Competitive Advantage of Payapress for order busbar machine

Advantages of the new HBC-A BusBar table over the old ones >

Payapress could take advantage of getting feedbacks from customer after-sales service to enhance the technical information of its machinery.

Now, after more than twenty years of our first machines production, many improvements have been made in the Busbar table machines, which we will explain the advantages of the current production machine compared to the old machines as below:

Generally, PayPress now has the possibility of making Busbar tables with the ability to bend copper bar up to 170, which are usually produced in two models, HBC-A120 and HBC-A160.

3 in 1 busbar machine

Competitive Advantage of Payapress for order busbar machine

1-Bending

-Installation of the 3600-pulse direct coupling encoder on a moving roller

– Perform bending operations in two stages. In fact, all sheet metals in the bending process have a certain amount of reversibility.

-Possibility of installing various bending molds such as bending on the edge of the busbar (male bending) and bending with short distance (Z bending) and torsional bending (Twist bending)

– Complete design of bending system by Payapress company

– Use full touch screen with highly efficient and error-free programming

See our products — > Busbar Machine

2 – Cutting

The center finder of the cutter, which causes the vertical cutting of the ingot

Ability to install digital ruler (system metering) to increase the accuracy and precision of the cutting process

Use double-sided blade to increase the lifespan of Busbar Fabrication machine

Place rollers on the table to facilitate the movement of the busbar

Installation of manual adjustment in the Y axis of the busbar machine.

See our products — > Busbar Machine

Competitive Advantage of Payapress for order busbar machine

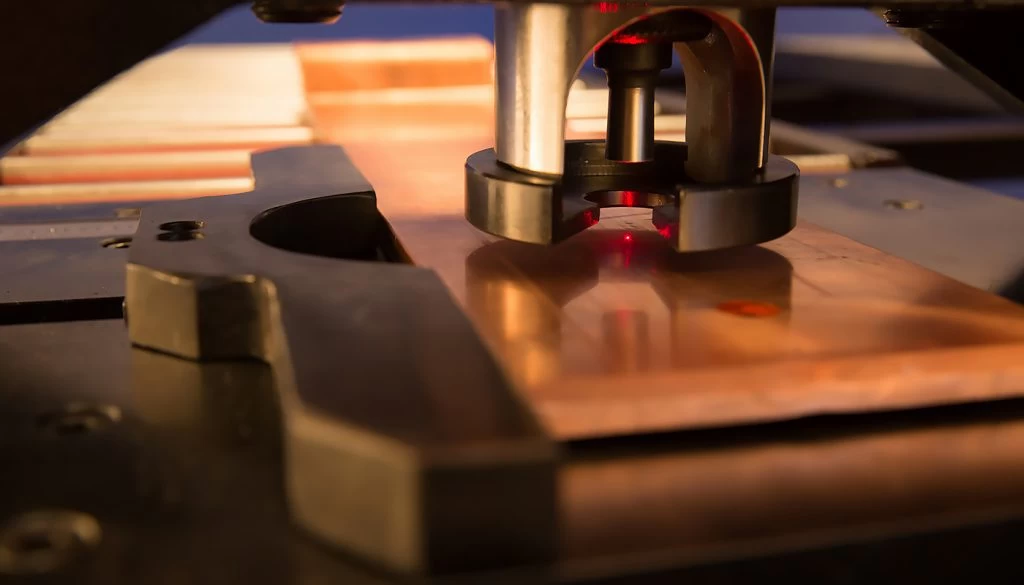

3 – Punching

Installation of the longitudinal and transverse position adjustment of the puncher, which is installed on the machine by Liner, and due to the lack of slack, the accuracy and speed of operation are high in performing the repetitive work process.

Quick replacement of dies: By changing the mechanism of the molds, the process of changing the molds is done very quickly and without wasting time.

Place roller on the table to facilitate Busbar movement

Installation of manual adjustment on the Y axis of the busbar machine.

order busbar machine

The appearance of Busbar Fabrication Machine

As it is comparable in the movie, the appearance of the busbar machine is not comparable to the old machines, and beautiful final cover of the machine gave a very good effect to the busbar fabrication machine as a widely used device in the electricity industry.