Understanding pollution degree and overvoltage category is essential for ensuring the proper insulation and safety of electrical systems. These classifications define the environmental conditions and transient voltage exposure that affect device performance and longevity. By accurately selecting the right pollution degree and overvoltage category, engineers can optimize insulation coordination and enhance system reliability. This guide explores the key factors involved in choosing these parameters and their impact on electrical installations and busbar fabrication machines.

Prefer listening? You can play the audio version of the rest of this article below.

Pollution Degree and Overvoltage Category: Classifications

Pollution Degree and Its Classification According to IEC 60664-1 and IEC 61010-1

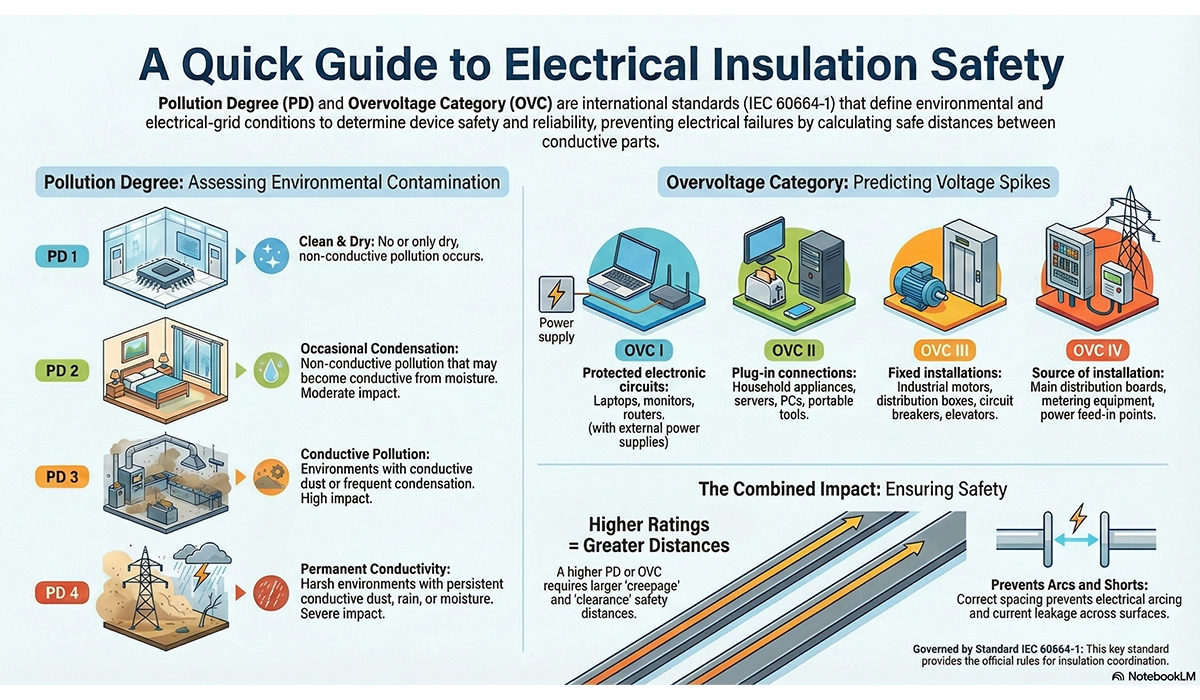

The pollution degree describes the type and intensity of pollution that can affect the insulation of electrical components. It is divided into four degrees, each requiring different levels of insulation and protection for devices:

Pollution Degree 1: This degree refers to areas where no or only minor, non-conductive pollution occurs. In such environments, pollution does not affect the function of the components. Devices used in these areas only require standard insulation, which can be achieved through special coatings.

Pollution Degree 2: Pollution can occur here that is non-conductive but may become conductive due to occasional condensation (dew) or, for example, hand sweat. Components used in these areas must be protected against these temporary pollutants to ensure safe operation.

Pollution Degree 3: This category defines pollution that is either already conductive (e.g., metal dust) or may become conductive due to dew. Components installed in such environments must be shielded accordingly and have higher robustness against conductive pollution.

Pollution Degree 4: The highest pollution degree describes environments where permanently conductive pollution, such as dust, rain, or moisture, is expected. These environments pose the greatest challenge to insulation, and components in these areas must be designed to be particularly robust to meet the requirements.

Pollution degree and overvoltage category are crucial for insulation coordination in electrical systems. These parameters influence the sizing of the creepage distance and the distance between conductive parts. To ensure precise insulation selection and account for environmental conditions, it is important to choose the right classifications. For more information on how these classifications affect the selection and application of busbar fabrication machines, see our guide to busbar fabrication machines.

Overvoltage Categories

Definition of Overvoltage Category (Installation Category)

The overvoltage category (also called the installation category or overvoltage category, OVC) defines the expected level of transient overvoltages that an electrical device will be exposed to, depending on its position in the power supply system. It is a key criterion for insulation coordination and particularly influences the design of the required air and creepage distances.

Overvoltage Category | Rough Rule for Device Assignment | Rated Impulse Voltage | Typical Devices and Machines in This Overvoltage Category |

|---|---|---|---|

| I | Devices using an external transformer/plug-in power supply | 1,500 Volts | Examples include: laptops, monitors, telephones, switches, external hard drives, POS terminals, LAN-WLAN routers, repeaters, video door systems, surveillance cameras |

| II | Devices with a cold appliance connector | 2,500 Volts | Examples include: household appliances, portable tools, PCs, printers, copiers, telephone systems, NAS, servers, laboratory equipment, heating control, temperature regulators, cash registers, bread machines, toasters, microwaves, kitchen appliances, satellite receivers |

| III | Devices that are directly connected (no plug) | 4,000 Volts | Equipment in fixed installations or cases where special requirements for reliability and availability of the equipment are demanded, such as: switches in fixed installations (RCDs), industrial equipment permanently connected to fixed installations (stationary motors, CNC machines), fuse circuit breakers, outlets, distribution boxes, switches, modular devices, UPS systems, energy sources, elevators, lathes, CNC milling machines, drills, stamping machines, lifts, gate drives, cooktops, ovens |

In the VDE standard DIN EN 60664-1 VDE 0110-1, four overvoltage categories: I, II, III, and IV are defined. The classification is not based on a fixed “overvoltage degree” but rather on the device’s integration into the power grid and the resulting exposure to transient overvoltages, such as switching actions or indirect lightning effects.

The IEC 60664-1 (DIN EN 60664-1 VDE 0110-1) standard defines four overvoltage categories (I–IV). The following table extends this classification with an additional category by the manufacturer, which is not part of the standard.

The table provided here gives information about overvoltage categories 1–4 in the VDE standard DIN EN 60664-1 VDE 0110-1.

Overvoltage Category I (OVC I)

This category applies to equipment that is connected to circuits where measures have been taken to limit transient overvoltages (e.g., internal protection circuits).

Typical rated impulse voltages range from about 1.5 kV.

Typical devices: Electronics with external power supply, sensitive signal and measuring devices.

Overvoltage Category II (OVC II)

This category includes equipment connected to fixed installations via sockets. Typical rated impulse voltages in low-voltage networks are usually around 2.5 kV.

Typical devices: Household appliances, office equipment, servers, IT equipment.

Overvoltage Category III (OVC III)

OVC III applies to equipment that is part of fixed electrical installations and closer to the energy distribution. Typical rated impulse voltages range from about 4 kV depending on the nominal voltage.

Typical devices: Switchgear, distribution systems, stationary motors, industrial control systems.

Overvoltage Category IV (OVC IV)

This category applies to equipment at the origin of the electrical installation, where the highest transient overvoltages can occur. Typical rated impulse voltages can reach about 6 kV in low-voltage networks.

Typical devices: Feed-in points, main distribution boards, metering equipment, equipment in substations.

Overvoltage category is always considered in conjunction with the pollution degree, rated voltage, type of insulation, and material group to ensure proper and safe insulation coordination.

How Pollution Degree and Overvoltage Category: Affect Creepage Distance and Clearance

Pollution degree and overvoltage category provide the means to increase the required minimum values for creepage and air distances: A higher pollution degree (e.g., from degree 2 to degree 3) leads to stronger pollution that becomes conductive and creates shorter paths for creepage currents, requiring larger distances. A higher overvoltage category means the device must withstand higher transient voltages, which also requires larger distances to avoid arcing (air distance) and creepage paths (creepage distance).

The dimensioning of creepage and air distances depends directly on the overvoltage category (which defines the expected transient overvoltages) and the pollution degree (which describes the extent of environmental pollution). The higher these values, the larger the distances between conductive parts must be to prevent electrical breakdown and surface creeping.

Understanding insulation coordination requires not only knowledge of pollution degree and overvoltage categories but also how these principles apply in real-world electrical infrastructure. For insights into how these standards influence practical designs, see Busbar Systems Inside Power Switchboards to connect theoretical criteria with actual busbar implementation. This helps bridge theory and application for safer, more reliable installations.

Connection to Insulation Coordination and IEC 60664-1

This section of IEC 60664 contains provisions for insulation coordination for devices connected to low-voltage systems with a rated AC voltage up to 1,000 V or a rated DC voltage up to 1,500 V. This document applies to frequencies up to 30 kHz. Requirements for insulation coordination for electrical devices in low-voltage systems with rated frequencies over 30 kHz are included in IEC 60664-4.

Creepage distance and clearance are crucial for the safety and insulation of devices. They depend on:

- Operating and rated voltage,

- Type of insulation and material group,

- Pollution degree of the environment,

- Overvoltage category, and

- Other factors such as temperature, humidity, and device construction.

All these factors must be carefully considered to ensure proper insulation and the appropriate distances in electrical installations.

Pollution Degree and Overvoltage Category Applied in Practice for Low-Voltage/Mid-Voltage Switchgear and Busbar Systems

Typical Assumptions for Low-Voltage Switchgear

In practice, for standard devices in low-voltage switchgear, pollution degree 2 (PD2) and overvoltage category II (OVC II) are often assumed, as these devices are typically exposed to minimal, non-conductive pollution in environments such as offices or homes. However, for distribution systems in buildings, overvoltage category III (OVC III) is often used because these systems are exposed to higher transient overvoltages and permanently installed components.

Non-Official Design Cheat-Sheet: Selecting Pollution Degree and Overvoltage Category

Step 1: Analyze Environmental Conditions

Determine the pollution degree (PD): Consider where the device will be installed (e.g., office, industrial hall, outdoors). Then, consider moisture, dust, or corrosive substances. Choose the pollution degree (PD1 to PD4) based on these factors:

- PD1: Clean, dry environments.

- PD2: Occasional moisture or minor pollution.

- PD3: Industrial environments with conductive dust.

- PD4: High pollution, e.g., moist environments or outdoor use.

Step 2: Determine the Overvoltage Category (OVC)

Analyze the device’s position in the power grid:

- Devices directly connected to the power source require a higher overvoltage category.

- OVC I: For devices plugged into outlets.

- OVC II: For devices in areas like homes or offices.

- OVC III: For fixed devices in distribution systems or industrial settings.

- OVC IV: For devices at the power grid entry point.

Step 3: Consider Insulation Criteria

Check which insulation is used:

- Plastic, ceramic, glass or other insulating materials affect how much voltage and pollution the device can withstand.

- Then, based on the insulation, choose the appropriate creepage distance and clearance, as defined in standards like IEC 60664-1.

Step 4: Check Standards and Codes

- Standards such as IEC 61439, IEC 60664-1, and VDE 0110-1 provide specific requirements on how pollution degree and overvoltage category should be set for different devices and installations. Ensure all selection criteria match current standards.

Step 5: Practical Implementation

- Calculate the required creepage distance and clearance based on the established parameters.

- Consider safety and longevity: If unsure, select a higher category (e.g., OVC III instead of OVC II) to be on the safe side and absorb higher transient overvoltages.

Conclusion

Insulation coordination in low-voltage and medium-voltage systems is critical for the safety and efficiency of electrical installations. Pollution degree and overvoltage category play an essential role, as they significantly impact the requirements for insulation and the distance between conductive parts. The pollution degree and overvoltage category refer to environmental influences such as dust, moisture, and corrosive substances, which determine how robust the insulation must be to prevent creepage currents and insulation failures. Equally important is the overvoltage category, which describes the intensity of transient overvoltages and sets the distance between components to prevent arcing.

Precise selection of the correct pollution degree and overvoltage category is essential to ensuring the long-term operational safety and reliability of installations. By applying IEC standards and carefully planning insulation, creepage, and air distances, engineers and technicians can minimize potential risks and ensure high protection performance. In practice, companies should always consider the specific requirements of their respective environments and devices to ensure optimal insulation coordination and maximize electrical infrastructure safety.