In industrial environments, optimizing energy consumption and ensuring optimal equipment performance are of paramount importance. One of the key solutions for achieving these goals is the use of capacitor banks. A capacitor bank, by compensating for reactive power, helps improve power factor, reduce energy losses, and extend the lifespan of equipment. This not only reduces electricity costs but also ensures the reliable and stable operation of electrical systems. In this article, we will discuss the necessity of capacitor banks and the reasons why every industrial unit should use them.

If you’d rather listen than read, feel free to play the audio file below for the rest of this article.

Increased Electricity Costs and Heavy Penalties

Failure to use capacitor banks in industrial electrical systems can lead to increased electricity costs and heavy penalties. When the power factor is low, there is an excess consumption of reactive power, which not only increases energy losses in transmission lines and equipment but may also result in penalties imposed by power companies for unnecessary reactive power consumption. These penalties are typically added as extra charges on the electricity bill. Installing a capacitor bank can effectively address these issues and reduce extra costs.

The financial impact of low power factor is often underestimated. Beyond direct penalty charges, a poor power factor forces the upstream network — including the utility transformer, main cables, and switchgear — to carry a higher apparent current than the active load alone would require. This means that the existing electrical infrastructure is being consumed at a faster rate, shortening maintenance cycles and potentially requiring earlier capital replacement. A properly sized capacitor bank eliminates this hidden cost by reducing the reactive component of current and allowing the full capacity of existing infrastructure to be directed toward productive work.

| Financial Impact | Cost Factor |

|---|---|

| Utility companies bill extra charges when reactive power consumption exceeds the permitted threshold | Reactive Power Penalties |

| High reactive current increases I²R losses in cables, busbars, and transformers, wasting energy as heat | Transmission Line Losses |

| Oversized apparent current accelerates insulation aging and shortens equipment replacement cycles | Premature Infrastructure Wear |

| Low power factor requires larger cable and switchgear ratings for new installations, raising capital expenditure | Higher Installation Costs |

For a comprehensive understanding of capacitor switchboard systems, we highly recommend reviewing this article.

Reduced Lifespan of Electrical Equipment

One of the other reasons that emphasize the necessity of capacitor banks is the reduced lifespan of electrical equipment. The absence of a capacitor bank and the presence of excessive reactive power can put a heavy strain on electrical equipment. Inductive loads like motors and transformers generate reactive power, which leads to additional currents and voltage fluctuations. These extra currents cause heat generation and increase the temperature of the equipment, ultimately leading to faster wear and tear and a reduction in their useful life. Installing a capacitor bank to compensate for reactive power prevents these issues, improves equipment performance, and extends their lifespan.

Every degree of additional operating temperature accelerates the degradation of insulation materials in motors and transformers. Industry standards estimate that for every 10 °C rise above the rated operating temperature, the insulation life of a motor winding is roughly halved. When reactive current is allowed to flow unchecked through motor windings and transformer cores, the continuous thermal stress accumulates silently until a failure occurs. Capacitor banks address this at the root cause, keeping equipment temperatures within design limits and preserving the full rated service life of each asset.

| Effect Without Capacitor Bank | Equipment Type |

|---|---|

| Winding overheating, insulation degradation, bearing stress, and reduced motor efficiency | Electric Motors |

| Core heating, increased copper losses, oil degradation in oil-filled units, and shortened service life | Transformers |

| Accelerated insulation aging, higher risk of short circuit, and reduced current-carrying capacity over time | Cables and Busbars |

| Contact erosion from higher interrupting currents, more frequent tripping, and reduced breaking capacity margin | Switchgear and Breakers |

Since busbars play a crucial role in the distribution of power within electrical panels, obtaining more information about busbars in electrical systems can be very important and essential.

Risk of Overvoltage and Equipment Damage

A major issue in electrical systems operating without a capacitor bank is the risk of overvoltage. When reactive power is not controlled within the system, voltage fluctuations and disturbances occur, which can cause serious damage to sensitive equipment. These overvoltages lead to premature wear of devices, sudden failures, and even permanent damage to electrical components. A capacitor bank, by compensating for reactive power, not only improves the system’s power factor but also prevents voltage fluctuations, reducing the risk of damage to equipment.

Sensitive electronic equipment — including programmable logic controllers, variable-speed drives, and precision instrumentation — is particularly vulnerable to voltage transients and sustained overvoltage conditions. A single overvoltage event can corrupt control software, damage semiconductor components, or permanently destroy measurement circuits. The cost of replacing or repairing such equipment, combined with unplanned production downtime, far exceeds the investment required to install a properly designed capacitor bank with appropriate overvoltage protection measures.

If the information on overvoltage risks was engaging and informative for you, gathering more knowledge about high voltage vs low voltage could be very exciting.

Power Loss and Low Machine Efficiency

In electrical systems without capacitor banks, the excess reactive power results in power losses, which add an extra load on machinery. This reduces the efficiency of the machines and increases energy consumption. In such cases, machines require more power to perform routine tasks, which not only decreases system efficiency but also leads to higher wear and tear and more frequent repairs. By using a capacitor bank, reactive power is compensated, the power factor is improved, and the efficiency of machines is increased, resulting in lower energy consumption and better overall performance.

If the information on Power Loss was engaging and informative for you, gathering more knowledge about Harmonics (electrical power)

could be very exciting.

| With Capacitor Bank | Performance Indicator |

|---|---|

| Power factor corrected toward unity; reactive current minimized; active current used efficiently | Power Factor |

| I²R losses in cables and equipment significantly reduced; less energy wasted as heat | Energy Losses |

| Machines operate at rated load conditions; less mechanical and thermal stress; fewer unplanned stoppages | Machine Efficiency |

| Voltage profile stabilized across all load conditions; equipment operates within rated voltage tolerances | Voltage Stability |

If the content related to power loss and machine efficiency was both interesting and helpful, further study of harmonic filter solutions could be just as fascinating.

Unstable Power Network and Frequent Power Outages

An unstable power network and frequent power outages can cause serious problems for industries and buildings. These instabilities are usually due to issues such as excessive reactive power, voltage fluctuations, and added strain on energy transmission equipment. When an electrical system has excessive and uncontrolled reactive power, the extra currents and voltage fluctuations reduce power quality, leading to network instability. This instability can result in frequent power outages and even damage to sensitive equipment.

Installing a capacitor bank effectively compensates for reactive power and prevents voltage fluctuations, improving power quality and reducing strain on the power network.

Network instability has cascading consequences that extend well beyond the immediate electrical infrastructure. In manufacturing environments, unexpected power interruptions can halt production lines mid-cycle, causing material waste and product quality failures. In process industries such as chemical plants and food production facilities, sudden outages can compromise batch integrity, trigger safety shutdowns, and require lengthy restart procedures. The business cost of these interruptions — lost production, scrapped product, emergency labor, and customer penalties — is typically orders of magnitude greater than the cost of installing the capacitor bank that could have prevented them.

If the insights you gained from power network stability were intriguing and informative, exploring industrial electrical switchboards might be of great interest to you as well.

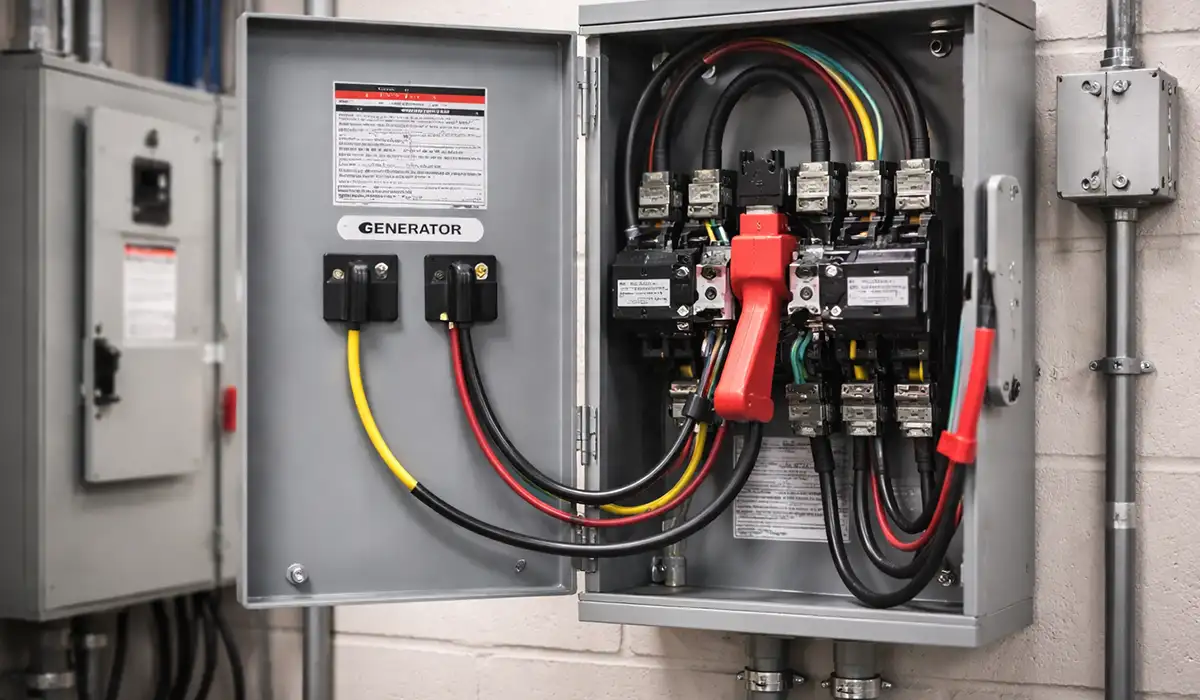

Installation and Commissioning of Capacitor Banks

Capacitor banks are devices used to improve the power factor and reduce energy losses in electrical systems. Their installation is crucial for optimizing energy consumption and reducing costs. The process of installing and commissioning a capacitor bank includes the following steps:

Types of Capacitor Banks

- Fixed: Fixed capacity for constant loads.

- Self-Regulating: Automatically adjusts capacity based on system needs.

- Switching: Manual or automatic switches for engaging and disengaging capacitors.

How to Calculate the Required Capacity

- To calculate the required capacity for a capacitor bank, you first need to calculate the reactive power of the system, then determine the reactive power needed to improve the power factor. The capacitor bank should be sized to compensate for this required power.

Installation Steps

- Assess System Needs: Accurately calculate the reactive power demand.

- Select the Appropriate Capacitor Bank: Choose the right capacitor bank based on the calculations and system requirements.

- Install Equipment: Connect capacitors, switches, and control systems.

- Initial Testing and Settings: Verify the system’s proper operation.

- Monitoring and Operation: Continuous monitoring to ensure the system operates efficiently.

These steps help optimize energy consumption, reduce costs, and extend equipment lifespan.

| Key Requirement | Installation Step |

|---|---|

| Use a power analyzer over a representative period to capture reactive power demand at all load conditions | Assess System Needs |

| Match bank type (fixed, automatic, or detuned) and kVAR rating to the measured reactive power profile | Select Capacitor Bank |

| Follow manufacturer wiring diagrams; ensure correct CT ratio, contactor ratings, and cable sizing | Install Equipment |

| Energize in stages; verify power factor controller response; check for harmonic resonance before full load operation | Initial Testing |

| Log power factor, temperature, and switching frequency regularly; schedule periodic capacitor and contactor inspections | Monitoring and Operation |

If the information about installation and commissioning was valuable and interesting to you, researching electrical panel components could be just as captivating.

Conclusion: The Necessity of Capacitor Banks

Installing a capacitor bank is an effective solution for enhancing the performance of industrial and commercial electrical systems. The benefits of installing a capacitor bank include reduced electricity costs, extended equipment lifespan, improved power factor, reduced energy losses, and prevention of power network instability. This system is especially important in variable loads and systems with excessive reactive power, as it helps optimize energy consumption and reduces pressure on the power grid.

For optimal performance and energy cost reduction, the installation of a capacitor bank in electrical systems is essential. Selecting the right type and capacity of capacitor banks based on the system’s needs can result in significant savings and improved efficiency.

If you enjoyed learning about capacitor bank necessity, investigating types of electrical panels might also offer a similarly engaging and informative experience.