Metal punching and notching machines have two key functions: One is punching holes in steel up to a thickness of 2 mm, and the other is notching, i.e., cutting V- or U-shaped notches into sheets, bars, and other metals. Due to their high efficiency, metal punching and notching machines are used in various industries such as switchgear factories, elevator factories, extraction industries, and many more. The robust structure of these machines prevents continuous bouncing during operation.

In this article, you will get a comprehensive overview of metal punching and notching machines, their functioning, and the different machine types. You will learn about the basic punching processes in sheet metalworking, as well as notching, and understand the role these processes play in modern metalworking. Additionally, the article introduces various types of metal punching and notching machines and shows how to select the right machine type based on material, capacity, and application.

Prefer listening? You can play the audio version of the rest of this article below.

Understanding the Processes of Metal Punching and Notching Machines

What is Metal Punching?

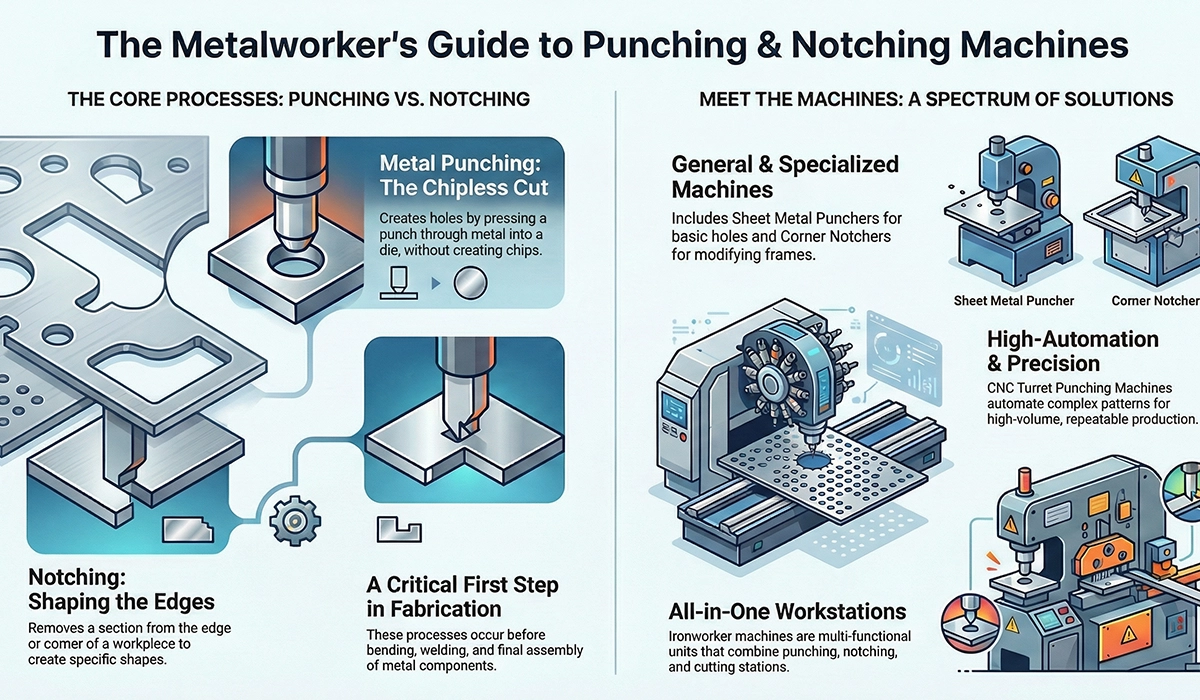

Metal punching is a mechanical cutting process in sheet metalworking where a workpiece is processed using a punch and a die in a single stroke. This creates holes and cutouts without removing material. The difference between punching and drilling is that drilling creates chips, while punching is a chipless and much faster process.

Laser cutting is based on a thermal process, while metal punching and notching machines operate without a heat-affected zone. This is an important advantage of punching because it is especially economical for series production, repeated hole patterns, and standardized shapes. Metal punching is widely used in switchgear manufacturing, elevator construction, busbar processing, and general sheet and metalworking.

What is Notching?

Notching refers to the process where a section is removed from the edge or corner of a sheet or profile to create specific shapes or notches. This process is commonly used to cut corners, for example, in the manufacturing of boxes, door frames, or other types of frames.

It is important to note that metal punching and notching machines are crucial in the production process that occurs before bending, welding, and assembly. These steps serve to create the necessary shapes and cutouts in materials. Applications can be found in the manufacturing of switchgear, busbars, enclosures, and steel constructions that require precise formations.

Types of Metal Punching Machines

Next, we will introduce various types of punching machines used in sheet metal processing. However, before that, it is recommended that you become more familiar with our new machine, the Cold Former, for carrying out your professional activities.

Sheet Metal Punching Machine

The sheet metal punching machine punches holes in steel sheets up to 2 mm thick and is suitable for use in switchgear manufacturing, elevator factories, extraction industries, and more. They come equipped with a “laser pointer” that helps users easily find the center of holes and increases punching speed. These machines offer a wide range of dies that can assist various industries. These include round, square, rectangular, ventilation, and other dies.

If you found this article useful, reading an article on topic Punching machine is recommended for more specialized information.

Hydraulic Single-Function Punching Machines

Hydraulic single-function punching machines are powerful tools for punching holes and shapes in metal. With their C-frame or portal design, they offer a stable structure and are ideal for flat bars, plates, busbars, and small profiles. They feature high tonnage, fast tool change, and easy operation, which boosts productivity. These machines are especially suitable for applications in metalworking, switchgear production, and the automotive industry, allowing for precise punching, notching, and cutting.

Suitable for:

- Flat bars

- Plates, busbars

- Small profiles

Advantages:

- High tonnage

- Fast tool change

- Easy operation

Turret Punching Machine

A turret punching machine is an important type of metal punching and notching machine in the manufacturing industry. Also known as a turret punch, this machine is used to punch different shapes and hole sizes into metal sheets. The basic mechanism of the machine involves a punch pressing the workpiece against a die to create the desired hole shape.

CNC Turret Punching Machine

A CNC turret punching machine is essentially a turret punch with integrated CNC control. This allows for very precise and clean shapes and hole patterns to be created. The turret punching machine was already economical, fast, and reliable; however, with the CNC integration, accuracy, efficiency, and repeatability have been significantly improved.

Applications:

- Switchboards

- Perforated plates

- Ventilation patterns, etc.

Advantages:

- High productivity

- Automatic sheet punching

- Integration with CAD/CAM

Ironworker Punching Machines

Ironworker punching machines are multifunctional metal punching and notching machines that combine multiple stations for cutting, punching, notching, and sometimes bending metals like angle, flat, and round steel into a single compact unit. Therefore, this machine is suitable for general manufacturing such as angles, channels, and plates.

Portable and Special Punching Machines

Portable punching machines are compact, mobile tools for creating holes in large or fixed materials (such as I-beams) on-site, while special punching machines are designed for specific tasks, often automated, such as creating unique hole shapes or notches in mass production for industries like the automotive sector. They offer efficiency and precision that exceed those of standard machines. Both prioritize mobility or a specific function over general use and differ from traditional stationary punching presses.

Portable numbering punching machines for metal:

- Ideal for numbering, marking, and for work on construction sites

Special punching machines:

- Designed for processing columns, beams, or specific profiles

Types of Notching Machines

Notching machines typically consist of a sturdy machine frame, a work table, a vertically guided ram, a cutting tool, and a hold-down system. The workpiece is positioned on the table and securely fixed. The ram moves up and down to precisely notch the material. Depending on the application, cutting tools such as blades or punches are used. The hold-down ensures the material stays firmly on the table during the entire process, ensuring clean cuts and consistent processing quality. Metal punching and notching machines thus provide high precision and efficiency when processing sheet materials.

Hydraulic Sheet Notching Machine with Adjustable Angle

The hydraulic sheet notching machine with an adjustable angle can cut angles in the range of 40° to 135°. This versatile metal punching and notching machine provides high cutting accuracy and is capable of cutting both symmetrical and asymmetrical shapes with ease. It is used in many applications where precise notches are required to create joints or fittings.

Corner Notching Machines for Sheets

Corner notching machines with fixed and variable angles are built for everyday use, such as modifying corners on boxes, plates, and frames or performing irregular or one-off tasks. Whether with fixed or variable angles, these machines offer high versatility. Few machines can match the corner notching machine in terms of versatility and durability.

Notching Units in Ironworkers and Integrated Lines

A notching machine for steel is another powerful tool integrated into ironworkers. It allows for cutting corners or slots in plates and angles, a process critical for making joints and fittings. Without notching, steel construction would require additional welding and grinding, which increases both time and costs.

Special Station for Notching in Ironworkers:

In ironworkers, a special station for notching is integrated, allowing precise slots or corners to be cut into steel plates. This station ensures that the notches are done with high accuracy and efficiency, eliminating the need for additional steps like welding or grinding.

Notches on Angles, Channels, Flat Bars:

The notches can be made on angles, channels, and flat bars, which is essential for creating joints and fittings in steel constructions. This process saves both time and costs by eliminating the need for additional welding and grinding.

Specialized Notching for Busbars and Profiles

Notching copper and aluminum busbars is a specialized processing step that is especially important in the production of switchgear and electrical distributions. Metal punching and notching machines make it possible to create specific notches or cutouts in busbars, improving their bendability, clearance, and ease of assembly. These adjustments are particularly important when dealing with complex geometries, connection points, or modifications to cabinet layouts. Through such processing, more precise fits can be achieved, reducing manufacturing and assembly times and enhancing production efficiency.

Applications of Metal Punching and Notching Machines

Metal punching and notching machines are used in many industrial fields, especially in the processing of busbars, switchgear, and electrical enclosures. Through precise punching and notching, busbar holes and slots, as well as sheet doors and sidewalls for switchboards, are made, often with additional functions like locks, hinges, and cable entry points. These machines are indispensable in the manufacturing and customization of components required for power distribution and control.

Industrial Switchgear

Industrial switchgear is designed for various purposes, including automation, power distribution, and specialized applications in fields such as chemicals, oil and gas, and the food industry.

Each switchgear is customized to the specific environmental conditions of a plant. In switchgear manufacturing, busbar holes and slots are frequently punched and notched, along with sheet doors and sidewalls, including locks, hinges, and cable entry points. These tasks ensure the functionality and flexibility of the systems. This article explores the key applications of metal punching and notching machines in industrial switchgear and examines their role in enhancing productivity, safety, and energy management.

If you found this article useful, exploring an article on topic Switchgear Secrets can provide you with more comprehensive information.

Operation, Safety, and Maintenance Basics

Setup and Punching Quality

Correct alignment of the punch and die, proper gap adjustment, and lubrication are critical for punching quality. An incorrect gap can result in inaccurate punching outcomes and a shortened tool lifespan. Lubrication plays a crucial role in reducing wear and extending the lifespan of punches and dies. Punching quality is also highly dependent on proper tool alignment. Misalignment can cause burrs and affect product precision. Regular monitoring of these parameters ensures consistent results and helps avoid machine downtime.

Safety Practices

Safety during the operation of metal punching and notching machines is paramount. Safety guards prevent workers from coming into contact with hazardous machine parts during operation. The two-hand operation and foot pedal safety features ensure that the machine operator remains at a safe distance. An emergency stop system can immediately halt the machine in case of an issue, preventing accidents. Regular training is required to ensure all operators are familiar with safety protocols and know how to operate the machines safely. Personal protective equipment (PPE) such as gloves, goggles, and safety shoes should always be worn.

If this article has been helpful to you, we recommend reading the article on topic Safety Practices and rules for more detailed and accurate information.

Routine Maintenance for Metal Punching Machines

Routine maintenance of metal punching machines includes various aspects. Lubricating moving parts prevents friction and minimizes wear. Regular checks of hydraulic oil levels and ensuring all seals are intact are essential. Inspections should also check for cracks in the machine frame and other signs of damage. Worn punches and dies must be replaced promptly to maintain consistent punching quality. A good maintenance routine extends the machine’s lifespan and reduces unexpected failures.

Investment, ROI, and When to Switch to Automated Punching

Cost Structure of Metal Punching and Notching Machines

When deciding to purchase a metal punching and notching machine, several cost factors must be considered. Initial costs include the machine itself, required tools, and installation. Additionally, operational costs such as tools, energy consumption, maintenance, and operator training must be factored in. A detailed analysis of these costs helps evaluate the investment’s profitability.

Calculating Amortization for Metal Punching and Notching Machines

The amortization of a metal punching and notching machine is determined by comparing productivity and costs against manual processes or external services. Metal punching and notching machines increase production speed, reduce errors, and decrease labor, leading to significant savings. While external services may be useful for small batches, owning a machine is more cost-effective for larger production volumes. Amortization occurs faster when the machine is used regularly and in large quantities, making the investment even more profitable.

When to Choose an Automatic Sheet Punching Machine

For high variety and production volumes, CNC turret punching machines or automatic sheet punching machines are the best choice, as they offer high precision and efficiency. These machines are particularly beneficial when different hole sizes and shapes need to be manufactured in large quantities. For limited and repetitive parts, where constant shape and size are required, hydraulic sheet punching machines are more suitable. They provide a cost-effective solution for smaller production runs where flexibility is not a priority.

Conclusion

Metal punching and notching machines play a central role in modern metalworking, offering an efficient solution for producing precise metal parts. Whether in switchgear manufacturing, elevator construction, or the production of switchgear, these machines boost productivity, improve accuracy, and lower production costs. By choosing the right machine—from sheet punching machines to CNC turret punching machines and specialized notching machines companies can optimize their manufacturing processes and tailor them to their specific requirements.

Regular maintenance and adherence to safety precautions are essential for ensuring a long machine lifespan and operator safety. For businesses that require high production volumes or regular punching operations, investing in their own machine is a cost-effective and efficient long-term solution. For lower production volumes, external metal punching services may be a viable option.

Overall, metal punching and notching machines offer significant advantages for metalworking, enabling businesses to expand their manufacturing capabilities and increase their competitiveness.