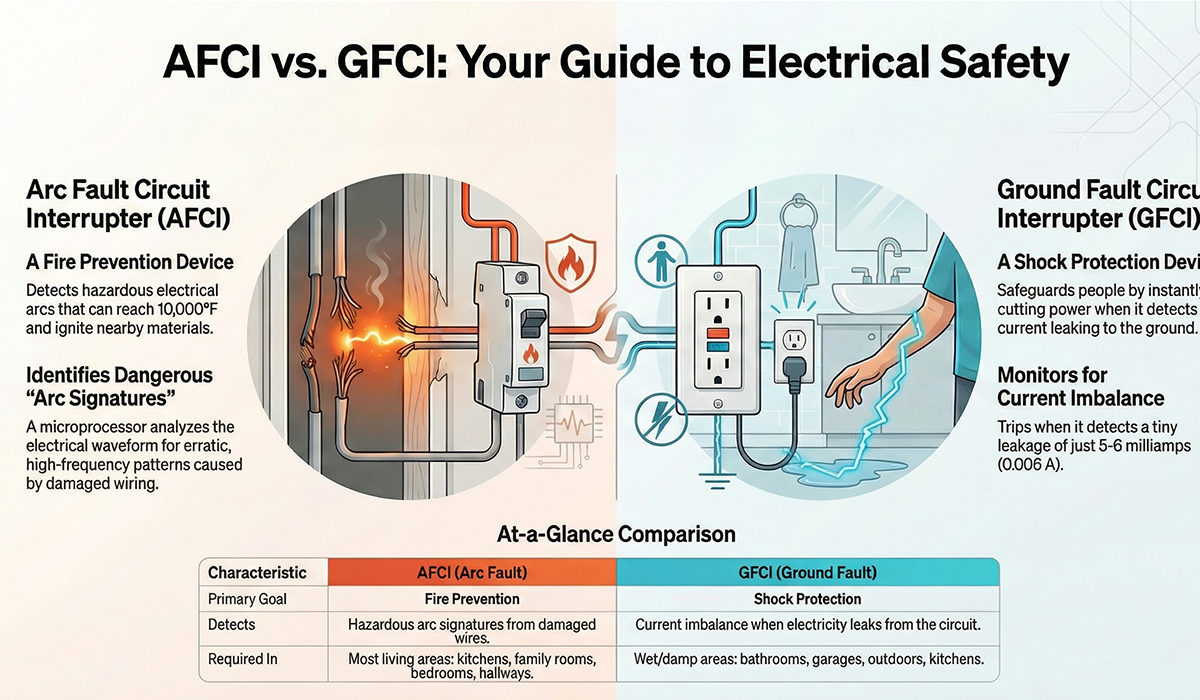

Although both AFCIs and GFCIs are specialized protective devices required by NEC, they are engineered to detect and reduce entirely different types of dangerous electrical conditions. Understanding this functional variance is necessary for correct specification and system wide protection.

Arc Fault Circuit Interrupters AFCIs are essentially fire prevention devices. Their central function is to proactively detect the unique electrical signatures of hazardous arched conditions. Such unwanted electrical sparks are caused by issues like damaged insulation, loose connections in outlets or fixtures, or compromised wiring within walls, pierced by a nail or screw. A dangerous arc can generate intense, localized heat up to 10,000 degrees Fahrenheit, capable of instantly igniting surrounding combustible materials such as wire insulation or wood framing.

Ground Fault Circuit Interrupters (GFCIs)

GFCIs are designed specifically for shock protection. They work by monitoring the balance of electrical current between the hot (line) conductor and the neutral conductor. If the current going out is different from what is coming back by a minute leakage-as little as 5 to 6 milliamps, or 0.006 amps-the GFCI detects a ground fault, meaning current is leaking from the circuit, possibly through a person who has become an unintended path to ground. The device quickly cuts off power to prevent lethal electric shock.

GFCI protection is required in areas where human contact with energized circuits in wet or damp conditions is likely to occur and is generally found in bathrooms, garages, kitchens, laundry areas, unfinished basements, and outdoor locations.

Mechanism of Protection: How AFCI Technology Detects Dangerous Arcs

Modern AFCI employs advanced microprocessor technology to constantly monitor the waveform of the current. An arc fault produces a distinctive, erratic, and noisy waveform signature quite unlike normal flowing electricity.

The AFCI circuitry uses sophisticated digital signal processing to distinguish between safe, normal arcs-such as those created when a switch is flipped or a motor operates-and dangerous, sustained arcs. These dangerous signatures typically consist of electrical current oscillating at characteristic high frequencies, around 100 kHz, persisting for longer than several milliseconds. Once this signature has been identified, the AFCI acts to trip internal contacts, thereby de-energizing the circuit in a very short period of time to avoid ignition.

Types of Arc Faults: Series vs. Parallel Arcs To provide complete protection, new AFCIs must detect two main classes of hazardous arcing conditions

Parallel Arc Faults (Line-to-Neutral or Line-to-Ground):

Description: This is the more dramatic type, in which current jumps between the hot conductor and the neutral or ground conductor. It often results from physical damage, such as a nail piercing two conductors or severely damaged insulation.

Current Flow: The current in a parallel arc does not flow through the electrical load, therefore it is not current limited by appliances. The resulting current can be very high, limited only by the wire resistance and source impedance, leading to rapid, catastrophic failure and immediate high heat.

Parallel Arc Faults (Line-to-Neutral or Line-to-Ground)

Description: This is the more dramatic type, in which current jumps between the hot conductor and the neutral or ground conductor. It often results from physical damage, such as a nail piercing two conductors or severely damaged insulation.

Current Flow: The current in a parallel arc does not flow through the electrical load, therefore it is not current limited by appliances. The resulting current can be very high, limited only by the wire resistance and source impedance, leading to rapid, catastrophic failure and immediate high heat.

Series Arc Faults

Description: This takes place when an arc forms along the path of a single conductor, such as a loose terminal screw, frayed wire, or incomplete break in a conductor.

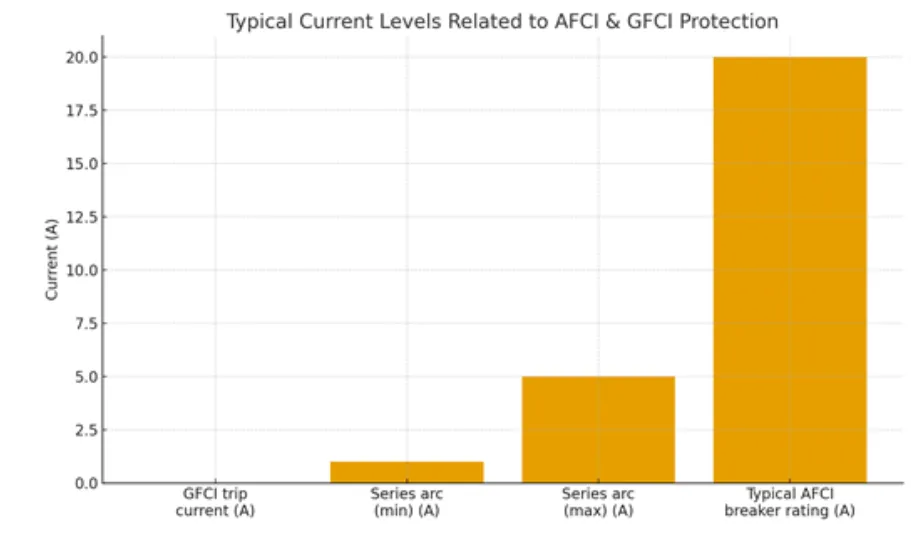

Current Flow: Since the arc is “in series” with the load, the fault current is limited by the connected devices. In other words, series arc currents are usually considerably lower (often 1 to 5 amps) and normally cannot be detected by standard circuit breakers that trip only on high overcurrent. Series arcs do produce significant, continuous heat, though, which can slowly destroy insulation and often lead to a far more destructive parallel arc fault after some time. The superior “Combination AFCI” is specifically required to detect both series and parallel arc faults.

Decoding AFCI Types and Functionality

It was the NEC that drove the evolution of AFCI devices to ensure greater protection across the entire circuit.Branch/feeder AFCI: An older-generation AFCI primarily detecting parallel arc faults between conductors. The protection it offers against series faults is limited; it is, for the most part, superseded by newer technology in new installations.

Combination AFCI (CAFCI): Combination arc fault circuit interrupters have been a requirement since the 2005 NEC cycle. A CAFCI protects against both series and parallel arc faults. Presently, this is the minimum requirement for most new branch circuit installations.

Outlet Branch-Circuit AFCI: This is a receptacle-type device installed at the outlet and provides series arc protection for the wiring downstream of the device and parallel arc protection beginning at the receptacle. When applied with a Branch/Feeder-type breaker, it may satisfy NEC requirements for circuit protection.

Dual-function AFCI/GFCI breakers: Sometimes called “super breakers,” these single devices incorporate a full combination AFCI protection along with the GFCI ground-fault protection in one device. They provide a highly efficient and compliant solution to circuits needing the protection of both, which include the ones supplying the receptacles in kitchens, laundry areas, or unfinished basements.

To gain a more comprehensive understanding of electrical panels and their various types, as well as how they play a crucial role in electrical safety and circuit protection, we highly recommend exploring this detailed guide on all types of electrical panels. This guide covers essential information about different panel configurations, including the necessary safety protocols and standards for proper installation.

Navigating NEC Requirements: Where AFCI and GFCI Are Required

The National Electrical Code continuously updates and adds requirements for the use of safety devices to improve protection in residences.

AFCI Requirements (NEC Article 210.12)

AFCI protection is required for all 120-volt, single-phase, 15- and 20-amp branch circuits supplying outlets or devices installed in nearly all living areas of a dwelling unit. This includes:

Living Spaces: kitchens, family rooms, living rooms, dining rooms, parlors, libraries, dens, and recreation rooms.

Sleeping/Service Areas: Bedrooms, sun rooms, closets, hallways and laundry areas. Note that the requirement is for the entire branch circuit supplying these areas, so protection extends to receptacles, permanent light fixtures (luminaires), and hardwired smoke detectors. The 2023 NEC has reorganized these requirements for clarity in Section 210.12(B).

GFCI Requirements (NEC Article 210.8)

GFCI protection shall be provided for all 125-volt, single-phase, 15- and 20-ampere receptacles installed in locations that are subject to a wet environment where the likelihood of shock is increased:

Bathrooms and garages

Outdoors and Crawl Spaces.

Figure 1 – Typical current levels associated with AFCI and GFCI protection, based on NEC-related values from this article.

| Parameter | AFCI (Arc Fault Circuit Interrupter) | GFCI (Ground Fault Circuit Interrupter) |

| Primary protection purpose | Fire prevention by detecting dangerous arc faults caused by damaged insulation, loose connections, or compromised wiring that can reach up to 10,000 °F. | Shock protection by detecting ground-fault leakage current and disconnecting the circuit. |

| Detection principle / thresholds | Microprocessor-based waveform monitoring to identify high-frequency arc signatures (around 100 kHz) that persist for several milliseconds. | Monitors imbalance between hot and neutral; trips when a leakage of about 5–6 mA (0.006 A) is detected. |

| Typical NEC branch-circuit ratings | Required on 120 V, single-phase, 15- and 20-A branch circuits supplying outlets and devices in most dwelling unit living areas. | Required on 125 V, single-phase, 15- and 20-A receptacles in locations with wet or damp conditions (bathrooms, garages, kitchens, laundry areas, basements, outdoors). |

| Device types mentioned | Branch/Feeder AFCI, Combination AFCI (CAFCI), Outlet Branch-Circuit AFCI, Dual-function AFCI/GFCI breakers. | GFCI receptacles and breakers, and dual-function AFCI/GFCI breakers used where both arc-fault and ground-fault protection are needed. |

| Typical installation locations | Living rooms, family rooms, dining rooms, parlors, libraries, dens, recreation rooms, bedrooms, sun rooms, closets, hallways, and laundry areas. | Bathrooms, garages, outdoors, crawl spaces, finished and unfinished basements, kitchens (including receptacles within 6 ft of sinks), and laundry areas. |

Table 1 – Summary comparison of AFCI and GFCI functions and NEC application requirements, taken from this article.

Basements-Finished and Unfinished.

Kitchens – all receptacles and around sinks – within 6 ft.

Laundry Areas.

Compliance in Remodeling and Extensions The NEC also requires AFCI protection for extensions, modifications, or replacements of branch circuit wiring in the involved areas of existing homes. Where replacements of receptacles are installed in dwelling units, AFCI protection must be provided by one of several listed means; this most frequently involves either a combination-type AFCI breaker or a listed outlet branch-circuit-type AFCI receptacle. Always consult the local AHJ as requirements may differ.

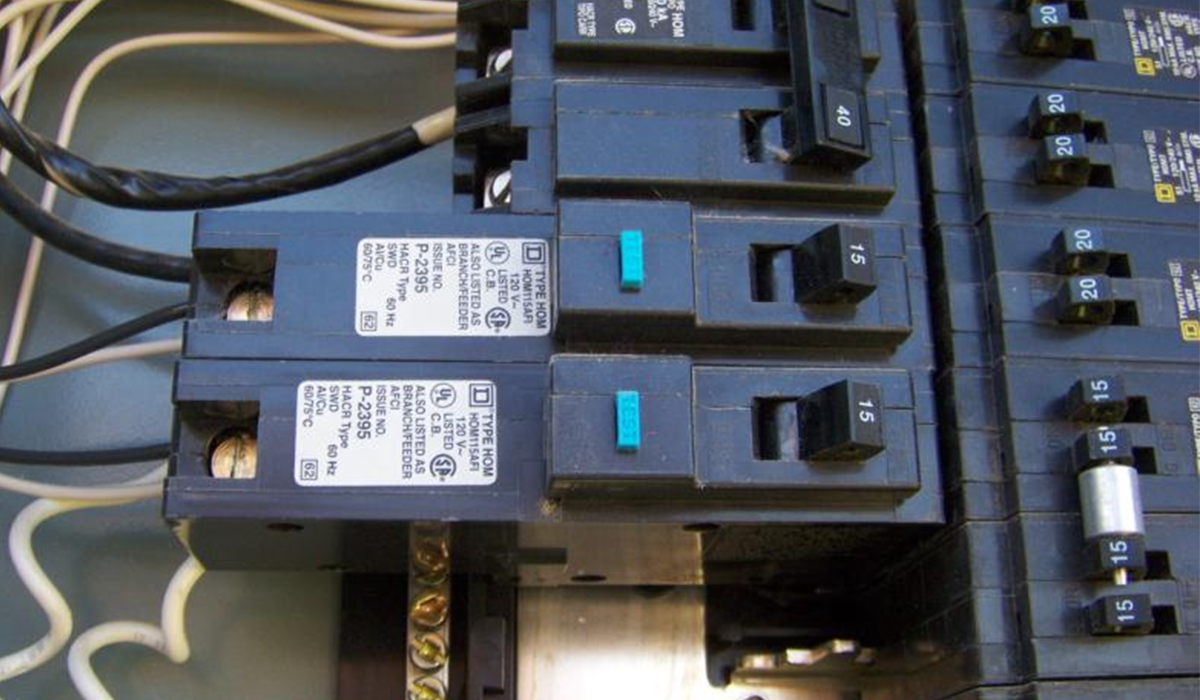

Installation Best Practices: Pigtail vs. Plug-On Neutral Designs

The physical installation of AFCI and CAFCI circuit breakers in the main panel generally involves one of two modern technologies.

Pigtail Style

This is traditionally done where a white pigtail wire extends from the circuit breaker body.

The pigtail wire from the breaker is directly connected to a neutral bar in the panel.

The hot line wire of the circuit connects to the gold terminal of the breaker, while the load neutral wire of the circuit connects to the silver terminal of the breaker.

Pro Tip: This style can increase wire congestion inside the panel because of the additional pigtail connection.

Plug-On Neutral Style

This is the preferred modern installation method, and it simplifies the wiring process.

The design eliminates the pigtail wire, replacing it with a conductive metal clip on the back of the breaker to make the neutral connection automatically when the device is “rocked” or “popped” onto the designated neutral bar of a compatible panel. The hot and neutral wires of the circuit connect directly to the breaker’s terminals. Benefit: This method reduces clutter and limits the number of conductors that must be routed inside the panel, thus accommodating a neater and easier installation.

Common causes of nuisance tripping

Wiring errors: This includes loose connections and the critical error of mixing neutrals from different circuits-known also as shared neutrals-especially in multi-wire branch circuits. If a MWBC has a shared neutral, it requires a two-pole AFCI circuit breaker.

Incompatible Devices: Some electrical devices create electrical “noise” or current characteristics that can emulate the high-frequency signature of a real arc fault. Examples include some vacuum cleaners, older motors, and certain laser printers.

External Interference: AFCIs can be sensitive to voltage profiles similar to arc faults that may be induced by lightning strikes. They are also known to be sensitive to radio frequency energy, specifically within the High Frequency spectrum from 3–30 MHz used by shortwave broadcasting and amateur radio.

Professional Steps in Troubleshooting

As a professional engineer, I recommend a rigorous step-by-step diagnostic process:

Systematic Inspection: Visually check for physical damage such as pinched cords and blackened outlets.

Check torque and connections: Before energizing the panel, ensure that all connections are tightened to the manufacturer’s specification torque values, specifically at the breaker and the first outlet. Verify that the load neutral is connected properly to the breaker and also the pigtail if used to the neutral bar.

Load Isolation: Unplug all devices and appliances from the circuit. Reset the breaker. If the breaker holds, plug in one device at a time to isolate the source of the trip.

Mitigation: In the case of electrical noise, suggest surge protectors that will do a fine job of filtering out unwanted electric noise or, in extreme measures, the application of ferrite chokes on sensitive loads.

Global Context: AFCIs and the AFDD Standard

In international context, especially in regions adhering to IEC standards, this technology is more commonly referred to as an Arc Fault Detection Device, or AFDD.

AFDDs play the same crucial role as AFCIs in fire prevention through the detection of dangerous arcs. In many global markets, including parts of Europe and the UK, the standard governing these devices is IEC 62606. While implementation may vary, the basic aim remains the same: harnessing advanced digital waveform analysis for improved fire safety in electrical installations.

https://shorturl.fm/48bdf