Design and implementation of different control systems

Real control systems are usually nonlinear, but if their behavior can be approximated using linear mathematical models, structured design methods can be applied. From a practical point of view, the specified performance requirements of the system determine the design method.

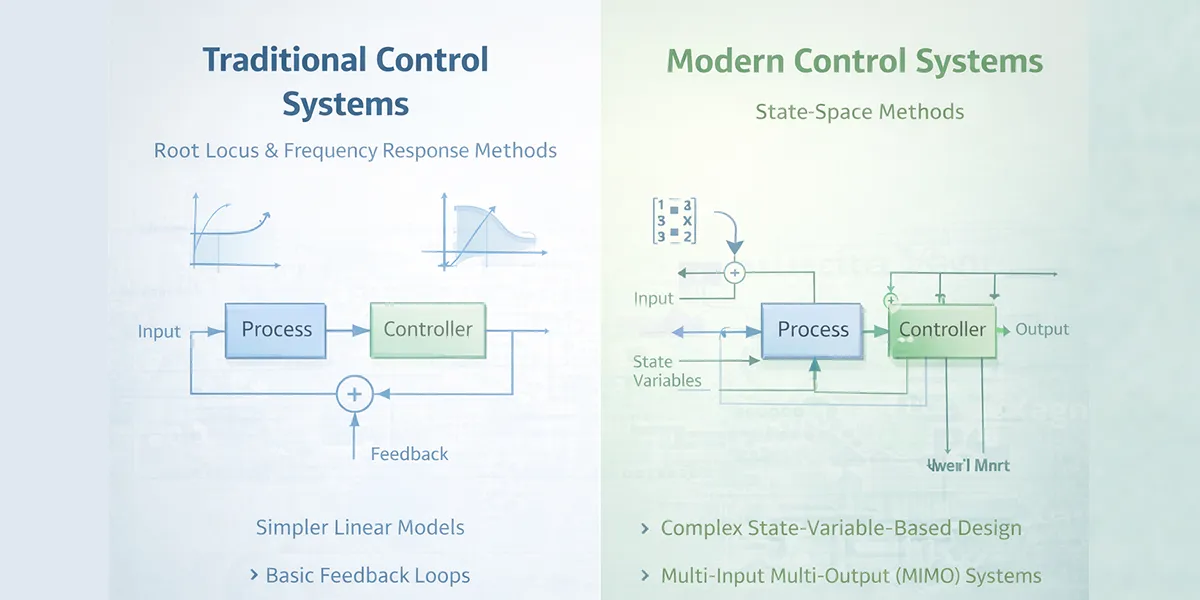

If the performance requirements are expressed in terms of transient response characteristics or frequency-domain criteria, there is no choice but to follow root locus or frequency response methods. If the performance requirements are expressed in terms of indices based on state variables, modern control methods must be used. Designing a control system based on root locus and frequency response approaches is an engineering task; however, in designing a system based on modern control theory (state-space methods), mathematical formulation of the problem and application of mathematical theories are used to solve it. In this case, the system can be multi-input multi-output, and even time-varying.

In modern control theory, you can start from a performance index and constraints imposed on the system and design a stable system using a completely analytical method. You can create a control system that is optimal with respect to a performance index, and this is one of the advantages of this method. Systems that can be designed using traditional methods are usually single-input single-output, linear, and time-invariant systems. By following proven patterns and trial and error, you can satisfy all performance criteria.

After designing the system, test it to see whether the designed system has the desired characteristics or not. If the answer is negative, repeat the design process by adjusting a parameter or changing the configuration until the desired specifications are obtained. Although this design method is trial and error, engineering intelligence and knowledge play an important role in successfully applying this method.

If you are looking for more information about All Types of Electrical Panels, it is recommended not to miss reading this article.

Usually, it is better for the designed system to have as little error as possible in response to input signals. In this respect, the damping of the system must be reasonable. The dynamic behavior of the system should be relatively insensitive to small changes in system parameters. Undesirable disturbances must be properly attenuated. In general, the high-frequency part must be attenuated so that high-frequency noises such as (sensor noises) are attenuated. If the frequencies of noise and disturbances are known, you can use band-stop filters to remove them.

If designing the system is equivalent to choosing among several alternative systems, the selection can be made based on considerations such as overall performance, cost, volume, and weight. In industrial control system equipment, the goal is to design and implement control loops such as temperature, pressure, level, and flow control loops in industrial processes.

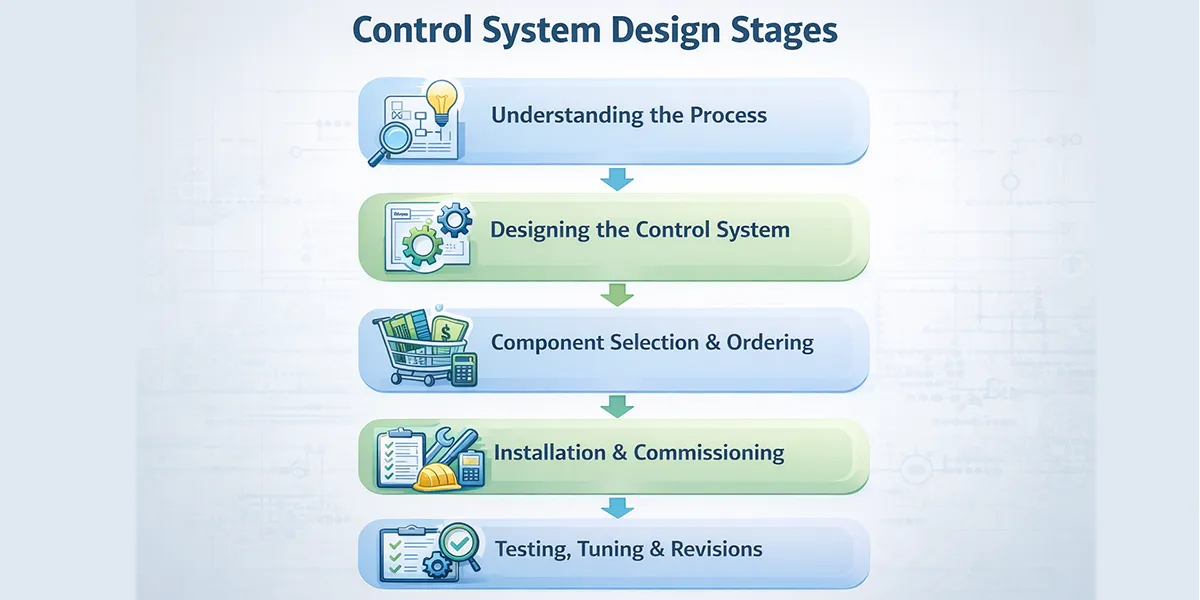

Stages of designing and implementing industrial control loops

In general, the stages of designing and implementing industrial control loops to control a specific behavior of various processes are as follows:

1- Correct and accurate understanding of the process

2- Presenting an initial control plan, including selecting an appropriate controller, designing the controller, and performing theoretical calculations

3- Determining and ordering the required components and parts to implement the initial plan based on required specifications and with economic considerations

4- Revising the plan if some parts are unavailable and replacing them with available parts

5- Installation, commissioning, and testing of components and parts

6- Cold commissioning of the control loop and performing initial tuning

7- Revising the plan if it is incomplete or if problems occur

8- Hot commissioning of the control loop while observing safety considerations and performing final tuning

9- Revising the plan if problems occur

10- Documentation and recording the final specifications of the design and components

In the figures below, the equipment layout for temperature control of a tank is shown. In this layout, the tank temperature is first measured and sent to the controller. By comparing the measured value (Process Value) with the desired value (Set Point), the error signal is determined. Based on the error signal and the performed settings, the controller sends the control command to the control valve, as a result of which the steam valve is adjusted and the tank temperature is corrected.

This article serves as a valuable resource for those seeking detailed information on control loops.

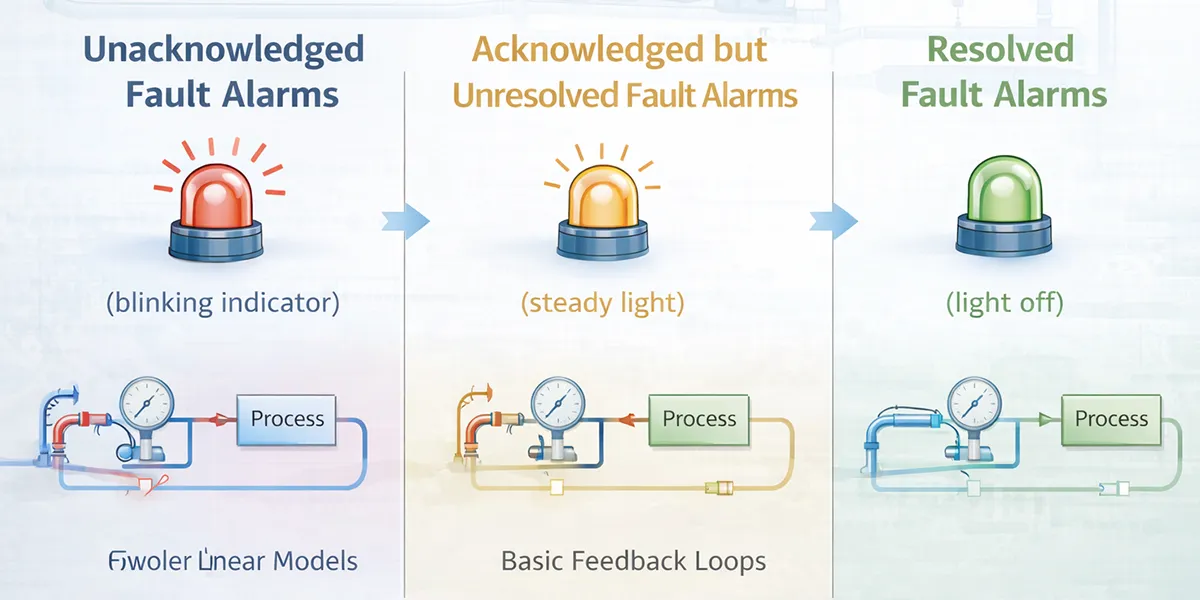

Alarm devices

The occurrence of faults is an inseparable part of industrial control systems. Announcing an alarm when a fault occurs increases your attention and sensitivity in monitoring the correct execution of processes. Fault detection is performed by alarm devices. In an alarm device, the occurrence of each fault is indicated by an indicator.

In general, depending on the fault status, three different alarms are given:

1- Alarms related to unacknowledged faults

In this case, when a fault occurs, the related indicator turns on in a blinking mode. Also, in this case, the fault occurrence can be detected by generating sound.

2- Alarms related to acknowledged but unresolved faults

When the fault is acknowledged but the fault condition still remains, the alarm device changes from blinking to steady illumination.

3- Alarms related to acknowledged and resolved faults

When the fault condition is removed, the steady alarm light turns off. One of the important issues in alarm system design is fault grouping. For example, consider a simple hydraulic system: the occurrence of a fault in each of the three conditions of pump stop, hydraulic pressure drop, and tank level drop is detected by an alarm device.

An alarm caused by pump stoppage leads to an alarm for hydraulic pressure reduction. On the other hand, low hydraulic pressure causes the pump to stop to prevent damage and losses. Similarly, an alarm for low tank level leads to an alarm for pressure reduction and consequently pump stoppage. If these alarms are placed in one group, then the initial alarm is displayed and subsequent alarms are ignored, or they are placed in a queue. Then, without being misled, you can find the root cause of the fault.

If you are looking for more information about Alarm device, it is recommended not to miss reading this article.

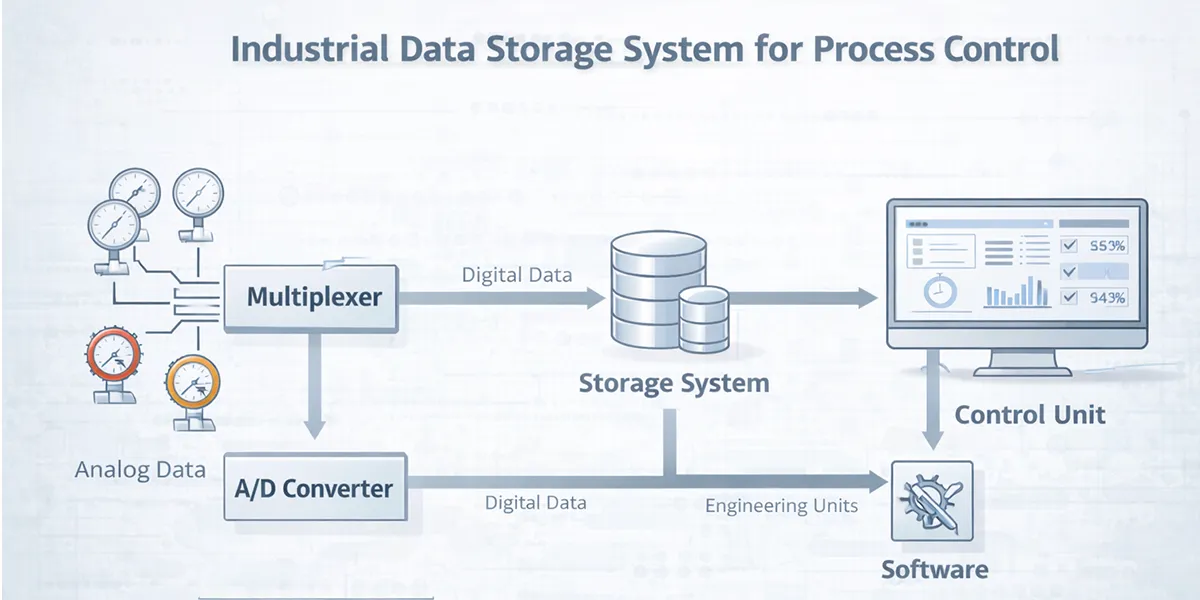

Storing information related to operating variables in automation system design

One of the important issues in automation system design is documenting information related to the design and information related to the running process. In an operating industrial process, a large volume of data and information is produced.

Data and information related to operating variables are used to analyze process performance and determine efficiency and process output. Therefore, storing and recording them is very important. Information storage is usually performed by local computers and the central control room computer. However, if using a computer for process control is not possible or necessary, then industrial systems are used for data storage.

For a comprehensive understanding of What is design automation?, we highly recommend reviewing this article.

Designing an industrial system for data storage

In designing an industrial system for data storage, the following are considered:

1- Storing analog and digital values of a process at normal time intervals

2- Checking alarm conditions and storing the process status at the time of alarm occurrence

3- Recording events and their occurrence times

The resulting data are usually stored on a compact disc and also printed for assurance, thus creating a set of information that can be accessed again.

In the block diagram below, the diagram of a data storage system is shown. In this system, analog data are read through a multiplexer and then sent from a sampling unit. Analog data are usually stored in (A/D) form and, through analog-to-digital converters, are entered into the data storage system. Then, using the control unit software, they are converted into engineering units such as degrees Celsius. To perform this conversion, the upper and lower limits are first specified, and then a linearization subroutine is used.

For a comprehensive understanding of topic X, we highly recommend reviewing this article.

Actuators and final elements

The last element of the control loop of a process in different types of control systems is the final element. A control loop begins with measuring the process output and ends with applying the input command to the process by the controller. The controller command is transmitted to the controlled process by the final element. In industrial processes, valves are usually used as final elements.

Moving the final element, such as opening and closing a valve, requires energy consumption. The command sent from the controller is a control signal that usually does not have the required energy to move the final element. Therefore, this command is amplified and applied to the actuator; then the actuator moves the final element. The final element and its related actuator are usually offered together, and solenoid valves are common examples.

Further exploration of Actuators can be found in the following recommended reading.

In general, control system types are classified as follows:

- Direct Digital Control (DDC)

- Distributed Control System (DCS)

- Programmable Logic Controllers (PLC)

- Fieldbus Control Systems (FCS)

| Features | DDC | DCS | PLC | FCS |

|---|---|---|---|---|

| Control Architecture | Centralized | Semi-Distributed | Centralized/Distributed | Fully Distributed |

| Processing Type | Digital | Semi-Digital | Digital | Fully Digital |

| Data Transfer Rate | Medium | High | High | 31.25 Kbit/Sec |

| Wiring Cost | High | Medium | Medium | Low |

| Expandability | Limited | High (Modular) | Medium | High |

| Fault Isolation | None | Yes | Limited | Yes |

| Diagnostics Capability | Limited | High | Medium | Very High |

| I/O Cards Required | Yes | Yes | Yes | No |

| Maintenance Cost | High | Medium | Low | Low |

| Year Introduced | 1960s | 1960s | 1985 | 1990+ |

| Best Suited For | Simple Systems | Complex Processes | Logic Control | Industrial Processes |

| Programming Complexity | High | Medium | Requires Expertise | Simple (Function Block) |

Direct Digital Control (DDC)

One of the types of control systems is direct digital control, or DDC, which was used from the early 1960s to support analog systems. In DDC systems, the operator communicates with the system via a keyboard and display. In this system, all components including various sensors and actuators are directly connected to the central computer, and all of them receive or send their communication signals from or to the computer. The central computer is capable of processing a large volume of variables, but with excessive growth of information and the creation of complex loops, the speed and efficiency of the computer decreases and causes problems in the system.

Some reasons for the weakness of direct control systems

1- High maintenance cost

2- Shutdown of the entire system in case of a fault in the central processor

3- Due to the use of only one processor in the system, programming it is difficult

4- High wiring and cabling cost

5- Inefficiency over long distances

6- Difficulty of fault detection in the system by technicians

Distributed Control System (DCS)

The distributed control system, or DCS, entered the process control arena in the 1960s and complemented DDC systems. A distributed control system is one of the types of control systems in which operation is distributed instead of being concentrated at one point.

A distributed control system consists of a number of microprocessor modules that work together to control and monitor the operation of a system. Computers are distributed according to the geography of the site; therefore, this reduces installation and wiring costs.

DCS is a computer network, but it differs from existing home or office networks because, in DCS, unlike what is seen in batch processing on office or home computers, real-time processing is involved.

The difference between these two processing methods is in how their programs are executed. In ordinary computers, processing is such that at a given time only one program runs. This program starts complex computations with a fixed and specific set of data and eventually ends with desired results, and when processing is finished the program stops to receive a new command for re-execution with a new set of data.

In the real-time processing method in a distributed control system, processing also starts with a fixed set of data, with the difference that the same program execution is continuously repeated and refreshes the data based on the data from the previous stage. For example, automatic vehicle speed control can be considered a real-time function. Control starts with a fixed speed data, and at each stage the vehicle speed is sampled, and based on the difference from the desired speed, control signals for opening and closing the fuel throttle are applied. A DCS controller also works in this way, meaning it continuously samples hundreds or thousands of controlled systems and repeats calculations based on a defined plan for the relevant systems.

Physical data received from the environment can be divided into two main groups:

- a) Analog data:

This type of data changes continuously. Analog data are analyzed through control loops and software which, depending on need, may include proportional or PID controllers, and appropriate output signals are issued. - b) Discrete data:

Working with them is simple, and based on received signals and logical relations, they turn the input off or on.

If the details you gathered about Distributed Control System were interesting and insightful, you may find diving deeper into Capacitor Switchboard Guide equally captivating.

To receive data from the environment, DCS, like all programmable logic controllers, requires a series of elements such as thermometers, pressure gauges, and ammeters. The values of the elements are converted into electrical signals, and DCS reads them and converts them to digital. The obtained data are used in the following:

- Control loops (feedbacks) for analog control

- Execution of logical programs to issue on/off instructions

- Displaying values on the monitor screen

- Preparing reports on system status

- Announcing danger in abnormal conditions of the controlled system and other operations that can be defined according to the system type

Advantages of a distributed control system compared to older systems

- Expandability and adaptability due to the modular nature of the system

- High control capability because the process control algorithm can be changed easily

- Integration of system functions

- Easy maintenance after installation

- Unlike a centralized system, in DCS, because control is divided, if one module fails, control on other sections continues without any defect; this phenomenon is called Fault Isolation.

DCS systems have expandability. In a central control system, expanding the system requires replacing the central processor and purchasing a more advanced system, but in DCS you can expand control performance by adding control modules.

DCS programming is done in high-level environments. This is unlike PLC controllers, where writing their programs requires familiarity with microprocessor systems.

As previously explained, DCS can consist of many control modules that operate independently and simultaneously; in addition, it has fast communication capability between its modules through communication lines with the data highway in real-time.

If the information related to distributed control system was interesting and informative to you, researching Supercapacitor can be very engaging.

DCS hardware

The hardware of any DCS system can be divided into the following general components:

- Controller and processor unit

- I/O interface circuits

- Communication interface channels and circuits

- Redundance (backup)

- Diagnostics (fault finding)

DCS controller and processor unit

The controller and processor unit is used to implement control algorithms on appropriate inputs and outputs to operate the relevant process. Due to the need to execute complex and detailed algorithms in a small time unit, the necessity of using a powerful processor in this section is evident.

Implementing these algorithms requires special simulation and testing equipment, sufficient mastery of machine language or application languages of the used processor, all of which make the use of units based on Intel series processors and cards based on PC architecture increasingly justifiable.

DCS I/O interface circuits

These units are responsible for receiving information from transducers and sensors or applying results from control logic to other components of the control system such as actuators, valves, and so on. In a large control system, these units must at least have the following capabilities:

- Full isolation

- Minimum adjustment capability

- Internal fault detection and assurance of correct operation by the unit itself

- Ability to communicate with the main processor

- Ability to implement some preprocessing

- Online replacement and fault finding

- Ability to be used as backup

- Acceptable sampling speed

- Acceptable resolution and accuracy in analog-to-digital converters

Considering these needs, using processor-based circuits in such units is also inevitable. However, due to the limited scope of operation of each unit, it is possible to use less powerful or specialized processors in them. One of the major issues in these units is implementing full isolation.

In digital types, this isolation is possible using one of the simplest methods, namely Opto Isolation, but in analog types, due to the diversity and expected accuracy of such systems and also the self-adjusting capability of these components, the discussion becomes somewhat more complex and difficult.

Communication interface circuits in a DCS

One of the most important and at the same time most complex parts of a DCS system is its communication interface circuits. These networks are divided into different sections. Among these sections, the following can be mentioned:

- Communication network between I/O cards and processor and controller units

- Communication network between different processor and controller units

- Communication network between HMI equipment and controllers

- Communication network between DCS systems

Backup (Redundance) in control systems

One of the important topics in control systems is operational safety and system availability over time. For this purpose, Redundance systems are used. This system is implemented at all levels of system hardware such as I/O units, communication networks, power supplies, and so on, depending on the nature of the process and its security level.

Practical implementation of Redundance units is another major challenge of large systems, because, due to the real-time nature of the sections, components must operate in such a way that during replacement no shock is introduced to the system, and replacement is hot in service, and at that moment all information and performance of other components are available. This requires complete information communication between these components, and also different replacement mode conditions must be precisely defined for the system.

Fault finding or debugging (Diagnostics) in DCS systems

Another matter that must be considered in building and implementing a DCS system is automatic fault finding and self-diagnostics in such systems. These diagnostics must include all hardware sections such as controller units, I/O cards, communication networks, HMI equipment, and so on. For this purpose, using specific algorithms and applying various measures in hardware design, you can achieve this important goal. Usually, the diagnostics scope of each section must at least include fault detection and notifying the operator or system engineer to resolve it.

- User terminals

- Operator terminals

This part is the interface between the operator and DCS. Data on the display are reviewed, and the operator, based on this information, communicates necessary commands to the system. Information is entered through mouse, keyboard, touch monitors, and operator keyboards. The operator keyboard, which is not seen in ordinary systems, is a keyboard by which pressing each key related to a specific control system action activates specific conditions in the computer and thus performs the related action. In the operator keyboard, each key is for a specific task, and its function is similar to hot keys in ordinary keyboards.

If you are looking for more information about DCS, it is recommended not to miss reading this article.

Engineering terminals

In appearance, they are like operator terminals and differ only in software, but if needed they can also be used in place of them. However, they are usually used for the following purposes:

- a) Settings related to consoles and basic information

b) Changing main and initial information

c) Installing application software for discrete control systems

Engineering terminals, unlike operator terminals, are usually used offline.

Software and standards

Over the past two decades, fundamental activities have begun around standardizing communication protocols globally. The International Organization for Standardization (ISO) initiated this movement with the OSI (Open Systems Interconnection) model in 1978.

How DCS communicates with different systems

In many applications, DCS must communicate with computers and microprocessor systems:

- When connecting and exchanging information with management information system computers

- Connecting and exchanging information with modeling computers

- When connecting with different PLC types

- And in general, communicating with computers that have another type of operating system

Therefore, it is necessary for transmitted information to be translated first. For this purpose, hardware called a Translator Box or Host Gateway is used. This hardware must be programmed for translation. Therefore, these hardware units, depending on the translation type, have different drivers that establish a Master/Slave relationship between themselves and DCS. For example, when connecting DCS or DCS, PLC acts as Master and, through the hardware and a specific driver, exchanges information with the PLC. This issue is very important in terms of coordination when upgrading the control type of a large process to DCS.

If the information related to DCS systems was interesting and informative to you, researching GE Breakers can be very engaging.

Maste and Slave concepts

In a control system, a Server or Master reads inputs, writes to outputs, and requests information from other devices. On the other hand, a Slave or Client provides information to the system and responds. When sensors are connected to the network, they are considered Slave, but if they are programmed to play a central role in a large system, they gain Master capability.

Sample diagram of a DCS system with analog I/O

Sample diagram of a DCS system under the Foundation Fieldbus protocol

Sample diagram of a DCS system under the Profibus protocol

Programmable controller systems (PLC)

In 1985, the American Instrumentation Association, which later the International Electrochemical Commission also joined, began establishing a standard for two-way digital communications between instrumentation and different control systems for process control purposes. To date, only one of the eight designed parts of this standard, titled IEC1158-2, has been completed, which is: “Fieldbus physical layer standard,” which has been available since 1990 and is known as programmable controllers or PLC.

With the creation of fieldbus and its standards as one of the types of control systems, control systems are managed in a fully distributed manner. In addition to enabling signal communication between field instruments on site and the control room, fieldbus also makes it possible to transfer the required power supply for equipment through a pair of wires, which results in significant savings in cabling costs and cable tray supports. Fieldbus is a standard communication protocol between site equipment and the control room. Having the same protocol in a fieldbus network allows products from different companies to be connected and operate in one network.

Further exploration of (PLC) can be found in the following recommended reading.

Field control system (FCS)

Today, the fieldbus system, as one of the types of control systems, has created a revolution in various industries. In addition, this system is known as the next and more advanced version of DCS.

Differences between FCS and DCS

This system has the following fundamental differences compared to DCS:

- DCS is a semi-distributed system, while fieldbus is fully distributed.

- DCS is a semi-digital system, while fieldbus is fully digital.

- Fieldbus is a complete architecture for process control and is less complex than DCS.

- Fieldbus does not need analog/digital cards and interfaces because communications are essentially digital.

- Fieldbus does not need controller (CPU) cards because controls are performed in field devices.

- Fieldbus does not need a data gateway.

- The benefit of fieldbus is in reducing control room equipment such as I/O racks and conditioning cards. It should be noted that Fieldbus DCS is more valuable than a stand-alone fieldbus-only system.

This article serves as a valuable resource for those seeking detailed information on Field Control Station Hardware.

Advantages of FCS field control systems

Lower price of FCS compared to DCS

An FCS system has a lower initial cost than a similar DCS. Eliminating wiring, field instruments, and control room equipment that were typically used in DCS contributes to this cost reduction. It also brings increased information such as diagnostics information and higher accuracy through digital communications.

Fewer instruments

Many fieldbus transmitters are multi-variable, such as two-channel temperature transmitters that calculate two temperatures and send both in real time.

Diagnostics capability

Digital communications enable access to structural information, transmitted data from field instruments, and fault details from the control room. Automatic diagnostics of each field instrument quickly reports errors or problems and enables rapid viewing of faults of different devices even before any damage occurs. Hardware faults such as sensor and actuator faults, as well as software faults such as configuration faults, can be reported and resolved without the need for manual system troubleshooting. Therefore, operators immediately determine, without going to the field, whether a problem in the process is related to field components or not.

Due to the digital nature of signals, system reliability increases through improved diagnostics.

Unlike DCS, the fieldbus system is completely digital from the transmitter to the digital input of a control valve. The presence of digital signals at the end of the control loop enables sending very accurate and complex data to the process. Fieldbus communication cables can extend hundreds of meters without noise or common distortions in analog communications. In addition, computational or control variables exchanged between function blocks include, besides value, a status containing information about signal limits and its quality.

Simpler and easier use

Configuration of all components using the function block method is done in one way, and there is no need to train different programming methods or programming languages, because all manufacturers, regardless of what device they have used, use a similar function block. For example, a temperature and pressure transmitter from different manufacturers operates based on similar fundamentals, which reduces complexity and operator training. In this system, all instruments are connected through a pair of wires that also provide electrical power and communicate and transfer required information through this path.

Suitable data rate

The data transfer rate in this system is 31.25 Kbit/Sec. Although it is not high, it is suitable for controlling chemical processes. It should be noted that in most systems, even DCS, for Emergency Shutdown systems, a system other than the main system, usually PLC with better speed, is used.

Components of a fieldbus system

In a fieldbus system, connecting parts placed in the working field is simple. Usually, each part can be connected and wired in parallel with twelve other parts on one bus. Adding parts that make the system scalable is also easy. The system can also be expanded to meet new requirements. In many cases, parts can communicate with each other without needing an additional interface or cable. Since this system is open, various products from different manufacturers capable of connecting to this network are available.

Conclusion

Industrial control systems can be designed using traditional methods such as root locus and frequency response, or using modern state-space approaches based on state variables and performance indices. Successful implementation requires a clear understanding of the process, careful selection of components, systematic commissioning, and thorough documentation. Key practical considerations include error reduction, reasonable damping, disturbance and noise attenuation, and robust behavior against parameter variations. For industrial projects, choosing the right architecture (DDC, DCS, PLC, or FCS) should be aligned with performance needs, reliability, and economic constraints.