The IEC 61439 Standards forms the basis of modern electrical assembly designs and certification.

Adopted as EN 61439 in Europe, this standard specifies the performances, safety, and verification requirements that ensure:

Within the context of the presents documents, low-voltage switchgear and control gear assemblies are designed to withstand real life conditions without compromising operator safety or system reliability.

IEC 61439 replaced the tradition standard IEC 60439 and brings clearness on responsibilities, specifically separating the roles between original manufacturer If applicable, this involves the design manufacturer, responsible for designs verification, and the Assembly Manufacturer, responsible for routine verification.

It provides a harmonized route to CE compliance under the low voltage directive (2014/35/ EU) and the EMC Directive (2014/30/ EU), It forms the technical backbone of conformity assessment and CE marking in the EU market.

source

Scope of IEC 61439 and Its Application in the EU

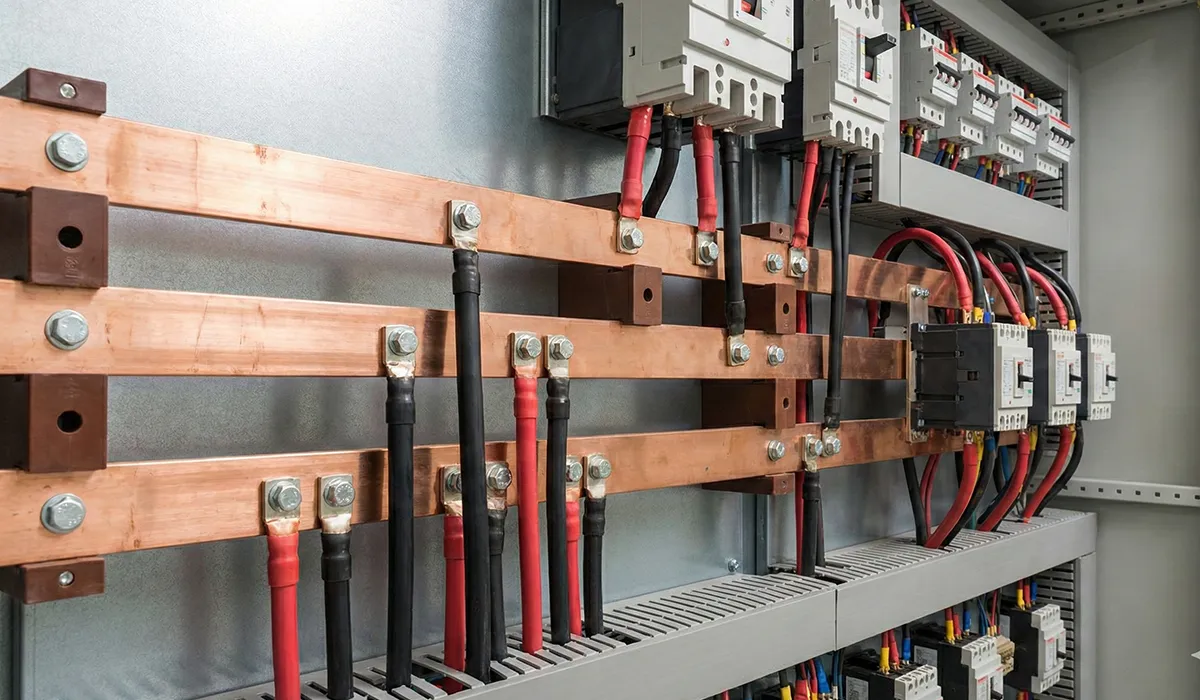

IEC 61439 governs low voltage switchgear and control gear assemblies (PSC assemblies), typically up to 1000 V AC or 1500 V DC.

These assemblies form the heart of modern power distribution in commercials, industrial, and General applications.

This standards ensures that every assembly, whether factory built or custom engineered meets crucial performance and safety standards.

The IEC 61439 standards series is Organized into several main parts:

• IEC 61439-1- General Rules: defines fundamental requirements applicable to all assembly types.

• IEC 61439-2- Power Switchgear and Control gear Assemblies: Specifies power distribution systems, motor control centers, and switchboards.

• IEC 61439-6- Busbar trunking Systems: Covers trunking, joints, and tap-offs, emphasizing mechanical and heated endurance.

Assemblies may be at rest or mobile,closed or open type, designed for indoor or outdoor use. Each configuration must fulfill

both electrical and environmental performance criteria. The standard defines how to manage current flow, insulation distances,

and environmental protection, ensuring safe operation throughout the lifecycle of the equipment.

Design verification methods under IEC 61439 standard

Design Verification— outlined in IEC 61439-1:2021, Clause 10— is the cornerstone of the standard.

It ensures that the design, components, and construction of the assembly upstand with all applicable safety and performance criteria

before any manufacturing begins. IEC 61439 introduces three equally valid verification methods:

1. Verification by Testing: Direct physical testing of representative assemblies under controlled conditions.

2. Verification by Comparison with a Reference Design: Demonstrating compliance by referencing a similar, previously tested design.

3. Verification by Assessment (Calculation/Measurement): Using standardized calculations and design rules to verify performance.

This tripartite approach replaces the old distinction between Type Tested Assemblies (TTA) and Partially Type Tested Assemblies (PTTA).

By removing ambiguity, IEC 61439 promotes flexibility while maintaining strict accountability for the design’s conformity.

Constructional and Performance Characteristics (Clause 10.2 & 10.3)

Design verification must address both constructional (Clause 10.2) and performance (Clause 10.3) characteristics of the assembly.

The table below summarizes the critical categories to verify:

Construction (Clause 10.2) | Performance (Clause 10.3)

—————————————— | ————————————–

Strength of materials and parts | Dielectric properties

Degree of protection (IP rating) | Temperature-rise limits

Creepage and clearance distances | Short-circuit withstand strength

Protection against electric shock | Electromagnetic compatibility (EMC)

Incorporation of switching devices | Mechanical operation

Internal wiring and connections | —

Terminals for external conductors | —

Each verified property must be backed by either a test report, calculation sheet, or documented comparison analysis.

These records form part of the Technical File for CE marking and are essential for legal compliance and traceability.

source

Temperature-Rise Verification and the Rated Diversity Factor (RDF)

Thermal management ensures assemblies operate within safe temperature limits (IEC 61439-1:2021, Clause 10.10).

Excessive heat can degrade insulation, accelerate aging, and lead to fire hazards. The temperature-rise test or calculation confirms

that under rated current conditions, all parts—including busbars, terminals, and devices—stay below the limits in Table 6 of the standard.

The Rated Diversity Factor (RDF) recognizes that not all outgoing circuits are loaded simultaneously.

For instance, if a distribution panel contains 10 feeders rated at 100 A each, it’s unrealistic to assume all draw full current at once.

Applying an RDF (say 0.7) allows thermal calculations that reflect realistic operational diversity. This improves efficiency,

avoids oversizing, and aligns with safe design principles.

Short-Circuit Withstand Verification (Clauses 10.11 & 10.12)

An assembly’s ability to withstand short-circuit stresses defines its robustness under fault conditions.

IEC 61439 requires verification of both thermal and dynamic stability during faults, expressed by three key parameters:

• Icw – Rated short-time withstand current (thermal stability, 1s or 3s duration).

• Ipk – Rated peak withstand current (mechanical forces during first half cycle).

• Icc – Conditional short-circuit current (with coordination by SCPDs).

Verification can be achieved by direct testing, by validated comparison with a reference assembly, or by analytical assessment

supported by manufacturer data (IEC 61439-1:2021, Clause 10.11.2). Conditional short-circuit testing (Icc) is common for assemblies

protected by current-limiting circuit breakers or fuses, ensuring safety without destructive testing of every model.

https://www.vde-verlag.de/iec-normen/218877/iec-61439-6-2012.html

Dielectric Properties and Ingress Protection (Clauses 10.9 & 10.2.2)

Note — The matrix is a practical summary. Always pair it with your detailed FAT template and the Design Verification dossier (IEC 61439-1:2021, Clauses 10 & 11).

Figure — Illustrative Temperature-Rise vs Current with RDF (IEC 61439-1:2021, Cl. 10.10). Values are conceptual for communication; verify designs with calculation, comparison, or testing.

| Characteristic | Clause (IEC 61439-1:2021) | Verification at FAT | Evidence to File |

| Continuity of Protective Circuits | 11.3 | Inject ≥10 A; ≤0.1 Ω to PE | Logged values; instrument ID; ambient |

| Clearances & Creepage (Visual) | 11.5 / 10.4 | Measure vs drawings; PD/CTI noted | Marked drawings; checklist; photos |

| Internal Wiring & Connections | 11.6 | Conductor size/route; torque per spec | Torque sheet; tool calibration |

| Terminals for External Conductors | 11.7 | Type/marking; space & access | Terminal schedule; photos |

| Mechanical Operation | 11.8 | Doors, interlocks, withdrawables | Function record; sign-off |

This central insert provides two practical artifacts for engineers: (1) a conceptual temperature-rise chart illustrating the impact of Rated Diversity Factor (RDF), and (2) a concise routine verification matrix aligned with IEC 61439-1:2021, Clause 11. Use them to brief design teams and to structure FAT documentation; for conformity, rely on validated tests or calculations.

leitfaden_IEC_EN61439_en.pdf

Performance Snapshot: Temperature-Rise & Routine Verification

Dielectric verification confirms that insulation systems can withstand operational voltages and overvoltages.

The power-frequency withstand test (typically 1.5–2.5 kV for 1s) checks for dielectric breakdown between live parts

and earth (IEC 61439-1:2021, Clause 10.9.2). Complementary insulation resistance tests identify contamination or assembly errors.

Ingress Protection (IP), tested per IEC 60529, ensures the enclosure resists dust and water.

For indoor switchboards, IP54–IP55 is typical; outdoor installations may require IP65 or higher.

Fans and filters, if fitted, must operate during IP tests, and failure is defined by any contact of water or dust with live components.

Creepage and Clearance Distances (IEC 60664-1 Reference)

Electrical safety relies on maintaining adequate insulation distances. IEC 60664-1 defines two critical parameters:

• Clearance – the shortest air distance between two conductive parts at different potentials.

• Creepage – the shortest distance along the insulating surface between two conductive parts.

For example, a switchboard rated for 8 kV impulse voltage must maintain a minimum clearance of 8 mm.

Creepage distances depend on pollution degree and material group, ensuring resistance to tracking and flashover.

Verification may be performed by test or visual measurement, but clearances exceeding 1.5 times the minimum value do not require further testing.

Routine Verification Checklist (Clause 11)

Routine Verification ensures that every manufactured assembly conforms to the verified design before dispatch.

This verification, performed by the Assembly Manufacturer, includes:

1. Visual inspection and wiring check (Clause 11.6)

2. Verification of terminals for external conductors (Clause 11.7)

3. Mechanical operation check (Clause 11.8)

4. Dielectric power-frequency test (Clause 11.9)

5. Continuity of protective circuits (Clause 11.3)

6. Functional testing, markings, and labeling verification

Resistance between each exposed conductive part and the PE terminal must not exceed 0.1 Ω when tested with 10 A (AC or DC).

The results, together with the design verification data, are retained in the Technical File for traceability and CE conformity.

CE Compliance Pathway: Documentation and Directives

For assemblies sold within the European Economic Area, CE marking confirms conformity with essential EU directives.

IEC 61439 compliance supports these directives through harmonized standards, particularly:

• LVD 2014/35/EU – Electrical safety for voltages between 50–1000 V AC and 75–1500 V DC.

• EMC 2014/30/EU – Control of electromagnetic emissions and immunity.

To demonstrate compliance, manufacturers must produce two key documents:

1. Declaration of Conformity (DoC): Signed by the responsible person, identifying applicable directives and standards.

2. Technical File: Comprehensive documentation including design verification reports, component certificates, electrical diagrams,

test reports, and risk assessments.

This file must be available for inspection by EU authorities for at least ten years after the last date of manufacture (Decision 768/2008/EC).

Marking and Nameplate Data (Clause 5.1)

The assembly nameplate provides traceability and operational information. IEC 61439-1:2021 mandates inclusion of the following data:

• Manufacturer’s name or trademark

• Type designation or serial number

• Date of manufacture or traceable code

• Applicable IEC 61439 part (e.g., -2 or -6)

• Rated voltage (Ue) and current (In)

• IP rating and, if declared, IK impact rating

• Short-circuit data (Icw, Ipk, Icc)

• Rated insulation (Ui) and impulse voltage (Uimp)

• Rated diversity factor (RDF), if relevant

Label durability is verified by rub tests with water and petroleum spirit for 15 seconds each; the information must remain legible afterward.

IEC 61439 vs UL 508A: Comparative Overview

When exporting panels to North America, it is essential to distinguish between IEC 61439 (global) and UL 508A (U.S. standard for industrial control panels).

IEC 61439 emphasizes performance-based design verification; UL 508A prescribes construction and component use rules.

| Aspect | IEC 61439 | UL 508A |

| — | — | — |

| Scope | Switchgear & Controlgear Assemblies | Industrial Control Panels |

| Verification | Testing, Comparison, Assessment | Prescriptive Construction Rules |

| Responsibility | Original vs. Assembly Manufacturer | Panel Shop or UL Listed Facility |

| Short-Circuit | Icw/Ipk/Icc (performance) | SCCR based on component data |

| Thermal | RDF concept, calculation methods | Fixed temperature limits, no RDF |

IEC 61439 compliance can often be used as supporting evidence for UL field evaluations, but direct UL certification still requires NRTL approval.

Conclusion: Ensuring Safety, Reliability, and Compliance

IEC 61439 represents the global benchmark for low-voltage assembly design and verification.

By combining flexibility in verification methods (testing, comparison, assessment) with strict accountability in documentation and testing,

it enables both safety and innovation. Panel builders adhering to its framework gain market credibility, simplified CE marking,

and improved long-term reliability.

From temperature-rise management and short-circuit withstand verification to creepage distances, dielectric tests,

and mechanical robustness, the standard demands a holistic engineering approach.

Each clause contributes to one overarching goal: ensuring that low-voltage assemblies remain safe, reliable, and compliant throughout their operational life.

source

Dielectric Properties & IP Rating

Routine dielectric test (power‑frequency, usually 1 s) checks insulation. Test voltage depends on Ui of the assembly. Any door/cut‑out modification must keep the declared IP—use proper gaskets and tested accessories.

Creepage & Clearance Basics

Use IEC 60664‑1 tables. Choose clearance per rated impulse withstand and installation altitude. Choose creepage per pollution degree (often PD2 in clean industrial panels) and CTI of insulating material. Remember higher altitude needs correction (bigger clearances).

Routine Verification Checklist (Factory Tests)

Before shipping the panel, do routine verification on every assembly:

- Visual inspection: markings, wiring, terminals for external conductors, protection against electric shock.

• Mechanical function: interlocks, doors, withdrawable parts work correctly.

• Wiring checks: continuity of protective circuits, torque of terminals, conductor sizes.

• Dielectric test: apply specified voltage for 1 s; record pass/fail and test set.

• Functional tests: operate devices and verify control circuits.

Use a standard test report template and keep it signed with serial/date.

For a fuller picture of electrical panel standards, explore our deep dives on IEC 61439-1/-2 (general rules for PSC), temperature-rise & RDF, short-circuit ratings & SCCR, creepage & clearance (IEC 60664-1), IP/IK enclosure ratings, EMC (immunity & emissions), forms of internal separation, UL 508A vs IEC 61439, and IEC 61439-6 busbar trunking.

EU CE Compliance Path (EN 61439 + LVD/EMC)

For Europe, use EN 61439‑1/-2 as harmonised base. Prepare Declaration of Conformity and a technical file referencing LVD 2014/35/EU for safety and EMC Directive 2014/30/EU with EN 61000‑6‑2 (Immunity) and EN 61000‑6‑4 (Emissions) . Keep design verification evidence, routine test report, wiring diagram, nameplate sample, and risk assessment in the file.

IEC 61439 vs UL 508A

IEC/EN 61439 is EU framework for assemblies ; UL 508A is a North American standard for industrial control panels. They have different terminology and test philosophy. If you export to USA, follow UL 508A and sometimes UL 891 for switchboards. For EU projects, keep EN 61439 focus; for dual market panels, plan two compliance paths from day one.

FAQ