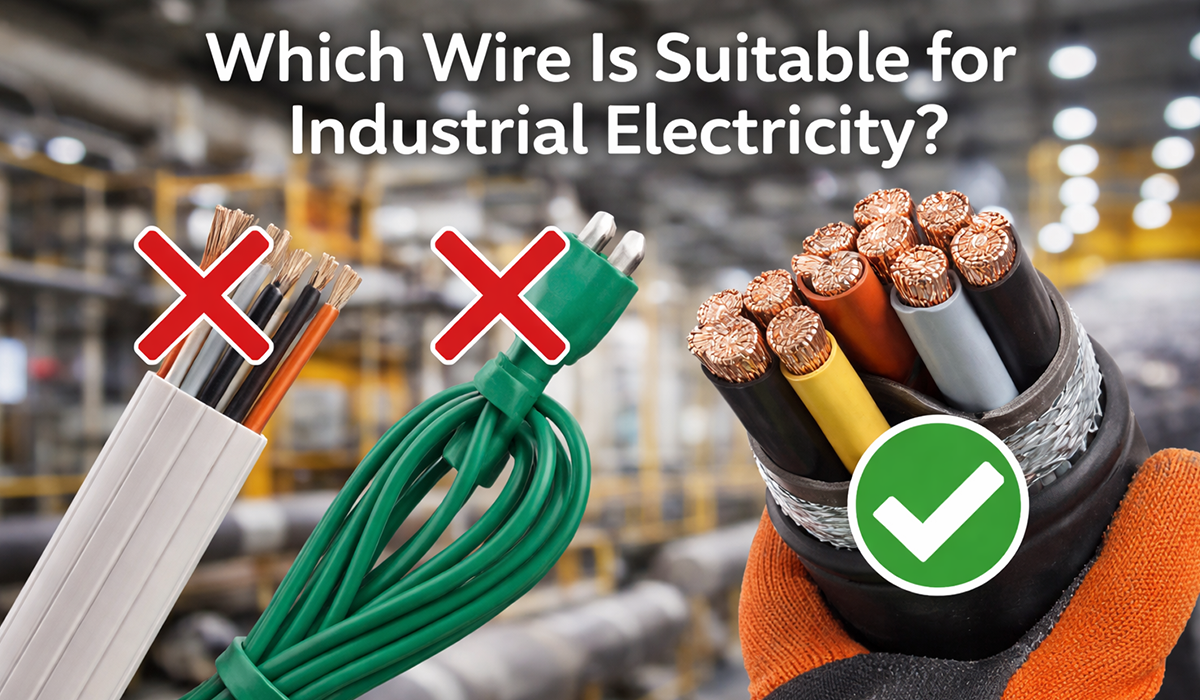

Choosing the right wire for industrial electrical systems is one of the most important decisions you need to make in installation and industrial projects, and it must be done with high accuracy. At first glance, you might think this is easy and that most wires can do the job, but you should know you’re making a big mistake.

The key point you must consider is that industrial environments have special and different conditions compared to residential use. Higher power demand, heavier currents, moisture, ambient heat, and even the type of equipment all make proper wire selection critically important. In the rest of this article, stay with us as we review the most important factors in selecting the right wire for industrial electricity, and help you understand the differences between industrial and residential electrical wiring.

Which wires are suitable for industrial electricity?

Industrial wires and cables are selected based on conductor material, insulation type, and voltage level, and each one has a specific application in industrial environments. In general, the following are suitable options for industrial electricity:

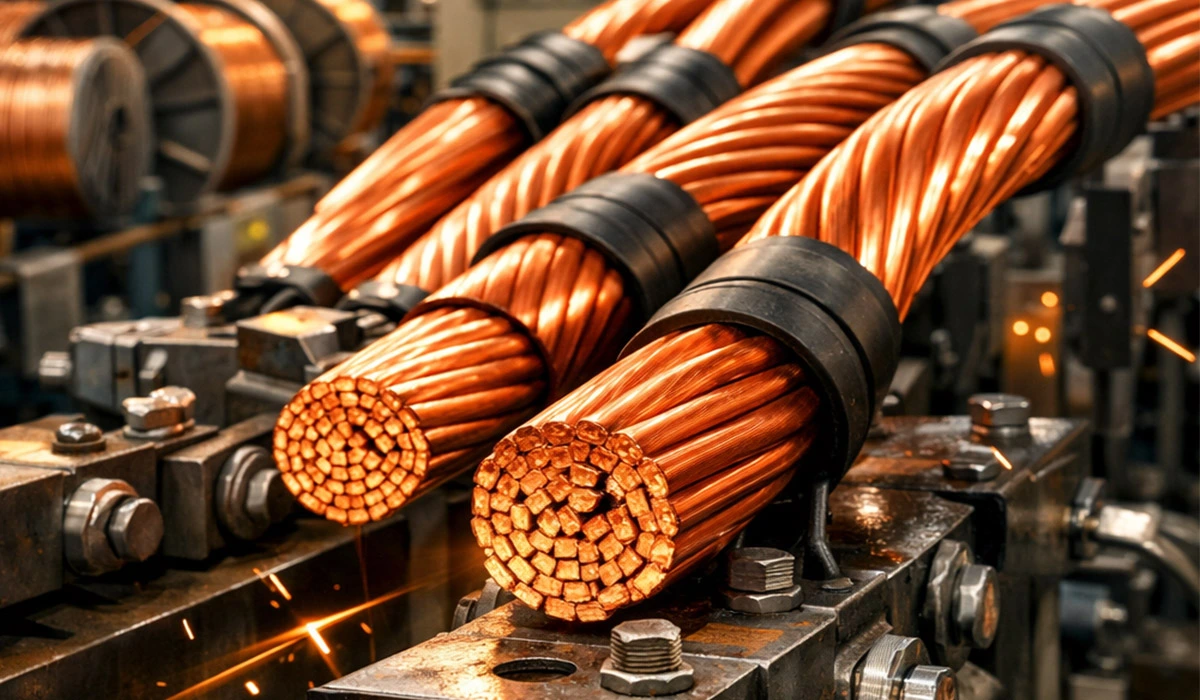

- Copper wire: Due to high electrical conductivity, strength, and longer service life, it is considered the best option for industrial electricity.

- Aluminum wire: Compared to copper, it is lighter and cheaper, and is a suitable option for projects with limited budgets.

- PVC-insulated wire: Common and economical, and a suitable option for general environments with moderate conditions.

- XLPE-insulated wire: Highly resistant to heat and chemicals, which makes it ideal for high voltages and harsh environments.

- EPR-insulated wire: Has high flexibility and resistance against moisture, so it is used in humid or marine environments.

- Shielded wire (foil or braided): Its ability to prevent noise and electromagnetic interference makes it an excellent option for control and instrumentation cables.

- LSZH-sheathed wire: Due to high fire safety and minimal smoke and toxic gas production, this wire is a suitable choice for sensitive environments such as tunnels and buildings.

- Low Voltage (LV) cable: Used for light applications and internal power distribution.

- Medium Voltage (MV) cable: Used in industries and urban distribution networks.

- High Voltage (HV) cable: Specifically for large-scale power transmission between power plants and the main grid.

If this content has been valuable to you, we recommend reading the related article on topic Electrical wiring for further insights.

Key factors in selecting industrial electrical wire

Selecting wire for industrial electricity has its own process. That means when choosing the wire you need, you should first pay attention to several different factors. These important factors include:

- Required current and voltage: The wire must carry the equipment’s power and current without overheating or voltage drop.

- Environmental conditions: Various environmental factors such as temperature, humidity, chemicals, or mechanical hazards determine the type of insulation and sheath.

- Standards and regulations: The wire must comply with recognized standards (IEC, UL, ANSI) to ensure safety and quality.

- Application type: Depending on the purpose (power transmission or control signals), the cable type will be different.

For more information on this topic, it is recommended that you also read article Factors to Consider When Selecting Industrial Cables.

Choosing between stranded and solid wire depends on your working conditions and project requirements. Solid wire (also known as rigid wire) has high mechanical strength, so it is a reliable option for electrical panels and fixed routes. On the other hand, stranded wire, because of its high flexibility, is used more in moving wiring or where bending and easy installation are needed. Simply put, if your work environment is fixed and without movement, solid wire is the better choice, but if you’re dealing with complex routes, vibration, or moving equipment, stranded wire is the best option.

If this content has been beneficial, we recommend reading the article on topic solid wire for industrial for more details and precision.

The difference between industrial and residential electrical wire

When choosing suitable wire for industrial electricity, you should also know how it differs from residential wiring. Industrial and residential wires differ fundamentally in current capacity, strength, and design. Industrial wire is made for harsh conditions and heavy loads, while residential wire is used for everyday and light applications. In the table below, you can see all the key differences between industrial and residential wire.

If this article has been helpful, we encourage you to read the article on topic The differences between industrial electrical installations for a deeper understanding of the subject.

| Feature | Voltage and current | Structure |

| Industrial electrical wire | High voltage and current capacity, often three-phase | Thicker insulation and sheath, resistant to heat, moisture, and chemicals |

| Residential electrical wire | Lower voltage, single-phase | Simpler insulation, suitable for indoor environments |

| Feature | Strength | Application |

| Industrial electrical wire | Resistant to abrasion, impact, and harsh conditions | Factories, workshops, heavy machinery, production lines |

| Residential electrical wire | More flexible and lighter | Household electrical appliances, lighting, and outlets |

| Feature | Connections |

| Industrial electrical wire | Locking industrial connectors |

| Residential electrical wire | Standard plugs and outlets |

conclusion

In conclusion, choosing the right wire for industrial electrical systems is crucial for ensuring safety, efficiency, and longevity. By considering factors such as required current, voltage, environmental conditions, and the specific application, you can make an informed decision that meets industry standards and regulatory requirements. The distinction between industrial and residential wiring is significant, with industrial wires designed for more demanding conditions, such as high voltages, moisture, and chemicals, while residential wires cater to lighter, everyday use.

Whether opting for copper, aluminum, or specialized insulated wires, selecting the appropriate type based on the specific demands of your project can make all the difference. Always ensure that your choice complies with relevant standards such as IEC, UL, or ANSI to guarantee both safety and reliability. Keep in mind that the success of your electrical system depends heavily on the quality of the wiring, and investing in the right materials from the start will prevent costly repairs or failures down the line.

By understanding the complexities of industrial electrical wiring, you not only secure optimal performance but also enhance the durability and safety of your electrical infrastructure.

Frequently Asked Questions

1) What is the best wire for industrial electricity?

Copper wire with XLPE insulation or durable PVC insulation is a suitable choice for most industrial projects.

2) Can we use residential wire in industry?

No. Residential wire does not have the required capacity and safety for heavy loads and industrial conditions.

3) Is stranded wire better or solid wire?

Stranded wire is more suitable for moving routes and easy installation, but for fixed routes and electrical panels, solid wire is the better option.

4) What factors matter most when selecting suitable industrial electrical wire?

Factors such as equipment power demand, environmental conditions, standards, and application type are highly important.

5) Is aluminum wire also used in industry?

Yes. In projects where weight or cost is very important, you can use it, but you should know its durability and performance are lower compared to copper wire.