Review of Industrial Electrical Panel Components

Industrial control panels are offered in various shapes and sizes to the market and require specialized individual handling. These electronic devices operate at 600 volts or less and consist of power and control circuits. Their purpose is to control factory equipment and provide a single operational base for the process control engineer. Depending on use, ICPs are available in open or closed form.

If you are looking for more information about topic All Types of Electrical Panels, it is recommended not to miss reading this article.

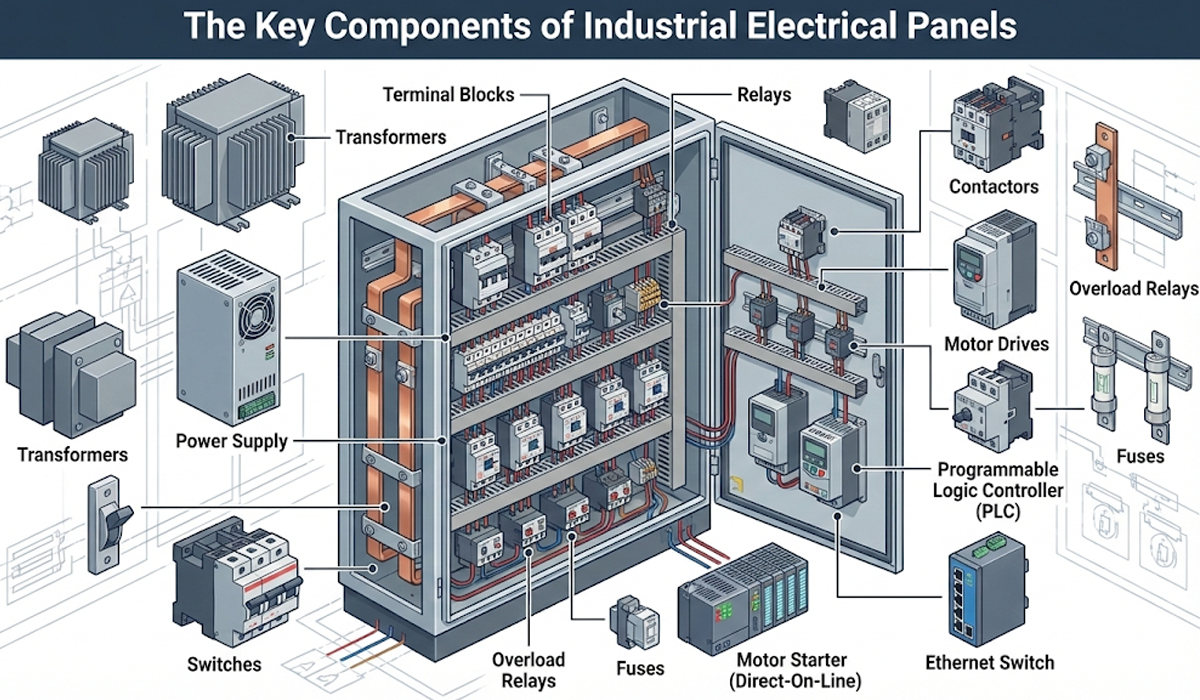

The Key Components of Industrial Electrical Panels

- Transformers

- Power Supply

- Circuit Breakers

- Switches

- Terminal Blocks

- Relays

- Contactors

- Overload Relays

- Fuses

- Motor Drives

- Motor Starter

- Programmable Logic Controller (PLC)

- Ethernet Switch

Electrical control panels are an essential part of any automatic production process. At a basic level, control panels house various electronic devices that provide signals to guide the operation of equipment and machines.

If you are looking for more information about topic Industrial Electrical Panel, it is recommended not to miss reading this article.

While control systems are a fundamental aspect of electrical engineering, many people are not aware of the key control panel components required for safe and reliable operation. The components that make up an industrial electrical panel are:

Transformers

Transformers increase or decrease AC voltage between circuits. A common application for a transformer in an industrial control panel is converting 480 V AC input to 120 V AC, so that other panel control devices can use it.

Power Supply

A power supply converts alternating current (AC) voltage to direct current (DC) voltage. In a control panel, the power supply typically converts 480 V AC or 120 V AC to 24 V DC.

Circuit Breakers

Circuit breakers protect the electrical circuit from damage by detecting excess electricity and opening or breaking the circuit to stop flow.

If the information related to topic Industrial Electrical Panel Components was interesting and informative to you, researching topic Circuit Breakers can be very engaging.

Switches

While a disconnect switch can be manufactured in various styles and shapes, the overall purpose is to fully disconnect the control panel from its power source. A common use of a disconnect switch is to cut panel power for maintenance or repairs and for emergency stops.

If the details you gathered about topic Industrial Control Panels were interesting and insightful, you may find diving deeper into topic Switchgear Secrets equally captivating.

Terminal Blocks

These devices are connection points that can join two or more wires together. Terminal blocks can be placed side by side on a strip to direct power from one source to various devices in the control panel.

If you are seeking more detailed information on topic terminal blocks, this article provides a comprehensive overview. It is highly recommended for anyone who wants to deepen their understanding.

Relays

A relay is an electromechanical or electronic switch that turns a device on or off by making or breaking contact. Relays typically allow low currents to activate higher currents.

Contactors

Similar to a relay, a contactor turns electrical current on or off. The main difference is that contactors are generally larger and used in higher-current applications. A common use of contactors is controlling electric motors, which often have high current loads.

Overload Relays

An overload relay protects electric motors from overheating and prevents the motor from drawing more amperage than its rated load. This can occur when the motor circuit is protected by a circuit breaker rated higher than the full-load current of the motor.

Fuses

A fuse is a safety device that protects the electrical circuit from overload by very high current. When a fuse operates (blows), it becomes an open circuit and must be replaced.

Since buses play a crucial role in the production of electrical panels, obtaining more information about Fuses can be very important and essential.

Motor Drives

There are various types of motor drives, each performing a specific purpose. The general function of a motor drive is to start a connected motor. Common motor drives used in control panels include VFDs (Variable Frequency Drives), servo drives, and soft starters.

Motor Starter

A motor starter is a device that combines a contactor and an overload relay to control the electrical output to a motor when starting and also protect against overload while the motor is running. It often includes a modular assembly and a manual on/off switch.

If you are looking for more information about topic Motor controller, it is recommended not to miss reading this article.

Programmable Logic Controller (PLC)

A PLC is an industrial computer specifically designed to control production processes, such as moving equipment and machines on an assembly line. PLCs are programmed using a specific computer language and are designed to operate in factory conditions that may include high noise and vibration levels. To control equipment and processes, PLCs monitor sensor input statuses to control outputs like motors, HMIs, valves, lights, and solenoids.

Ethernet Switch

An industrial Ethernet switch enables communication between devices inside the control panel—like PLCs, VFDs, and HMIs—and devices outside the panel such as other control panels, SCADA systems, or information systems.

Components of Building Electrical Panels

- Main Switch (Miniature)

- Fuses

- Miniature Circuit Breakers (MCB)

- Residual Current Circuit Breaker (RCCB)

- Relays

- Contactors

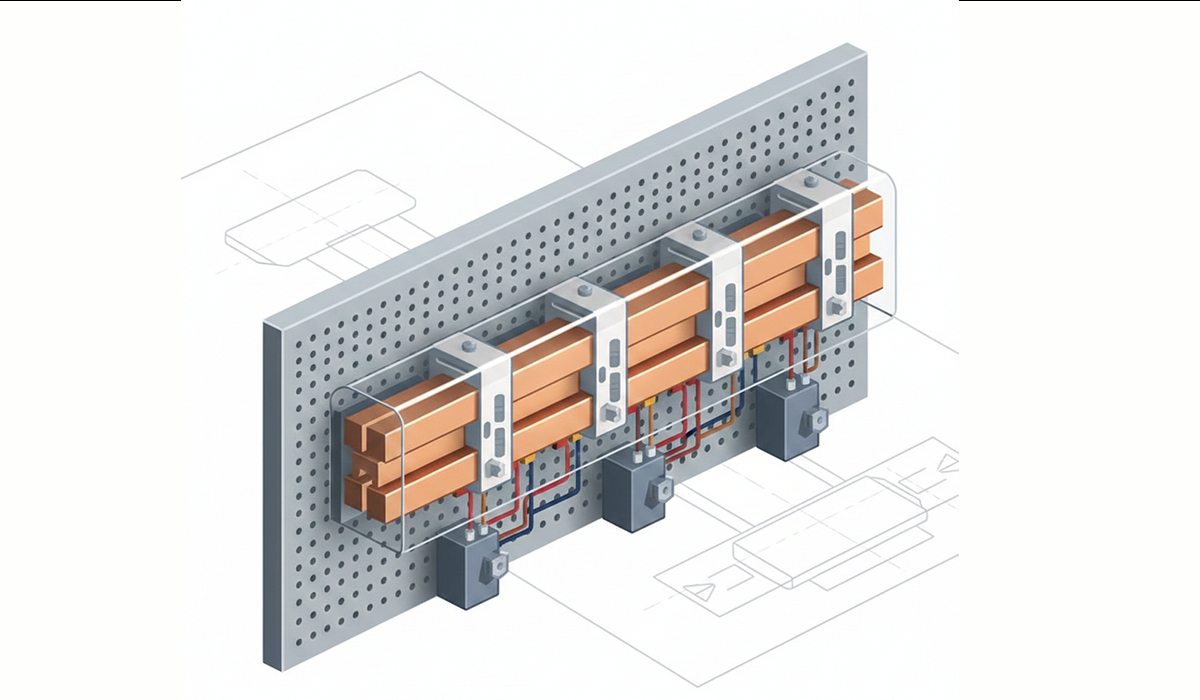

- Bus Bars

- Buses

- Indicators

- Measuring Equipment

Building electrical panels, as the beating heart of a building’s electrical system, play a vital role in distribution, control, and protection of electrical current. These panels consist of a set of electrical equipment designed to safely distribute electricity to different parts of the building and protect circuits against overload, short circuit, and other hazards.

Main Switch (Miniature)

Used to turn on and off all electrical circuits of the panel.

Fuses

Prevent excessive current increases and disconnect the circuit.

Miniature Circuit Breakers (MCB)

Function similar to fuses but allow adjustable trip current.

Residual Current Circuit Breaker (RCCB)

Prevents electric shock to people.

Relays

Used for control and protection of more complex circuits.

Contactors

Used for switching high-power circuits.

Busbars

Copper or aluminum conductors for distribution of electricity within the panel.

Buses

Conductors that connect all panel components to the power source.

Indicators

Used to display the status of circuits and equipment.

Measuring Equipment

Used to measure current and voltage.

Types of Building Electrical Panels

- Main Electrical Panel

- Common Area Panel

- Unit Panels

- Elevator Panel

- Low-Voltage Panel

Main Electrical Panel

The main electrical panel is the primary entry point for electricity into the building, acting as the central distribution hub. It receives power from the utility and distributes it to various parts of the building, with protective devices like fuses or circuit breakers to prevent overloads and potential hazards.

Common Area Panel

The common area panel provides power for lighting systems and outlets in shared spaces such as hallways, lobbies, and staircases. It ensures proper lighting and electrical supply in public and communal areas within the building.

Unit Panels

Unit panels supply electricity to individual residential or commercial units. Power is drawn from the main panel and distributed to specific circuits for each unit, offering separate control and enhanced safety through individual circuit breakers.

Elevator Panel

The elevator panel supplies power to the elevator system, ensuring proper operation of the motor, control systems, and emergency features. It keeps the elevator functioning smoothly and safely throughout its use.

If the content related to topic Industrial Electrical Panel was both interesting and helpful, further study of topic Elevator Control Panel could be just as fascinating.

Low-Voltage Panel

The low-voltage panel powers control systems operating at lower voltages, such as fire alarms, security systems, and telecommunications. It isolates these sensitive systems to prevent interference and protect them from power surges.

Important Notes in Selecting and Installing Electrical Panels

- Panel Capacity: The panel must be matched to the building’s electrical load.

- Type of Equipment: Equipment must comply with the application and safety standards.

- Correct Installation: Must be carried out by specialized individuals according to electrical standards.

- Routine Maintenance and Service: To ensure correct operation.

Finally

The building electrical panel is a vital component of the building’s electrical system. Knowing its various components and how they function helps you choose and install the most suitable electrical panel for your building.

Industrial control panels are also defined as a set of two or more power circuit components, control circuit components, or any combination thereof. These parts typically include switches, terminal blocks, contactors, motor drives, transformers, overcurrent protective devices, etc.