General Definition of an Electrical Panel

A general definition of an electrical panel: a large panel, frame, or enclosure in which switches, overcurrent protective devices, and other electrical equipment are installed on, inside, or behind it.

The role of an electrical panel is to allow the incoming electrical supply to be divided into smaller circuits for distribution, and to provide switching, current protection, and (optionally) measurement for these separate circuits.

In general, electrical panels can distribute power between transformers, other panels, control equipment, and ultimately to the loads of individual systems.

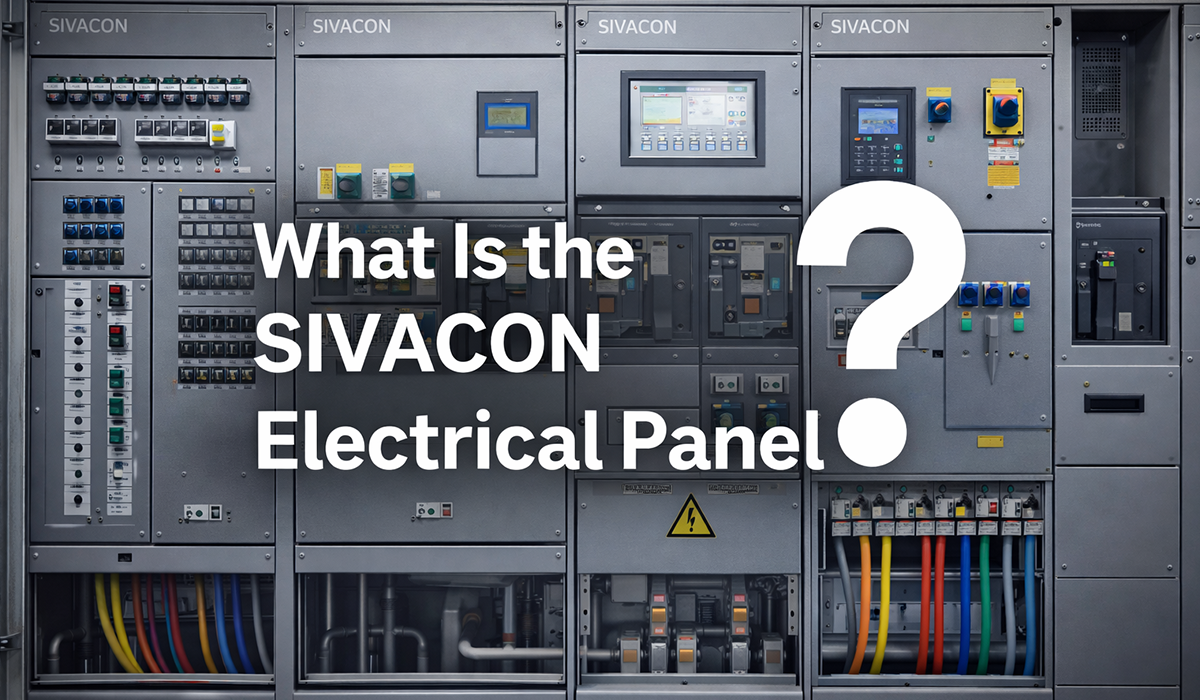

Electrical panels are designed and manufactured in various types. One of the widely used models is the SIVACON panel. Below is useful and concise information about this type of electrical panel.

If the information related to topic Sivacon was interesting and informative to you, researching topic Busbars in Electrical Systems can be very engaging.

Overview of the SIVACON Electrical Panel

The Sivacon electrical panel is a modular panel that flexibly meets your needs with a high level of reliability. From a technological perspective, SIVACON panels offer a smart combination of cost-effective design and high quality.

Their practical advantages include being a comprehensive, versatile, safe, compatible, and easy-to-operate source for meeting electrical distribution needs.

These panels are commonly found in large and high-consumption facilities such as power plants, oil companies, electrical substations, and large factories, and they require ample installation space.

If you are looking for more information about topic SIVACON Panels, it is recommended not to miss reading this article.

Types of SIVACON Panels

- SIVACON electrical panels are produced and offered in two main configurations: sliding type and fixed type.

- The sliding type is more widely used than the fixed type because it helps prevent entire system shutdowns during maintenance.

- In the sliding panel structure, if a fault occurs in any section of the panel, that section can be slid out of the circuit for service.

- This design allows the other sections of the panel to continue operating without interruption, which is a major advantage over fixed panels.

Features of the SIVACON Electrical Panel

- One of the most common panel designs that requires more installation space than conventional panels.

- Its mechanical assembly is complex and its electrical coupling is done through busbars.

- Available in various sizes according to customer requirements.

- The output feeders that supply end-use loads are structured inside the panel as draw-out units (“cassettes”), where each cassette feeds a separate load.

- While the installation cost is relatively high, the panel offers top-level safety and performance.

- Because each cassette functions like its own panel, the number of internal devices and assembly requirements is greater than many other panel types.

- These panels are strong, aesthetically designed, and flexible in terms of configuration.

FAQ