When it comes to industry there are two standards to determine the different grades of electrical enclosure against infiltration of external substances.

IP and NEMA both evaluate electrical units’ resistance points against water and dust while using different verification approaches to define their enclosure type.

For your convenience, if you prefer listening, you can listen to the rest of this article via the audio file below.

What IP55 and NEMA 12 Mean?

The “NEMA” acronym stands for the National Electrical Manufacturers Association, which is the upholder for the industry and publishes standards for electrical products.

On the other hand, IEC stands for International Electrotechnical Commission. They are an international organization that establishes the basis of the design, manufacturing, testing, and certification parameters of electrical components.

In order to narrow down this broad topic we should note that NEMA and IEC are classification systems for electrical enclosures.

Ingress Protection Code Basics

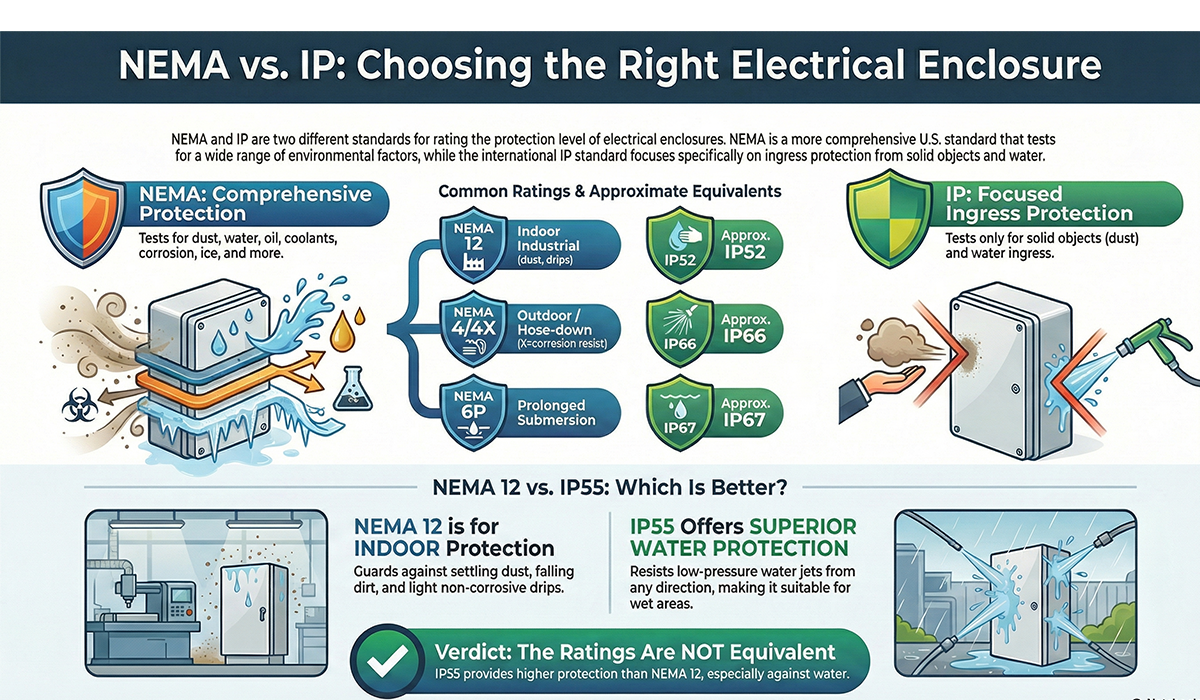

ICE 60529 ratings have been developed through only three types of tests; protection of people from hazardous internals, prevention of solid objects from entering, water ingress prevention (only water, it doesn’t cover coolant or other corrosives). The ratings for this certification usually are stated with an IP code which stands for “International Protection”.

The IP code is written as IP followed by two numbers; the first digit determines the protection against solid materials, and the second digit determines the protection against water.

For instance, IP55 rates a unit that is dust-protected and can resist water jets.

NEMA Type Rating Scope

NEMA 250 categories classify enclosures based many experiments; the capability of preventing human access, solid materials ingress prevention, liquids ingress prevention, construction concern, door and cover securement, corrosion resistance, ice impact, gasket ageing and oil resistance and cooling effectiveness.

| NEMA Rating | Approximate IP Equivalent | Best Use Case |

| NEMA 1 | IP10 | Indoor, basic protection from touch. |

| NEMA 2 | IP11 | Indoor, protects from dripping water/dirt. |

| NEMA 3 / 3S | IP54 | Outdoor, rain and windblown dust. |

| NEMA 3R | IP14 | Outdoor, rain/sleet (often ventilated). |

| NEMA 4 / 4X | IP66 | Hose-down, splashing water, and dust. |

| NEMA 6 / 6P | IP67 | Occasional/prolonged submersion. |

| NEMA 12 | IP52 | Indoor, protection from dust and non-corrosive drips. |

| NEMA 13 | IP54 | Indoor, protects against oil and coolant seepage. |

This rating safeguards against the ingress of objects, fingers, falling dirt, settling dust, and drips. It is similar to NEMA 3 but it has been designed for indoor use. Instead of protecting against windblown dust, it adds protection against settling airborne dust, lint, and fibers. Nevertheless, it does not protect against rain, sleet, or snow, it offers protection against oil and coolant seepage, as well as light splashes and drips of water. Despite its higher number, it provides a basic level of protection, and it may be more accurate to consider it a step up from NEMA 1 rather than a full NEMA 12 rating.

Are IP55 and NEMA 12 Equivalent?

NEMA 250 and ICE 60529 standards do not overlap due to their different approaches of testing, however since NEMA covers more testing parameters, the ratings can meet or exceed the IEC 60529 ratings. Thus, we can use NEMA as the place of an IP rating but it can not be true other way around as IP does not determine protection against oils, coolants, corrosive agents, or ice.

The following chart helps you determine the closest correspondent for each NEMA and IP ratings.

The answer to the question on whether NEMA 12 is equivalent to IP55, would be NO. You can read more about NEMA 12 is equivalent to IP55.

When IP55 Outperforms NEMA 12

NEMA 12 is a certification for basic indoor use cases providing protection only against falling dirt, settling dust, and light splash water.

Whereas IP55 offers substantially higher protection, particularly against low-pressure water jets from any direction.

As a result if you put NEMA 12 and IP55 in comparison, IP55 would offer higher protection.

Test Methods and Criteria

NEMA certification determines enclosure performance through standardized testing for specific ratings (e.g., NEMA 4X). Include ingress protection (dust/water), impact resistance, environmental endurance (temperature/corrosion), and mechanical stress (vibration/shock). These tests ensure equipment remains functional and protected against physical damage and dangerous external conditions.

On the other side the IP (Ingress Protection) system also measures how well enclosures resist external elements:

Solids (IP 0X–6X): Tests range from large object interference to fine dust exposure. IP6X is the highest rating, ensuring a completely dust-tight seal.

Liquids (IP X0–X8): Tests scale from water jets to high-pressure immersion. IPX7 covers temporary submersion (1m for 30 min), while IPX8 ensures protection during continuous submersion at greater depths.

Water Protection Differences

To understand why NEMA and IP ratings are not interchangeable; it is essential to look at the exact physical parameters used during the water protection tests. While both systems aim to ensure a “watertight” seal, they use different tools (nozzles), pressures, and durations.

Dust and Oil Protection

When it comes to comparing dust and oil protection, the biggest difference is that the NEMA standard has a dedicated rating for oil (NEMA 13), whereas the international IP standard (IEC 60529) focuses only on solids (dust) and water.

Indoor vs Outdoor Suitability

Choosing an enclosure based on whether it will be used indoors or outdoors is crucial. A high-protection indoor enclosure (like NEMA 12) will often fail quickly outdoors because its design purpose would not handle UV rays, freezing ice, or heavy rain.

Corrosion-Resistance Considerations

To deal with corrosion, the primary thing to consider is the “X” factor. In the NEMA system, the letter “X” (as in NEMA 4X or 3RX) determines that the enclosure has passed specific, rigorous corrosion testing that standard IP-rated or non-X NEMA enclosures are not required to provide.

NEMA 12 vs NEMA 4

The comparison between NEMA 12 and NEMA 4 is basically a choice between “Indoor Industrial” and “Outdoor” use cases. While both are “dust-tight” they differ primarily in how they handle water and environmental stress. You should also bear in mind that despite NEMA 4 and NEMA 4X offering identical protection against water and dust, the “X” is the important factor that validates verified resistance to corrosion.

Selection Guide for Electrical Enclosures

To choose the best enclosure that meets your needs you should first understand your desired environment’s condition, then choose wisely.

For indoor use, NEMA 12 provides a reliable seal against infiltration of dust and falling liquids, roughly equivalent to IP54. If the environment is clean and dry, NEMA 1 or IP10 suffices for basic safety. In industrial settings involving oil or coolants, NEMA 13 is the superior choice because IP ratings do not specifically test for oil resistance.

Gasket and Seal Materials

When selecting an electrical enclosure, thermal management trade-offs between conduit and gland sealing must be considered. Conduit sealing offers superior protection from dust, moisture, and environmental hazards, but it can limit airflow, potentially leading to higher temperatures and reduced heat dissipation. Gland sealing, on the other hand, allows better airflow, supporting thermal performance, but provides less protection against external elements. It’s easier and more cost-effective to install and maintain. The choice between conduit and gland sealing depends on balancing the need for environmental protection with the requirement for efficient heat dissipation, with each option having distinct advantages based on application needs.

You can read this article if you want to learn more

Applications and Examples

NEMA 12 enclosures are commonly used in industrial settings for protecting electrical equipment from dust, dirt, and non-corrosive liquids. These enclosures are ideal for indoor applications like control panels, motor drives, and sensors. However, their limitations include reduced protection against water and extreme environments. IP55 enclosures, with their dust-tight and water-resistant properties, are suitable for industrial applications exposed to water jets and harsh conditions, providing superior protection in outdoor or wet environments.

Standards and Acceptance (US/EU)

UL 50 and UL 50E are standards for the design and manufacturing of electrical enclosures in the United States, ensuring safety against environmental factors like dust, moisture, and impact. UL 50 covers general enclosures, while UL 50E addresses enclosures used in outdoor and harsh environments. CSA C22.2 No. 94.2 aligns with Canadian safety standards for enclosures, similar to UL standards. IEC 60529, an international standard, defines the ingress protection (IP) ratings for enclosures, specifying the level of dust and water protection. These standards ensure safety, performance, and compliance across different regions.

Conclusion

IP55 and NEMA 12 may sound like they live in the same neighborhood, but they play by very different rules. NEMA 12 is an indoor-focused standard built for controlled industrial environments with dust, falling debris, and light splashes, while IP55 is designed to handle harsher exposure, especially water jets from any direction. Because NEMA and IP use different test methods and priorities, they are not interchangeable, and assuming equivalence is a fast way to choose the wrong enclosure. The correct selection always comes down to environment, exposure, and regulatory requirements. Ignore the numbers alone, understand the conditions, and the enclosure will quietly do its job instead of becoming the weakest link in your system.