What is High-Voltage electrical panel and what is it made from?

The generators with more than 1000v are called High-Voltage, which need high-voltage electrical panels to feed them. It is so important to use electrical panels in industries! Because not only it helps the generator but also helps with its longevity.

One the main elements to the high-voltage electrical panel is the circuit breaker, they need specific features in order to function properly.

Therefore, there are many components in high-voltage electrical such as:

Oil, air and SF6 gas, each of them must follow required standards and quality to prevent any accident from happening.

high-voltage electrical panel’s main components are:

- 1- Cables: They are EPR or XLPE.

- 2- Insolation switch: the reason behind using these switches is to be able to maintain and fix them. Also, they must be able to withstand a short circuit for about a second.

- 3- Internal busbars: they are typically copper or aluminium and, in each phase, they can connect many wires and cables.

- 4- Kill switch: this switch can be manual or automatic. Bare in mind this switch dose not have any level of protection and typically can do maximum of 600 cut within an hour.

- 5- Brakers: Only parts of them which are used for: cut, control and protect simultaneously. You can also use them for features like: detecting ground leaking, or remote control and etc. you can extend their capability by adding cards or special module.

- 6- Contactors: These are simple devices installed in electrical panels for frequent switching (opening and closing) of circuits, and they typically operate via ON/OFF control signals. They include auxiliary contacts, both normally closed (N.C.) and normally open (N.O.), and are used in applications such as motor starting and switching capacitor banks.

- 7- Fuses: Generally, for high-voltage applications that require a high level of protection, a combination of HRC (High Rupturing Capacity) fuses and overload switches is used.

- 8- Suitable measuring equipment: In electrical switchboards/panels, certain parameters must be measured, such as phase and line voltage, line current in each phase, total power, and power factor.

- 9- Transient high-current protection equipment: Modern high-voltage switchboards are equipped with features such as surge overvoltage protection, which can protect high-voltage system components against the effects of transient overvoltages.

Important note: High-Voltage Switchgear Explosion

In most cases, the cause of an explosion in a high-voltage electrical switchboard/switchgear is the presence of an electrical arc and the heat generated by it. If an explosion occurs, it can cause serious damage to personnel, nearby equipment, the internal components of the panel, and the switchgear enclosure itself, such as motor-room switchboards, emergency switchboards, and other types of electrical panels. These damages are often irreversible.

Therefore, to prevent this kind of explosion, you should be familiar with topics such as hazard estimation, understanding regulations, performance assessment, and rapid response procedures.

For high-power applications, the 200 amp panel ensures stable power distribution and can handle a large number of electrical devices.

Factors affecting the price of high-voltage switchgear

- 1. Type of circuit breaker used

- 2. Safety level

- 3. Technology used in manufacturing

- 4. Features and functionality

Circuit breaker technologies used in switchgear

- SF₆ gas circuit breaker

- Air-blast circuit breaker

- Oil circuit breaker

- Vacuum circuit breaker

In any case, some high-voltage switchgear components can be expensive.

Also, due to market price fluctuations, pricing is not fixed. Therefore, before purchasing high-voltage switchgear parts and equipment, contact suppliers to get the latest prices.

Components of high-voltage switchgear

High-voltage switchgear is the beating heart of power distribution systems. These panels are responsible for the control, protection, and distribution of electrical energy at high voltage. Each component in the switchgear plays a critical role in ensuring the system operates correctly and safely.

Main Components of High-Voltage Switchgear

- 1) Busbars Copper or aluminum conductors with a defined cross-section that distribute electrical current inside the switchgear.

- They come in different configurations such as single-ended, double-ended, and ring (loop) busbars.

- 2) Power Circuit Breakers

- Used to connect and disconnect current under both normal operating conditions and fault conditions.

- Common types include oil, air, vacuum, and SF₆ gas circuit breakers.

- Their role is to protect downstream equipment and the network.

- 3) Current and Voltage Transformers (CTs & VTs)

- Current Transformer (CT): Steps down high current to a lower, proportional current so it can be connected to metering and protection devices.

- Voltage Transformer (VT/PT): Steps down high voltage to a safe level for measurement and protection.

- 4) Protective Relays

- Used to detect different types of faults such as short circuits, overloads, ground faults, and more.

- After detecting a fault, they send a trip command to the circuit breaker.

- 5) Measuring Instruments

- Devices such as ammeters, voltmeters, frequency meters, etc., used to measure the electrical parameters of the network.

- 6) Command and Control Devices

- Used to control and monitor the switchgear.

- Includes items such as control switches, contactors, auxiliary relays, and related components.

- 7) Cables

- Used to connect different equipment to each other and to the external network.

- Cable material and cross-section are selected based on the required current and voltage.

- 8) Switchgear Enclosure

- Built from metal and insulating materials, and responsible for protecting both internal equipment and personnel.

- Must have an appropriate protection rating against water and dust ingress.

Other Auxiliary Components

- Battery: Used to supply power to control and protection equipment during a power outage.

- Battery Charger: Used to charge the battery.

- Control Panels: Used for remote control and monitoring of the switchgear.

Introduction to Low-Voltage Electrical Panels and Their Types

Low-voltage electrical panels are among the most common and widely used industrial panel types, with operating voltages up to 1,000 volts. Inside the cabinet, various components are installed, including different kinds of switches, breakers, relays, and more.

Each of these components functions like a part of a well-organized system and has a specific role. A low-voltage panel consists of the equipment below, and anyone who intends to build this type of panel should be familiar with its parts, applications, and key characteristics.

- Types of fuses in electrical panels – Fuses are among the most important panel components and are typically used when the current exceeds the allowable limit. In that situation, they interrupt the circuit current. In reality, fuses contain a wire element that breaks or melts when exposed to overload. Using fuses is essential in all electrical panels.

- MCB (Miniature Circuit Breaker) – Like fuses, MCBs disconnect power when the network faces an overload. A key difference is that MCBs are generally more sensitive than fuses. They are also considered more reliable because they operate using thermal or thermal-magnetic mechanisms.

- Contactor – A contactor is a device used for remote switching in a control circuit. Its role is to connect and disconnect various single-phase and three-phase devices and electrical equipment used in industry.

- Digital three-phase phase control (phase monitoring relay) – This device is used to protect electric motors in low-voltage panels.

- Single-phase and three-phase bimetal relays (thermal overload relays) – These devices are used in electrical panels as a protection system for three-phase motors against overload conditions at relatively low voltages. They typically consist of two different metals; when excessive heat occurs in the circuit, one metal bends more than the other, causing the device to trip and disconnect current.

- MPCB (Motor Protection Circuit Breaker) – MPCBs are a specialized type of protective device. They provide fault protection (magnetic) and overload protection (electronic), and their role can vary depending on the panel design. They also provide motor safety features such as overload protection, fault indication, automatic re-closing, phase imbalance protection, phase loss protection, and more.

- Double push-button (start/stop station) – These push buttons are used to start and stop a motor. In other words, they perform both the circuit connection and disconnection functions.

- Limit switch – A limit switch is a type of safety interlock used to control the operation of different machines and systems.

- Micro switch – A micro switch is a switch used to open and close electrical current in electrical circuits.

- Timer – Timers are used to control circuits, including timing a specific operation or setting the delay between actions in control circuits within industrial panels.

- Voltage protector (surge/overvoltage protection device) – The role of a voltage protection device is to divert excess electrical energy during an overvoltage event and transfer it to ground through the grounding conductor.

- Electronic float controller – This device prevents a motor from running dry and continuously monitors the liquid level.

- Types of sensors – Various sensors such as temperature, humidity, pressure, and others are used in low-voltage panels, each with specific applications. These sensors also come in different types, including inductive sensors, capacitive sensors, optical sensors, and more.

Low-Voltage Switchboard Design

- 1) Determine the switchboard type

- 2) Draw the switchboard diagram

- 3) Estimate the switchboard cost

Key factors in low-voltage switchboard cost estimation

- The cabinet dimensions required to accommodate the various elements inside the panel

- The quality, type, and quantity of the installed equipment and components

- Labor costs for manufacturing and assembling the low-voltage switchboard

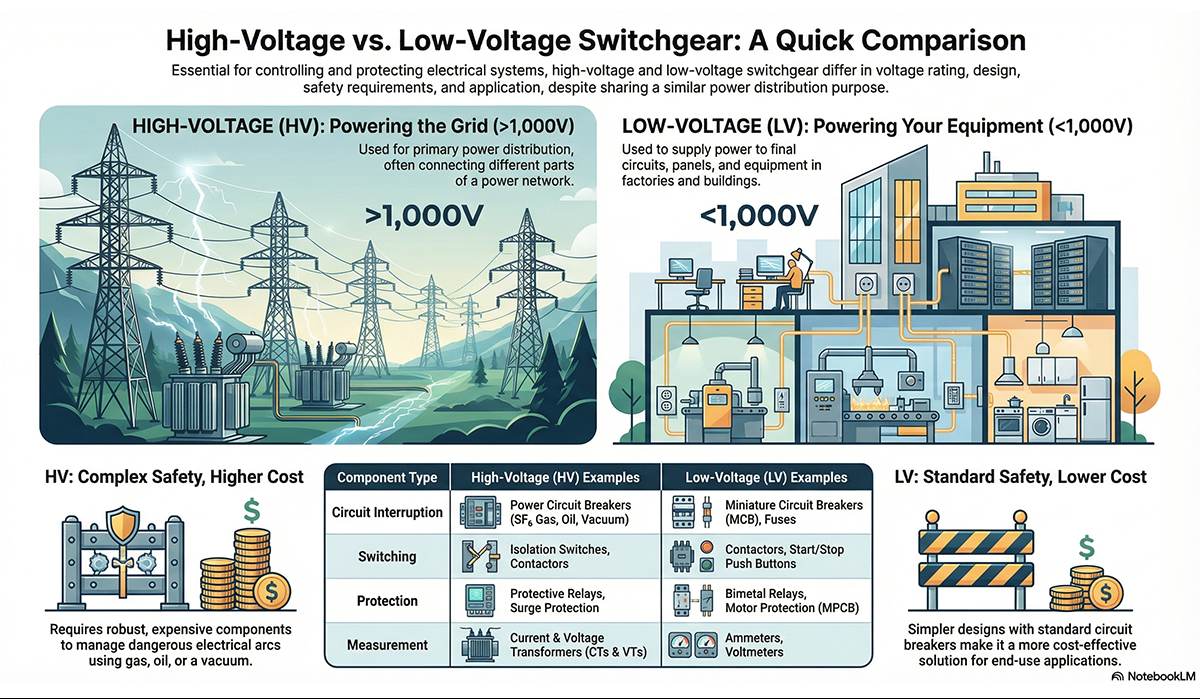

Differences Between HV and LV Switchboards

Both high-voltage (HV) and low-voltage (LV) switchboards are part of power distribution equipment, contain overload protection devices, and often function as service entrance equipment. So their overall purpose is similar. However, they differ in several important ways, which are summarized below.

- Voltage

- Safety

- Cost estimation

- Applications

Voltage

One of the main differences between HV and LV switchboards is voltage rating. HV switchgear voltage ratings cover a wider range and can vary from a few volts up to thousands of volts.

For example, low-voltage switchboards operate up to 1 kV, while medium-voltage and high-voltage switchboards can have voltage ratings up to 366 kV and above.

On the other hand, switchboards intended for lower voltages are often designed below 600 V. For example, a typical residential panel may be 120/240 V, while commercial and industrial installations may use panels rated up to 600 V.

Safety

In HV switchgear, the breaker is designed to handle electrical arcing, and more complex insulation methods are used, such as air, gas, oil, solid dielectrics, and even vacuum.

In LV switchboards, some of these arc-flash extinguishing techniques may not exist, because certain industry requirements may not be mandatory.

Although LV switchboards do not necessarily require arc control in the same way as HV, they may still include features that reduce arc-flash effects, such as arc-resistant switchgear designs.

Cost estimation

HV switchboards have more complex and robust structures, so they generally cost more than LV switchboards. For example, compared to fixed-mounted low-voltage MCCBs used in LV panels, HV switchgear may use withdrawable (draw-out) breakers, which are typically more expensive.

Applications

LV switchboards are commonly used to control, protect, and isolate electrical equipment or circuits in residential and industrial environments such as factories, power plants, and mines. As a result, they are often installed on the secondary side of the incoming transformer, where they supply power to panels and other equipment.

In contrast, an HV switchgear lineup is typically used for power distribution within a building or structure, so it may be used in residential and commercial environments such as homes, offices, and shops.

HV and LV switchboards differ in many aspects, including voltage levels, design, application, and cost. Overall, this information should give a clearer view of the differences between these two switchboard types. Most importantly, with this understanding, you will be in a better position to choose and purchase the right switchboard for your needs.

Conclusion

Selecting between high-voltage and low-voltage switchboards comes down to voltage rating, safety requirements, cost structure, and where the equipment sits in your distribution system. If you are planning an upgrade, expansion, or optimization project, define your voltage level, protection needs, and operating environment first, then choose switchgear and components that match the real risks and performance expectations.

If you want expert help choosing the correct switchboard type and key components for your site, contact a qualified engineering or panel-building team, share your project requirements, and get a solution designed for safety, reliability, and long-term operation.