What is a busbar cutter?

A busbar cutting machine (also called a busbar cutter or busbar cutting tool) cuts copper or aluminum busbars to length. In many shops it is part of a 3‑in‑1 station (punching, bending, cutting). For clean, safe work, we want straight, burr‑free edges and correct length every time.

Copper vs. aluminum cutting

Copper C110 is stronger and more ductile than aluminum 6101‑T6. It will usually take more force and a tighter blade setting. Aluminum will cut with less force but can smear if the blade isn’t sharp. Always set blade clearance for the material to reduce burrs and distortion.

Cutting technologies compared

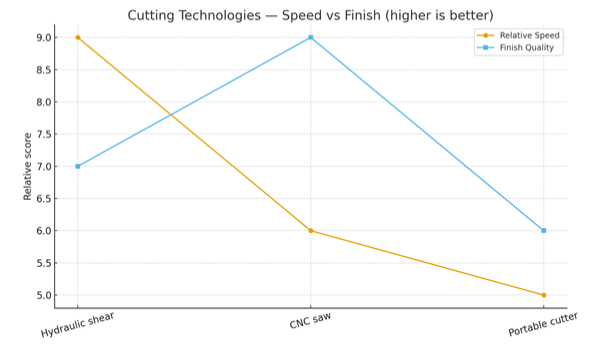

Quick Reference — Cutting Technologies

| Technology | Best for | Finish | Speed | Notes |

| Hydraulic guillotine shear | Shop cutting of short‑to‑medium parts | Burr‑free with correct blade clearance | Very fast | Low deformation; check blade clearance and backgauge stop |

| CNC saw cutting line | Premium finish and tight tolerance parts | Excellent, flat face | Slower; chips to manage | Minimal deformation; needs chip collection and guarding |

| Portable hydraulic cutter | Field / MRO jobs and on‑site fixes | Depends on tool and blade condition | Moderate | Verify pump/hose compatibility; confirm capacity before use |

Figure: Relative speed and finish for common busbar cutting methods.

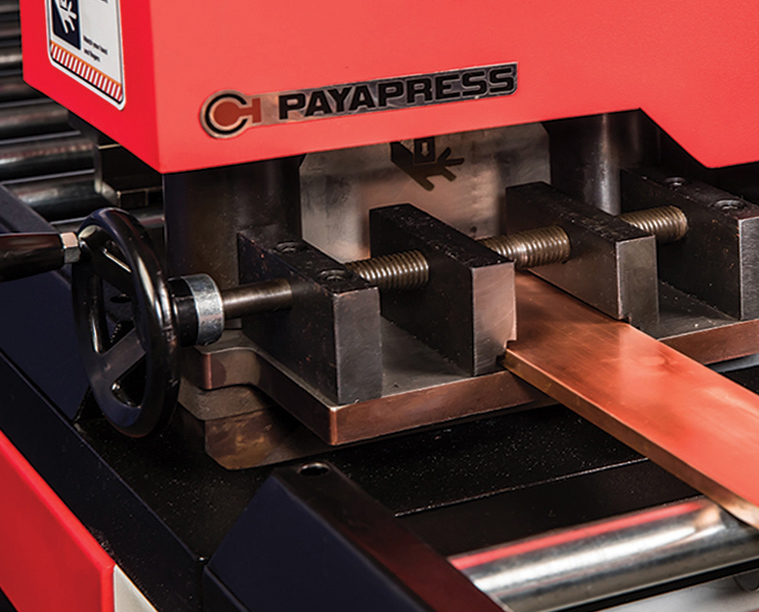

Hydraulic guillotine shear

Most common in shops. A hydraulic busbar cutter uses a straight or V‑blade. We close the guard, clamp the bar, and shear. Good machines target burr‑free cutting, with guides and a backgauge/stopper to control length.

V‑blade vs. straight blade

A V‑blade focuses force and can reduce bowing on thick bars, but may mark the edge more. A straight blade spreads force and can give a flatter face, but needs correct clearance to avoid rollover. Choose based on your typical material and finish needs.

CNC saw cutting lines

A CNC busbar cutting machine with a saw gives high accuracy and very good finish. It is slower than shearing for short pieces, creates chips, and needs chip collection, but it can minimize deformation (good for tight assemblies).

Portable hydraulic cutters

For field/MRO work, a portable cutter with an electro‑hydraulic pump is useful. Check the hose/pump compatibility and the maximum capacity before use.

Capacity & tonnage sizing

Do not under‑size the machine. A common shop target is 125×13 mm (≈ 0.5″×5″). Cutting force depends on alloy and thickness. Ask for a clear ‘tonnage calculation for cutting’ from the vendor. Higher force is needed for copper than aluminum. Use ASTM B187 and B209 material data when available.

Blade clearance & setup

Correct blade clearance is key for burr‑free cutting. Too tight can gall the edge; too wide makes rollover and big burrs. Verify clearance after blade changes. Keep a written setup checklist and do a test cut before production.

Workholding & support stands

Use a straight backgauge or stopper for repeat length. Support long bars with stands so the bar stays level and the cut stays square. This also protects the operator.

Tolerance & surface finish

Agree on a practical cut tolerance with your team (for example, ±0.5–1.0 mm for many LV parts—your design may need tighter). Always deburr after cutting to protect insulation and to reduce joint resistance. Keep a simple edge‑deburring workflow and replace blades when edges lose quality.

Safety & compliance (U.S.)

Follow OSHA 1910 machine‑guarding rules. Use safety interlock guards, emergency‑stop, and clear LOTO steps. Wear PPE (gloves, eye/face protection, hearing protection for saw lines). For assemblies, respect UL 891 and NFPA 70 (NEC). IEC 61439 practices are also helpful for global projects.

“Follow OSHA 1910 machine‑guarding rules. Use safety interlock guards, emergency‑stop, and clear LOTO steps. Wear PPE (gloves, eye/face protection, hearing protection for saw lines). For assemblies, respect UL 891 and NFPA 70 (NEC). IEC 61439 practices are also helpful for global projects, especially when considering safety busbar requirements

Pricing & cost factors (USA)

Price changes with capacity (tonnage), automation (manual vs CNC), blade set (V or straight), guarding, pump, and freight. Look at total cost of ownership (TCO): blades and sharpening, hydraulic oil and hoses, downtime, training, and safety checks. A CNC busbar cutting machine costs more at the start but can save time and reduce scrap.

Ownership costs (TCO)

Plan a small annual budget for replacement blades, oil/filter changes, leak checks, and calibration. Keep a maintenance log so you can predict blade changes before quality drops.

Installation & maintenance

Place the cutter on a level floor with safe access. Match the hydraulic pump and hoses to the cutter. Do daily cleaning, leak checks, blade inspection, and backgauge calibration. Train operators and keep clear SOPs near the machine.

Real‑world use cases

In a switchgear/MCC/panelboard shop, a simple line is: cut → deburr → punch/bend → inspect. Keep long bars on supports to protect workers and accuracy.

For a deeper dive into U.S. safety requirements that affect busbar cutting operations—especially machine guarding, PPE, and lockout/tagout—consult the official OSHA 1910 machine guarding guidance. Aligning your cutter setup and procedures with these standards (alongside UL 891/NFPA 70 practices for assemblies) helps ensure compliant, low-risk production while maintaining consistent cut quality.

Selection checklist

- Material & size: What bar sizes do you cut most (e.g., up to 125×13 mm / 0.5″×5″)? Copper vs aluminum?

- Finish: Do you need burr‑free edges from the machine or is post‑deburr OK?

- Throughput: Pieces per shift now and in 12–24 months.

- Accuracy control: Backgauge, stops, or CNC positioning?

Safety: Interlock guards, E-stop, LOTO procedure, PPE policy. - Compliance: OSHA 1910, UL 891/NFPA 70; follow practice according to IEC 61439.

- Budget & TCO: Automation/capacity presently versus cost of blades/pumps/maintenance.