In today’s competitive manufacturing landscape, precision, speed, and efficiency are more important than ever. Whether it’s sheet metal corner forming, CNC corner forming, or even more specialized tasks like corner former processes, manufacturers continuously seek ways to enhance their operations. One of the most valuable tools in this pursuit is the corner forming machine.

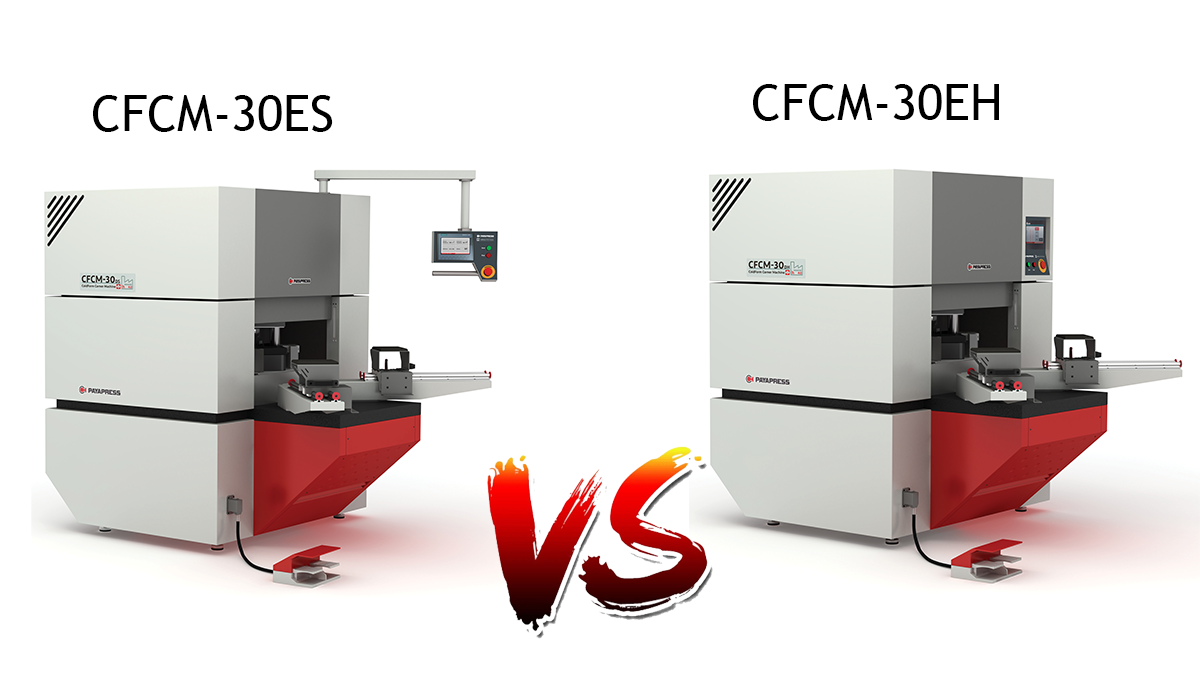

Payapress provides two versions of this machine—the CFCM-30EH and the CFCM-30ES each designed to meet the demands of different production scales. These machines are built to streamline the corner forming process in sheet metal fabrication, offering manufacturers the ability to produce high-quality, precise components with minimal effort and material waste. In this article, we’ll explore the features, benefits, and applications of both models, illustrating how the corner forming machine is transforming industries worldwide.

What is a Corner Forming Machine?

A corner forming machine is a specialized tool used in the fabrication of sheet metal to perform essential tasks such as bending, cutting, and forming precise corners in metal sheets. These machines are crucial for producing clean, accurate, and repeatable bends in materials like aluminum, copper, and steel. These materials are widely used in industries such as electrical panel manufacturing, automotive production, and construction.

By automating the corner forming process, these machines not only reduce production time but also minimize the margin of error commonly associated with manual methods. The CNC corner forming machine provides even more sophisticated features, such as programmable controls, allowing for greater precision and efficiency when working with complex geometries. This makes it an essential tool for modern manufacturing operations that require both speed and accuracy.

Two Versions of Payapress Corner Forming Machines

Payapress offers two distinct models of the corner forming machine, designed to meet varying industry needs. These models are the CFCM-30EH and CFCM-30ES.

CFCM-30EH: High-Speed Performance

The CFCM-30EH is designed for manufacturers who require high throughput and reliable performance. Capable of processing sheet metal up to 120mm x 12mm, the CFCM-30EH is equipped with three independent power packs, allowing the machine to operate across all stations (bending, punching, and cutting) simultaneously. This feature makes the CFCM-30EH ideal for high-volume production environments, where speed and precision are essential.

Key Features:

High-speed production with multiple stations working simultaneously

Perfect for standard corner forming tasks

Reliable performance in large-scale manufacturing environments

Capable of handling up to 120mm x 12mm sheet metal

CFCM-30ES: Advanced Precision and Customization

The CFCM-30ES offers a higher level of control and precision, making it suitable for industries requiring highly customized corner shapes and more intricate metalworking processes. This model features a digital angle indicator and an elastic return compensation system, ensuring that every corner is perfectly formed, even when working with thicker materials or more complex designs.

Key Features:

Ideal for intricate and custom corner forming tasks

Suited for thicker materials and complex geometries

Includes digital angle indicators and elastic return compensation

Perfect for industries requiring precision and customization

Both models offer distinct advantages depending on the specific needs of your production process. The CFCM-30EH is great for high-speed, high-volume production, while the CFCM-30ES excels in precision and flexibility for more specialized tasks.

Comparison of Payapress Corner Forming Machines: CFCM-30EH vs. CFCM-30ES

The CFCM-30EH and CFCM-30ES models from Payapress are designed to meet the diverse needs of industries requiring precision in sheet metal corner forming. In the following table, you can see a detailed comparison of both models, showcasing their unique features, applications, and capabilities to help you choose the best machine for your production requirements.

| Features | CFCM-30EH | CFCM-30ES |

|---|---|---|

| Production Speed | High-speed production with multiple stations working simultaneously | High precision, ideal for complex designs and customization |

| Material Compatibility | Aluminum, Copper, Steel | Aluminum, Copper, Steel |

| Special Features | Three independent power packs, simultaneous operation (bending, punching, and cutting) | Digital angle indicator, elastic return compensation system |

| Best For | High-speed, high-volume production | Custom production and high precision requirements |

| Maximum Sheet Size | 120mm x 12mm | 120mm x 12mm |

| Power Packs | 3 Independent Power Packs | 2 Independent Power Packs |

| Precision | Standard Corner Forming | Advanced Precision and Customization |

| Customization | Limited customization options | Advanced customization for intricate shapes |

| Applications | Ideal for electrical panel manufacturing, automotive, and general sheet metal work | Ideal for aerospace, automotive, and high-precision metalworking industries |

| Weight | 1200 kg | 1200 kg |

| Hydraulic Force | 200 bar | 200 bar |

| Motor Power | Electrogen 1 x 4 kW | Electrogen 1 x 4 kW |

| Hydraulic Tank Capacity | 50 Litre | 50 Litre |

| PLC | Delta | Delta |

| Control Codes | Raad | Autonics |

| Sensor | Autonics | Autonics |

How Does the Corner Forming Machine Benefit the Industry?

The corner forming machine offers several advantages that have made it indispensable in modern sheet metal manufacturing. Not only does it reduce the need for manual labor, but it also significantly improves the quality, speed, and efficiency of the production process.

Precision and Consistency

The automation of the corner forming machine ensures that each corner is formed with high precision, minimizing the risk of human error. This is especially important in industries where exact measurements and repeatability are critical, such as electrical panel manufacturing. With these machines, manufacturers can rely on consistent results, ensuring high-quality products with every batch.

Speed and Efficiency

By combining bending, cutting, and punching in a single unit, the corner forming machine dramatically reduces production times. The CFCM-30EH excels in high-speed production, while the CFCM-30ES offers enhanced precision and flexibility, making both machines suitable for various production environments. This combination of speed and efficiency ensures that your manufacturing processes remain competitive in today’s fast-paced industrial landscape.

Cost Savings

By reducing material waste and minimizing the need for manual labor, the corner forming machine leads to significant cost savings. The accuracy of these machines ensures that there is minimal scrap metal, which translates to lower material costs. Moreover, the automation of the process reduces labor expenses, allowing manufacturers to improve their bottom line while maintaining high product quality.

Real-World Applications

The corner forming machine is used across multiple industries. Below are just a few examples of how these machines are making an impact.

Electrical Panel Manufacturing

In electrical panel manufacturing, precise sheet metal corner forming is required to ensure structural integrity and proper fitment of components. The corner forming machine automates this process, helping manufacturers achieve consistent results that meet strict safety and quality standards.

Automotive Industry

The automotive industry relies on precise metal components, such as brackets, reinforcements, and panels. The corner forming machine ensures that these parts are consistently produced with the exact specifications required for high-performance standards.

Construction and Architecture

In construction, custom metal components for building facades, structural elements, and HVAC systems often need precise corner forming. The corner forming machine helps create accurate, clean corners in aluminum and copper, making it an essential tool for contractors and architects who require customized metal solutions.

HVAC Industry

The HVAC industry benefits from the use of the corner forming machine for producing custom sheet metal ducts and components. These machines ensure high efficiency in production while maintaining the necessary precision for proper fitting and function in HVAC systems.

Aerospace Industry

In the aerospace industry, precision is crucial, particularly in the production of parts that need to fit together perfectly under extreme conditions. The corner forming machine ensures that these parts are manufactured with exact dimensions and minimal tolerance, which is vital for both safety and performance.

Conclusion

The corner forming machine is revolutionizing sheet metal processing. With advanced capabilities, both the CFCM-30EH and CFCM-30ES models provide essential solutions for manufacturers looking to streamline production while maintaining precision. Whether you need a high-speed, high-volume solution or a customized, precision-driven machine, the corner forming machine offers the flexibility and efficiency needed to stay competitive in today’s fast-paced industrial environment.

Industries worldwide are incorporating this technology to enhance their manufacturing processes, reduce costs, and achieve higher levels of product quality. If you’re looking to optimize your sheet metal fabrication process, investing in a corner forming machine could be the next step in achieving greater efficiency and precision.