In the fast-paced world of electrical manufacturing, efficiency and versatility are key to staying competitive. The traditional approach involved using separate machines for cutting, punching, and BENDING BUSBAR, which often led to increased space requirements, higher costs, and longer production times. Today, innovative solutions like PAYAPRESS’s multi-functional BUSBAR MACHINE are transforming the industry by offering integrated capabilities that bring numerous advantages.

The Concept of a 3-in-1 Busbar Machine

A 3-in-1 BUSBAR MACHINE combines three essential processes—cutting, punching, and bending—into one compact, efficient unit. This integration allows manufacturers to perform multiple operations without transferring workpieces between different machines, streamlining the entire fabrication process.

Key Benefits of Multi-Function Busbar Machines

- Space Savings

Traditional setups require multiple dedicated machines, consuming valuable workshop space. A single multi-functional machine consolidates these operations, freeing up space for other equipment or workspace environment improvements.

- Cost Efficiency

Investing in one versatile machine reduces capital expenditure compared to purchasing separate units. Additionally, it lowers overhead costs related to maintenance, energy consumption, and machine operation.

- Enhanced Productivity

With multiple processes occurring within one machine, production cycles are shortened. Operators can switch between functions seamlessly, significantly increasing throughput and minimizing downtime.

- Improved Accuracy and Consistency

Performing all operations on one machine reduces errors caused by moving workpieces between different tools. The likelihood of misalignment during transfer is eliminated, leading to higher precision in dimensions and better overall quality.

- Simplified Workflow and Reduced Handling

Having an integrated machine simplifies workflow, making it easier for operators to manage tasks, optimize sequences, and maintain quality control. Reduced handling also decreases the risk of damage or contamination.

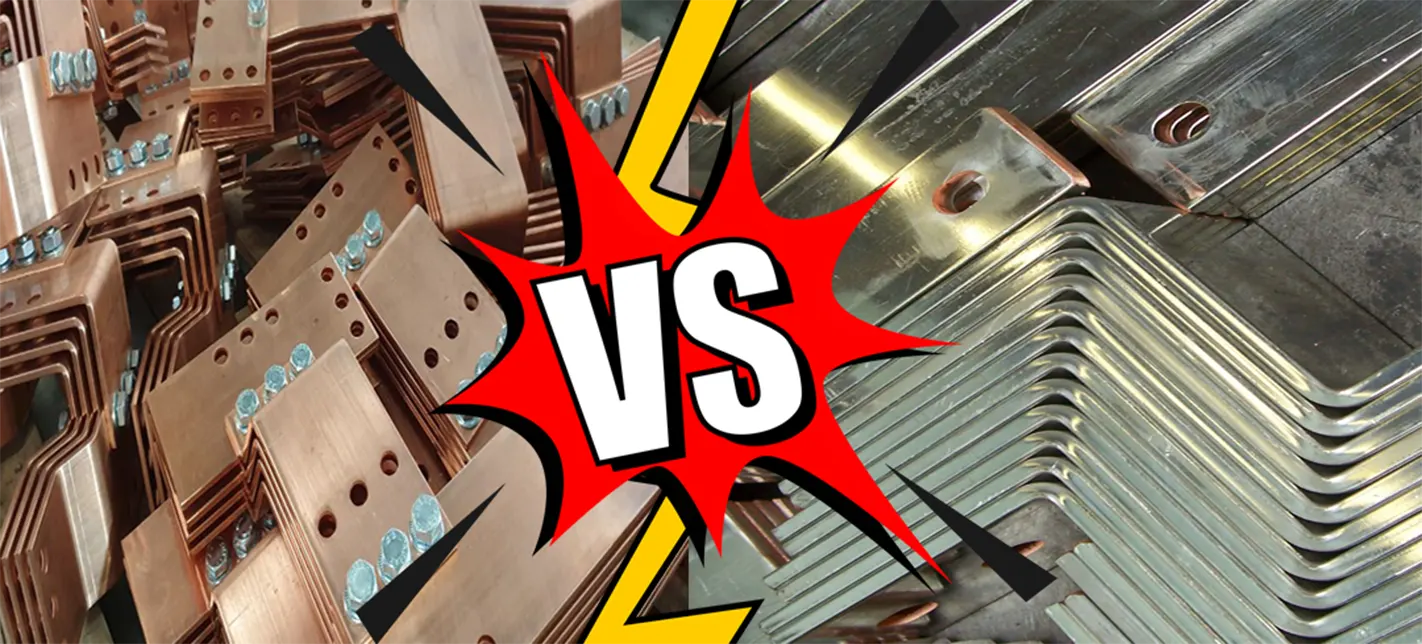

- Flexibility in Manufacturing

Multi-functional busbar machines accommodate various sizes and types of busbars, providing manufacturers with the flexibility to adapt to different job requirements quickly and efficiently.

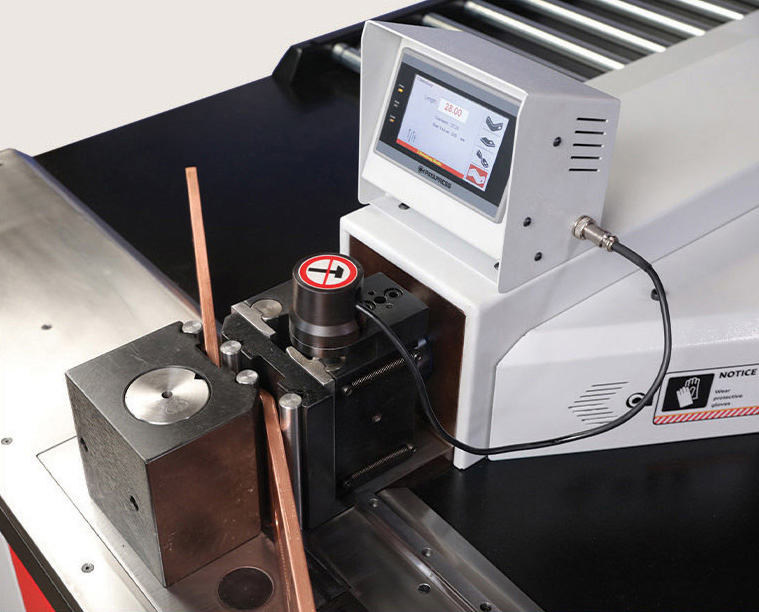

- User-Friendliness

Modern integrated machines, like those from PAYAPRESS, feature intuitive interfaces, programmable settings, and digital controls, making them accessible even for operators with limited experience.

Why Choose PAYAPRESS Multi-Functional Machines?

PAYAPRESS’s 3-in-1 busbar machines are equipped with advanced features such as:

- Programmable length stop for precise PUNCHING

- Digital bending indicators for accurate bends

- Industry 4.0 connectivity for real-time feedback and troubleshooting

These features help ensure that your production process is efficient, accurate, and adaptable to future demands.

Conclusion

Integrating multiple BUSBAR PROCCESING functions into a single machine offers substantial advantages—saving space, reducing costs, increasing productivity, and ensuring consistent quality. For manufacturers looking to optimize their operations, invest in PAYAPRESS’s multi-functional busbar machines to stay ahead in a competitive market. Embracing this technology will not only streamline your workflow but also elevate the quality of your products.