When you work every day with electrical panels, you learn quickly that a circuit breaker is not just a small black block that snaps into a load center. It is a safety device that protects people, cables, and expensive equipment. For many of us in the trade, GE breakers – now under the ABB umbrella – are a very common sight in residential, commercial, and industrial projects. But after the ABB acquisition and with so many model codes like THQL, THQP, Spectra, Record Plus, and WavePro on the market, choosing the correct GE breaker is not always simple.

In this guide I write as a practicing engineer from Asia, using practical, job‑site language. My English is not perfect, but I try to explain things in a simple and clear way, the same way I talk with technicians and contractors on site. We will walk through the main GE breaker types, how to read the model codes, what really fits a GE panel, and how to avoid dangerous mistakes with GE breaker compatibility. I will also connect this with the modern situation after ABB took over the GE Industrial Solutions business, because many professionals still ask who actually supports GE breakers today and whether ABB and GE breakers are interchangeable.

This article focuses on real‑world selection and compatibility questions: which breaker type (THQL or THQP) is correct for your Q‑Line panel, how to understand Spectra and Power Break molded‑case breakers, when you can use Eaton CL classified breakers as replacements, and which ratings and standards you must check to stay compliant with UL 489, UL 67, and IEC 61439. The goal is that after you finish reading, you can open a GE load center or switchboard, read the label with confidence, and select the right breaker without guessing.

If the information related to GE Breakers was interesting and informative to you, researching topic Types of Electrical Panels can be very engaging.

What Are GE Breakers? (Context & ge breaker types)

Owing to history, General Electric breakers — also called General Electric circuit breakers — have been one of the most recognized names in electrical equipment. For decades, GE circuit breakers have been installed in homes, commercial buildings, factories, hospitals, and data centers around the world. When somebody says “GE panel” or “GE breaker,” most electricians immediately imagine the familiar Q‑Line residential breakers or the larger molded‑case and power breakers used in switchboards.

However, the business structure behind these products changed in 2018, when ABB completed the acquisition of GE Industrial Solutions. This means that the old GE Industrial Solutions portfolio – including GE circuit breakers, panelboards, switchgear, and accessories – is now owned and supported by ABB. For professionals in the field, this is very important: when you replace GE breakers after the ABB acquisition, you are essentially working with an ABB‑managed product line, even if the breaker still carries a GE logo. Many professionals ask: are ABB and GE breakers interchangeable? The short answer is: they share a product lineage, but direct substitution still requires checking the official compatibility charts.

From a practical side, not much changes for installation rules. GE compatible breakers are still designed and tested according to UL 489 for molded‑case circuit breakers and UL 67 for panelboards. For global projects, assemblies must also comply with IEC 61439 and related standards. What changes mainly is where you get technical support, catalogs, and cross‑reference information. Today, ABB’s electrification websites and catalogs are the primary official sources for GE breaker data, especially for newer Spectra and Record Plus molded‑case breakers and for high‑capacity solutions like WavePro.

GE breaker types & Model Codes (Q-Line, Spectra, Power Break)

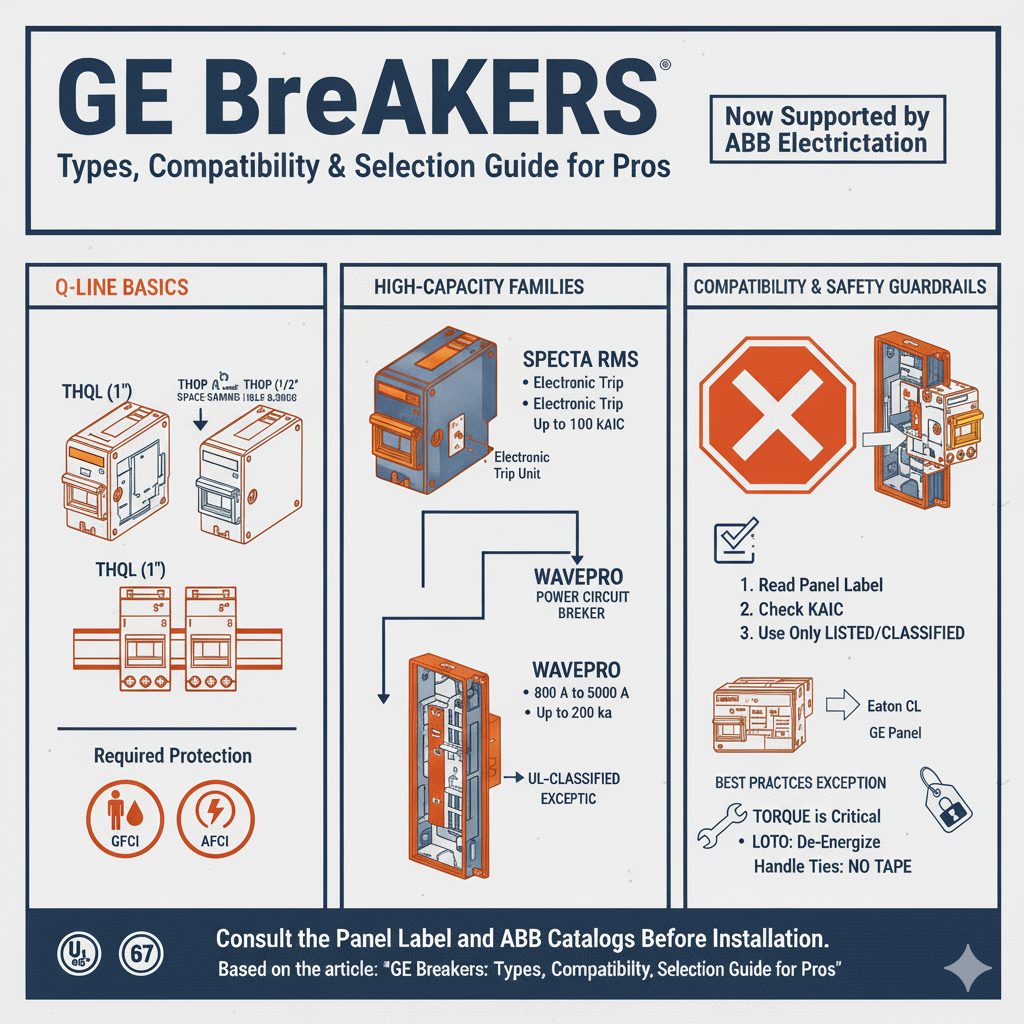

GE breakers are organized into several product families, each aimed at a different application range. Understanding the types of GE breakers and their typical prefixes allows you to quickly guess where a breaker belongs and what ratings to expect. These are the main GE circuit breaker types:

- Q‑Line plug‑in breakers for residential and light commercial load centers and panelboards.

2. E150 and other molded‑case circuit breakers (MCCBs) such as TEY, TQD, TED, and THED for commercial and industrial panels.

3. Advanced molded‑case and power breakers such as Spectra RMS, Record Plus, and WavePro for high capacity systems and switchgear.

Inside each family, the model code tells you more details: frame size, number of poles, interrupting rating, and sometimes special functions. For example, THQL and THQP are both Q‑Line breakers, but they have different widths and panel space behavior. Spectra breakers use frame designations like SE, SF, SG, and SK, and they can use electronic trip units such as MicroVersaTrip or microEntelliGuard. Record Plus uses frame names like FD, FE, FG, and FK, and offers both thermal‑magnetic and electronic trip units.

For many electricians, Q‑Line is the first of the GE breaker types they encounter. Q‑Line breakers are plug‑in devices for residential and light commercial load centers. They use thermal‑magnetic trip technology, meaning a bimetal strip for long‑time overload protection and a magnetic element for instantaneous short‑circuit trips.

Within the Q‑Line family you will commonly see these prefixes:

• THQL – standard 1‑inch wide plug‑in breakers for most GE load centers.

• THQP – thin, 1/2‑inch wide space‑saving breakers and tandems.

• THHQL – high‑interrupting versions, often with 22 kA interrupting capacity.

• AFCI/GFCI and dual‑function variants – breakers with built‑in arc‑fault or ground‑fault protection, or both.

THQL vs. THQP: What’s the Difference?

Because both THQL and THQP are Q‑Line breakers and their labels look similar, many people ask what is the real difference between THQL vs THQP. The main difference is physical width and therefore how they use panel space. Understanding the THQP vs THQL distinction is critical before making your selection.

THQL breakers are the standard full‑size Q‑Line option. Each pole is approximately 1 inch wide. A single‑pole THQL breaker, such as THQL1115 or THQL1120, takes one full slot in the panel. These breakers typically have 10 kA interrupting rating at 120/240 Vac, and they are the default choice for most general lighting and receptacle circuits in GE load centers. Their solid construction and large body make them comfortable to handle, and they are widely available from distributors and retail channels.

THQP breakers, on the other hand, are thin Q‑Line breakers, only 1/2 inch wide per pole. You can think of them as space‑saving versions. A THQP115 or THQP120, for example, allows two separate circuits to fit into the space of one standard breaker position when used as tandem or duplex designs, depending on panel approval. This is useful in panels where almost all spaces are already occupied, and you need to add one or two more circuits without replacing the entire load center.

However, there is an important caution: THQP breakers cannot be installed in just any GE panel. The panelboard label must explicitly state that thin breakers or tandem breakers are permitted and must indicate where they can be located. If the label does not mention THQP or tandem positions, you should stick with THQL standard breakers. Installing thin breakers in a panel not rated for them is a common mistake and can lead to overheating or code violations.

THHQL breakers are similar in physical size to THQL breaker, but they carry a higher interrupting capacity. For example, a THHQL1115 may be rated for 22 kA at 120 Vac. These are chosen when the available fault current at the panel is higher than 10 kA, such as in installations close to the utility transformer or in systems with large upstream equipment.

| THQL vs THQP — Key Differences at a Glance | MODEL |

|---|---|

| Standard full-size plug-in breaker | 1 inch wide per pole | Fits all standard GE Q-Line load centers | 10 kAIC interrupting rating (standard) | Suitable for all general branch circuits | THQL |

| Thin / space-saving breaker | 1/2 inch wide per pole | Only permitted where panel label explicitly allows tandem positions | Same amp ratings available but narrower form factor | THQP |

| High-interrupting version of THQL | 22 kAIC at 120 Vac | Same physical width as THQL | Selected when available fault current exceeds 10 kA | THHQL |

| Combined Arc-Fault + Ground-Fault protection | Required by NEC in many dwelling unit rooms | Available in THQL form factor | Higher cost but dual safety function in one device | THQL AFCI/GFCI Dual |

Spectra & Power Break at a Glance

When you move from typical load centers to larger distribution boards and switchboards, GE offers several molded‑case and power breaker families. Two of the most important are Spectra and Power Break. Understanding these GE breaker types is essential for commercial and industrial work.

Spectra RMS is a line of molded‑case circuit breakers that use electronic trip technology. Instead of a fixed thermal‑magnetic mechanism, they use interchangeable rating plugs and solid‑state trip units like MicroVersaTrip Plus, MicroVersaTrip PM, or microEntelliGuard. This makes them very flexible for commercial and industrial projects where precise protection curves and coordination with upstream and downstream devices are needed. Interrupting ratings can reach up to 100 kA at 480 V on some current‑limiting models. When comparing ABB vs GE breakers in this segment, Spectra is now the flagship ABB-supported line for legacy GE installations.

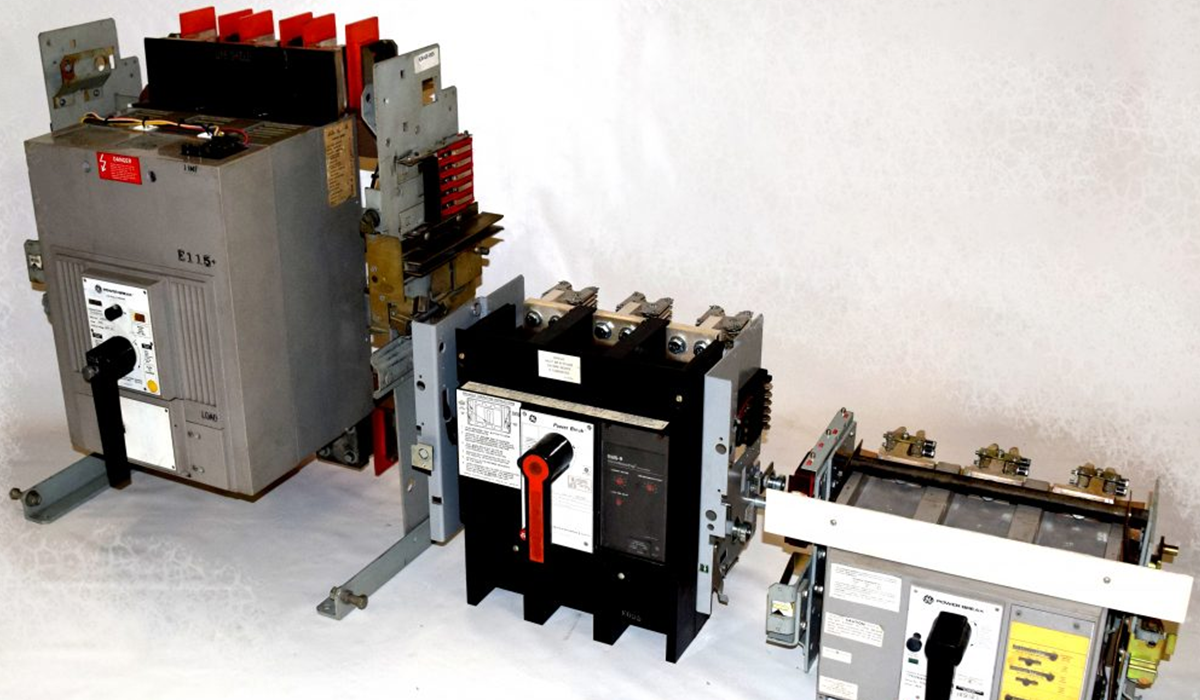

Power Break and WavePro are low‑voltage power circuit breakers used in switchgear and large switchboards. They cover current ranges roughly from 800 A to 5000 A and are designed to ANSI standards with high short‑time withstand capability. These breakers use draw‑out mechanisms, complex accessory packages, and often advanced trip units with communication and zone selective interlocking. They are not plug‑in replacements like Q‑Line; they belong to engineered assemblies where breakers, busbars, and enclosure are all tested together.

Further exploration of GE-Branded Residential Products can be found in the following recommended reading.

Compatibility & Replacement: What Breakers Are Compatible with GE

In everyday electrical work, one of the most sensitive questions is GE breaker compatibility. Many times, a contractor arrives on site, sees a GE panel, but the local shop has only Eaton or Siemens breakers in stock. It is tempting to try a different brand that seems to “click” into place. This is where we must be very strict: breakers are generally panel‑specific, and they are not freely interchangeable. Professionals frequently ask: what breakers are compatible with GE panels, and the answer always begins with the panelboard label.

From a safety and code point of view, a circuit breaker must be both mechanically and electrically suited for the panel. The National Electrical Code and UL standards require that the combination of panelboard and breaker is evaluated and listed together. If a breaker from another brand physically fits into the bus but is not listed or classified for that panel, the installation is not compliant and can be dangerous.

We can summarize the key idea in one sentence: physical fit is not the same as GE breaker compatibility. A breaker can snap into the busbar and hold in place but still fail during a high‑fault event because it was never tested with that panel’s geometry, bus thickness, or heat dissipation. If such a failure causes fire or damage, responsibility is usually on the installer, not on the breaker or panel manufacturer.

To select GE compatible breakers for a GE load center, follow these basic rules:

1. Read the panelboard label carefully. It lists the permitted breaker families, such as THQL or THQP, and sometimes specific catalog numbers.

2. Use only breakers that are either (a) listed by the panel manufacturer for that panel, or (b) UL‑Classified as suitable replacements for that exact panel type.

3. Do not mix brands unless a breaker is specifically UL‑Classified for use in that panel (for example, Eaton CL series in some GE panels).

4. When in doubt, consult the manufacturer’s GE breaker compatibility chart or contact technical support.

A common real‑world example is the relationship between GE panels and Eaton UL‑Classified CL series breakers. Eaton produces CL and CHQ breakers that are UL‑Classified as replacements for certain GE panels. These are the most common answer to the question of what breakers are compatible with GE when original GE units are unavailable. The CL breakers are tested in GE panels and appear in UL classification documents and Eaton cross‑reference charts. If the chart says that a specific CL breaker is accepted for a specific GE panel, then the AHJ (Authority Having Jurisdiction) will usually accept that combination. But if you pick a random Eaton BR breaker and put it into a GE panel without classification, you have no listing to support you.

For obsolete and discontinued equipment, such as older GE panels from the 1960s or 1970s, professionals often face more difficulty. Sometimes, the original breakers are no longer manufactured and only remanufactured or reconditioned units are available. In such cases, many engineers recommend considering panel replacement, especially when dealing with brands known for serious safety issues like Federal Pacific or Zinsco. Using old stablok‑style breakers that snap with thin stabs on the back bus is widely discouraged because of documented failure history.

| GE Breaker Compatibility Chart — Replacement Options | MODEL |

|---|---|

| Original GE Q-Line plug-in breakers | Listed by panel manufacturer | Always the first and safest choice | Full range 15–125 A, 1–2 pole | Available through ABB/GE distributors | THQL / THQP |

| UL-Classified replacement for specific GE panels | Must appear in official Eaton CL cross-reference chart | Not all GE panels are listed — always verify | Do NOT use standard Eaton BR series as replacement | Eaton CL / CHQ |

| Is GE and ABB breaker the same? ABB now owns the GE breaker line | ABB breakers compatible with GE legacy panels depends on model | Check ABB’s official cross-reference for each case | Same product lineage but not automatic interchangeability | ABB / GE (post-2018) |

| Siemens or other brands NOT classified for GE panels | Physical fit does NOT mean electrical compatibility | No UL listing supports the combination | Avoid unless a specific UL classification document exists | Non-listed brands |

Step-by-Step: Checking a Replacement

When you have to add a new circuit or replace a failed breaker in a GE load center, you can follow a simple but disciplined process:

- Identify the panel: Open the door and read the label. Note the manufacturer (GE), catalog number of the panel, and the list of acceptable GE breaker types. Look at an existing breaker and confirm its type code (for example, THQL or THQP).

2. Define the requirements: Determine the necessary amperage rating, pole count, and voltage. Also check if AFCI, GFCI, or dual‑function protection is required by the local electrical code for that circuit location.

3. Check interrupting rating (AIC): Estimate or obtain the available fault current at the panel. Select a breaker with interrupting capacity (for example, 10 kAIC or 22 kAIC) equal to or higher than that value.

4. Confirm conductor size and type: Make sure the breaker lugs are rated for the wire size and material (Cu or Al) you plan to use. Check the marking on the breaker body for acceptable range. For large assemblies, review our guide on copper vs. aluminum busbar selection as this affects your downstream connections.

5. If a GE breaker is not available: Consult UL‑Classified cross‑reference charts, such as Eaton CL documentation, to see if there is a classified replacement for your exact panel model. Only use it if the chart clearly lists your panel. This is the correct answer to “what breakers are compatible with GE” when originals are unavailable.

6. Document your choice: For inspections and future maintenance, it is good practice to record which breaker type you installed and why it is compliant. This is especially helpful for commercial jobs where AHJs are strict.

If the information on types of ge breakers was engaging and informative for you, gathering more knowledge about Beyond Breakers could be very exciting.

Common Pitfalls about ge breakers

On job sites, certain myths about GE breaker compatibility are repeated so often that some people start to believe them. Here are a few common pitfalls to avoid:

- “If it snaps in, it’s fine.” This is the most dangerous idea. Mechanical fit alone does not prove the breaker is tested for that panel.

• “All Eaton breakers fit GE panels.” In reality, only specific Eaton CL or CHQ UL‑Classified breakers are tested as replacements for specific GE panels. Standard BR breakers are not. This is one of the most common misunderstandings about GE compatible breakers.

• “Thin tandems always increase capacity safely.” Tandem or THQP breakers are only allowed where the panel label explicitly permits them. Overpopulating a panel with tandems can violate listing conditions and create overheating issues.

• “Brand does not matter if the amperage matches.” Brand and model absolutely matter, because the listing is for the combination of panel and breaker, not just the amp rating.

• “Are ABB breakers compatible with GE?” — This is a very common question. Because ABB breakers are the same product line as GE (post-2018 acquisition), some models overlap. But always verify with ABB’s official cross-reference. “Is GE and ABB breakers the same” has a nuanced answer: same company, but model-by-model verification is still required.

| GE Breaker Types — Complete Family Reference | MODEL |

|---|---|

| Residential & light commercial load centers | 15–125 A plug-in branch circuits | 10 kAIC (THQL) / 22 kAIC (THHQL) | Most common GE breaker type for homeowners and electricians | Q-Line (THQL / THQP) |

| Commercial / industrial MCCBs | SE/SF/SG/SK frames up to 1200 A | Electronic trip units (MicroVersaTrip / microEntelliGuard) | Up to 100 kAIC @ 480 V | Zone selective interlocking available | Spectra RMS |

| Global MCCBs for feeders & motor circuits | FD/FE/FG/FK frames up to 1600 A | Thermal-magnetic and electronic trip options | Strong current-limiting capability | IEC and UL markets | Record Plus |

| Low-voltage power breakers in switchgear | 800–5000 A range | Up to 200 kA rms sym. | Draw-out mechanism for maintenance | Zone selective interlocking & communication options | WavePro |

Ratings, Code & Standards You Should Know about ge breakers

Before selecting any GE breaker, you should be comfortable with the main electrical ratings and the standards that govern them. Reading the markings on the breaker body becomes much easier when you know what each value means.

The most important ratings are:

- Amperage rating: The continuous current the breaker is designed to carry, such as 15 A, 20 A, 100 A, or 600 A. This is normally printed on the handle.

• Voltage rating: The maximum system voltage at which the breaker is designed to operate, such as 120/240 Vac, 480 Vac, or 600 Vac.

• KAIC or interrupting rating: The maximum short‑circuit current (in kA) that the breaker can safely interrupt. Common values for residential breakers are 10 kAIC or 22 kAIC. For industrial MCCBs and power breakers, ratings can go up to 100 kA or even 200 kA.

• Poles: Number of poles (1‑pole, 2‑pole, 3‑pole) indicating how many conductors the breaker simultaneously protects.

Modern codes also require special types of protection in many circuits:

• GFCI (Ground‑Fault Circuit Interrupter) breakers protect people from ground‑fault shock by tripping on small leakage currents.

• AFCI (Arc‑Fault Circuit Interrupter) breakers protect mainly against fire by detecting series and parallel arcing conditions. For a detailed guide on how these devices work, see our article on arc fault breakers.

• Dual‑function breakers combine both AFCI and GFCI protection in one device. In many dwelling unit rooms, code allows or even prefers this option.

From a standards point of view, GE molded case breakers, including Q‑Line, Spectra, and Record Plus, are designed to UL 489. Panelboards they are mounted in must follow UL 67. For assemblies built for global markets, IEC 61439 defines the rules for low‑voltage switchgear and controlgear assemblies. For engineers working on international projects, it is normal to see both UL and IEC markings on the same equipment.

If the information on ge breakers was engaging and informative for you, gathering more knowledge about Rittal Electrical Panels could be very exciting.

Understanding GE PowerMark Gold Load Center Breakers

When it comes to electrical systems, choosing the right GE PowerMark Gold Load Center breakers is crucial for ensuring safety, reliability, and efficiency. GE PowerMark Gold breakers are designed for both residential and commercial use, offering a wide range of load center breakers to meet various electrical needs. These breakers provide superior protection against electrical faults, ensuring your system operates smoothly. Understanding the different types of GE PowerMark Gold breakers can help you make an informed decision, whether you’re upgrading your system or working on a new installation.

Further exploration of GE PowerMark can be found in the following recommended reading.

Choosing the Right Type of GE PowerMark Gold Breakers

The GE PowerMark Gold Load Center breakers come in various configurations, allowing for flexibility in managing electrical power. Whether you need standard GE PowerMark Gold breakers or more specialized models, selecting the right type ensures that your electrical system is both safe and efficient. These breakers are engineered for long-lasting performance and are compliant with industry standards, making them a reliable choice for electrical installations. By understanding the specifications and features of each GE PowerMark Gold breaker, you can optimize your electrical setup for peak performance and minimal downtime.

If the insights you gained from Type of GE PowerMark were intriguing and informative, exploring SIVACON Electrical Panel might be of great interest to you as well.

Selecting the Right GE Breaker (Checklist)

When you face a panel and need to choose a breaker, you can use the following checklist as a quick selection guide:

- Load type and current: Identify what the circuit will supply (lighting, receptacles, HVAC, motor, panel feeder) and calculate or estimate the full‑load current. Choose a breaker rating that matches or slightly exceeds this current according to NEC rules.

2. Voltage system and pole count: Confirm if the system is 120 V single‑phase, 240 V single‑phase, or 208/240/480/600 V three‑phase. Choose 1‑pole for 120 V circuits, 2‑pole for 240 V circuits, and 3‑pole for three‑phase circuits.

3. Panel type: Read the label and see which ge breaker types are allowed. For GE load centers, this is often THQL and possibly THQP. For commercial boards, check if TEY, TQD, Spectra, or Record Plus are specified.

4. Interrupting rating (AIC): Compare available fault current with breaker KAIC rating. If available fault current is high, select THHQL or higher‑rated MCCBs instead of standard 10 kA Q‑Line.

5. Special protection: Confirm if AFCI, GFCI, or dual‑function is required by code for that specific room or equipment.

6. Space constraints: If the panel is almost full and THQP thin breakers are permitted by the label, you may use them to add circuits. If not, consider panel upgrades instead of forcing more breakers in.

7. Coordination: For commercial and industrial systems, verify that downstream and upstream breakers coordinate so that a fault will trip the closest device and not shut down the whole facility. The switchboard busbar design also plays a critical role in this coordination.

Installation & Safety Best Practices

Even the best breaker will not perform correctly if it is installed poorly. A few basic habits make a big difference in reliability and safety when working with GE breakers or any other brand.

First, always de‑energize the system before installing or replacing breakers. Many experienced electricians can change a breaker “hot,” but the risk is high, especially in crowded panels with aluminum busbars and multiple conductors. As an engineer, I always recommend full lockout–tagout whenever possible, particularly in commercial and industrial boards.

Second, follow the torque specifications printed on the breaker or in the instructions. Loose connections can lead to overheating, nuisance tripping, or even fire. Over‑tightening can damage the conductor or the lug. Using a calibrated torque screwdriver or wrench is best practice, even if many technicians feel confident using their hands alone.

Third, verify that the breaker terminals are approved for the conductor material and size. Most modern GE Q‑Line breakers are marked Cu/Al and give a range like 14–8 Cu or 12–8 Al for 15–30 A models. For aluminum conductors, using an anti‑oxidant paste and proper wire brushing is a common requirement. In larger MCCBs like Spectra or Record Plus, check lug kits and bus connection hardware carefully. These breakers may have multiple lug options, copper or aluminum bars, and sometimes require phase barriers or backplates for higher voltages. To understand how busbars function in modern electrical systems, our dedicated guide covers the topic in depth.

Fourth, respect handle ties and common trip requirements. For multi‑wire branch circuits and two‑pole circuits, breakers must trip together when required by code. Double‑pole Q‑Line breakers include a common internal trip mechanism, while some single‑pole breakers may be joined with listed handle ties. Do not use tape or home‑made solutions instead of listed handle ties; inspectors do not accept this, and it is unsafe.

Finally, label all circuits clearly. Good panel schedules help future technicians, inspectors, and even yourself when you return to the job after several months. Poorly labeled panels cause confusion and can lead to accidental shutdown of critical loads during maintenance.

If the information related to Installation & Safety was interesting and informative to you, researching Underground Electrical Conduit can be very engaging.

Maintenance & Troubleshooting in GE breaker

Once a GE breaker is installed, it typically stays in service for many years. However, regular inspection and basic troubleshooting skills are necessary to keep systems safe and reliable.

During periodic maintenance, visually inspect breakers for signs of trouble: discoloration, melted plastic, cracks, corrosion at terminals, or strong smell of overheating. In Q‑Line panels, look for darkened bus stabs or signs of arcing under breakers that have been loose or overloaded. In Spectra or Record Plus MCCBs, inspect the line and load terminals, rating plugs, and trip units for dust buildup, contamination, or mechanical damage.

If a breaker trips repeatedly, do not simply reset it again and again. Try to determine whether the cause is overload, short circuit, ground‑fault, or arc‑fault. For AFCI and GFCI breakers, check if nuisance tripping is due to shared neutrals or wiring errors. Modern GE/ABB AFCI breakers are designed to reduce nuisance trips, but improper wiring can still cause them.

When a breaker needs replacement, the same ge breaker compatibility rules described earlier apply. Ideally, you replace a breaker with the same GE type and rating. If that exact model is unavailable, you may use a UL‑Classified replacement, such as Eaton CL, but only when the panel and breaker combination appears in the official chart. Always record the replacement in maintenance logs so that future technicians know why a certain breaker was installed.

If the information about Troubleshooting in GE breaker was valuable and interesting to you, researching Switchgear Secrets could be just as captivating.

GE Molded Case Breakers for High Capacity Systems (Spectra RMS, Record Plus, WavePro)

In larger commercial and industrial systems, simple plug‑in Q‑Line breakers are no longer enough. High capacity feeders and main breakers require GE molded case breakers with advanced protection features. GE, now ABB, offers several strong product lines for these applications: Spectra RMS, Record Plus, and WavePro. For all of these assemblies, the quality and sizing of the busbar arrangement inside the switchboard is equally important.

Spectra RMS breakers use electronic trip units and interchangeable rating plugs to set continuous current (In). For example, a K‑frame Spectra breaker may use a rating plug like SRPK1200A1200 to configure it for 1200 A. The trip unit can offer long‑time (L), short‑time (S), instantaneous (I), and sometimes ground‑fault (G) protection. More advanced MicroVersaTrip PM or microEntelliGuard units add features such as zone selective interlocking (ZSI), reduced energy let‑through modes, neutral protection, and detailed metering. These functions are very important when you want selectivity and arc‑flash mitigation in complex systems.

Record Plus molded‑case breakers are designed for global use and come in frame sizes like FD (up to 160 A), FE (up to 250 A), FG (up to 630 A), and FK (up to 1600 A). They support several trip unit families: thermal‑magnetic (LTM, LTMD, GTM) for standard overload and short‑circuit protection, Mag Break units for motor circuit protection where overload is handled by separate relays, and SMR selective electronic trip units that allow detailed adjustment of long‑time and short‑time settings. Record Plus breakers are also known for strong current‑limiting behavior, which helps reduce thermal and mechanical stress on downstream equipment during faults.

WavePro low‑voltage power circuit breakers sit at the top end of the capacity range, typically from 800 A to 5000 A. They are designed to ANSI switchgear standards and can have short‑circuit ratings up to 200 kA rms symmetrical depending on configuration. These breakers are usually draw‑out mounted, with positions such as disconnected, test, and connected, plus mechanical and electrical interlocks. Maintenance teams can withdraw a WavePro breaker for inspection or repair without powering down the entire switchgear lineup, which is a major advantage in critical facilities like data centers or process plants.

If you enjoyed learning about GE Molded Case Breakers, investigating 200 Amp Panel might also offer a similarly engaging and informative experience.

Conclusion

For all these high‑capacity breakers, correct installation of accessories is critical: neutral current sensors for ground‑fault protection, control power supplies (often 24 Vdc) for electronic trip units, voltage sensing modules, secondary disconnects, shutters, and phase barriers. If you work with this class of equipment, always use the manufacturer’s manuals and wiring diagrams, and document every modification for future service teams.

Choosing the right GE breaker—now backed by ABB’s expertise—is about more than just a “perfect click”; it’s about ensuring the long-term safety of your equipment and crew. From residential Q-Line units to heavy-duty Spectra and Record Plus models, making the right selection ensures your system remains compliant and rock-solid under fault conditions. Whether you’re researching GE breaker types, checking GE breaker compatibility, comparing THQL vs THQP, or asking “are ABB breakers compatible with GE” — this guide gives you the framework to make the right call on every project.

My brakes panel Put in 2001 it is a GE breaker panel, what other breaker is compatible . Putting in a garage heater 8500 watt using #8 AWG wire.

Want to put in a 40 amp. breaker.