Among the most important manufacturing methods used today, busbar metal stamping stands out as the gold standard for producing high-quality, dimensionally accurate busbars at scale. From progressive die stamping to precision punching and bending, every step of the stamping process plays a pivotal role in determining the final quality of the busbar. This comprehensive guide explores each of these processes in depth, explains the types of machines involved, and examines why metal stamped busbars fabrication are the preferred choice for engineers and manufacturers worldwide.

If you’d rather listen than read, feel free to play the audio file below for the rest of this article.

What Is Busbar Metal Stamping and Why Does It Matter?

Busbar metal stamping is a manufacturing process in which flat sheets or strips of conductive metal — typically copper or aluminum — are shaped, cut, punched, and formed using specialized stamping dies and presses. The result is a highly precise, repeatable component that meets strict dimensional tolerances required for safe electrical operation.

Unlike traditional machining or fabrication methods, busbar metal stamping offers several distinct advantages. It enables mass production of identical parts with minimal variation, reduces material waste through optimized die design, and significantly lowers per-unit manufacturing cost when producing at volume. More importantly, the precision achieved through stamping directly impacts the electrical performance of the busbar — poor dimensional accuracy can lead to improper contact, increased resistance, heat generation, and ultimately, system failure.

High-precision metal stampings are especially critical in LV switchgear applications, where busbars must fit within tightly engineered enclosures and connect seamlessly with other components such as circuit breakers, fuses, and terminal blocks. Even a deviation of a fraction of a millimeter can compromise the integrity of the electrical connection or prevent proper assembly. Understanding the common challenges in busbar fabrication is the first step toward avoiding these costly errors.

| Traditional Fabrication | Method |

|---|---|

| High — consistent tolerance across all parts | Dimensional Accuracy |

| Low — manual process limits output | Production Speed |

| Higher per-unit cost at volume | Unit Cost (High Volume) |

| Variable — operator-dependent | Surface Quality |

| Limited — difficult for complex geometries | Repeatability |

Progressive Die Stamping: The Backbone of High-Volume Busbar Production

Among the various stamping techniques available, progressive die stamping has emerged as the most efficient and cost-effective method for producing stamped busbars in large quantities. In this process, a metal strip is fed through a series of stamping stations, each of which performs a specific operation — such as piercing, notching, bending, or blanking — until the final part is complete.

The key advantage of progressive die stampings lies in their ability to perform multiple operations simultaneously within a single press stroke. This dramatically reduces cycle time and eliminates the need to move parts between separate machines. Each station in the progressive die is precisely engineered to carry out its assigned task without disturbing the work done by the previous station, ensuring that the finished busbar meets all dimensional and geometric specifications. To fully appreciate this workflow, it helps to understand the complete journey of busbar fabrication from raw material to finished conductor.

For busbar manufacturers, progressive die stamping is particularly valuable when producing parts with complex geometries — multiple holes at precise locations, intricate cutouts, or bends at specific angles. The progressive die maintains consistent accuracy across thousands or even millions of parts, making it ideal for high-volume production runs where quality cannot be compromised.

In addition to consistency, progressive die stamping also offers excellent material utilization. The die layout can be optimized to minimize scrap, which is particularly important when working with expensive copper — a material whose price fluctuations can significantly impact manufacturing costs. By maximizing the number of usable parts extracted from each strip of material, progressive die stamping helps manufacturers keep costs under control without sacrificing quality.

High-Precision Metal Stampings: Tolerances That Define Performance

When it comes to electrical components, precision is not merely a quality metric it is a safety requirement. High-precision metal stampings for busbars must adhere to tight tolerances that govern the thickness, width, hole diameter, hole position, and overall flatness of the finished part. These tolerances are typically specified in fractions of a millimeter and are verified through rigorous quality control processes.

The precision of a stamped busbar has a direct impact on several critical performance parameters. First, dimensional accuracy ensures that the busbar fits correctly within the switchgear enclosure and mates properly with adjacent components. Second, the quality of punched holes — their diameter, roundness, and positional accuracy — determines how securely mounting bolts and connectors can be tightened. A poorly punched hole can lead to loose connections, increased contact resistance, and localized heating that degrades both the busbar and the surrounding insulation. This is why busbar processing machine accuracy is so critical in transformer and switchgear production.

Third, the surface finish produced by high-precision metal stampings affects the quality of electrical contact at connection points. A smooth, burr-free surface ensures maximum metal-to-metal contact area, minimizing contact resistance and preventing the formation of oxide layers that can increase resistance over time.

| Specification Detail | Tolerance Parameter |

|---|---|

| ± 0.05 mm typical for stamped busbars | Thickness Tolerance |

| ± 0.1 mm for precision punched holes | Hole Position Accuracy |

| Ra 0.8–1.6 µm for contact surfaces | Surface Finish |

| ± 0.5° for CNC-controlled bending | Bend Angle Accuracy |

| Max 0.2 mm over 500 mm length | Overall Flatness |

The Indispensable Role of Busbar Machines in the Stamping Process

While progressive die stamping handles the production of high-volume, standardized busbar shapes, many applications require additional processing steps to transform the stamped blank into its final, installation-ready form. This is where dedicated busbar machines play an essential role. A thorough understanding of busbar fabrication machines and equipment suppliers is invaluable for manufacturers looking to build or upgrade their production line.

One of the key steps in busbar creation is shaping them into the required form. Here, the busbar bending machine is a crucial player. With its precise controls and robust construction, it enables operators to bend busbars accurately, without causing undue stress or damage to the conductor material. The busbar bender machine, on the other hand, is a specialized tool that allows for precise angle adjustments, ensuring the busbars fit perfectly within the LV switchgear without any gaps or misalignments. The global impact of busbar machines on switchgear panel quality cannot be overstated — precision at this stage directly determines system reliability in the field.

Bending a busbar is not as straightforward as it might appear. Copper and aluminum, while highly ductile, have specific bend radius requirements that must be respected to avoid cracking or thinning at the bend point. Modern busbar bending machines incorporate digital controls that allow operators to program specific bend angles, radii, and positions, ensuring repeatability across every part produced.

Types of Bending Machine Used in Busbar Manufacturing

Understanding the types of bending machine available is essential for any manufacturer looking to optimize their busbar production process. Different applications call for different machine configurations, and selecting the right type can significantly impact productivity, part quality, and tooling costs. For a deeper exploration of this topic, our comprehensive guide to busbar bending techniques covers every method in detail.

The most basic type is the manual hydraulic bending machine, which relies on operator skill and hydraulic force to perform bends. While suitable for low-volume or prototype work, manual machines introduce variability that is unacceptable in precision busbar production. For this reason, most professional busbar manufacturers use CNC-controlled bending machines that automate the positioning and bending process entirely.

CNC busbar bending machines offer several advantages over their manual counterparts. They can store and recall bend programs for specific busbar designs, eliminating setup time when switching between part types. Many modern CNC benders also include automatic angle measurement systems that verify each bend in real time and apply corrections if the measured angle deviates from the target. Knowing when to update or replace your busbar processing machines is equally important to maintaining these performance standards over time.

Electromagnetic bending machines represent the cutting edge of busbar bending technology. These machines use pulsed magnetic fields to form the busbar without direct mechanical contact, eliminating die marks and producing extremely clean, stress-free bends.

| Best Application | Machine Type |

|---|---|

| Prototyping and very low-volume custom work | Manual Hydraulic |

| Standard production runs, repeatable geometries | CNC Hydraulic |

| Complex 3D multi-plane busbar configurations | Multi-Axis CNC |

| High-purity, stress-free specialty busbars | Electromagnetic |

| Mid-volume production combining cut, bend, punch | 3-in-1 Processing |

Punching Machines: Precision at Its Best

Busbars, once shaped, need precise holes punched at specific locations for their installation within the switchgear. This is where the sheet metal punching machine comes into play. This machine provides high-precision, efficient punching, ensuring the busbars can be accurately and securely installed within the switchgear. The advent of automatic punching machines has significantly streamlined this process by reducing manual error and increasing efficiency. Harnessing advanced machinery for efficient busbar processing is now a competitive necessity rather than a luxury for modern manufacturers.

Modern CNC punching machines used in busbar production can execute complex hole patterns with exceptional speed and accuracy. Equipped with programmable punch heads and automatic tool changers, these machines can produce multiple hole sizes and shapes within a single setup, eliminating the time-consuming tool changes required by older manual punching equipment.

The quality of the punched holes is verified through vision-based inspection systems that check hole diameter, roundness, and position against programmed specifications. Any part that falls outside tolerance is automatically flagged and removed from the production stream, ensuring that only conforming parts advance to the next processing stage.

Busbar Layout: Engineering the Optimal Configuration

A critical aspect of busbar system design that directly influences the stamping and processing requirements is busbar layout. The busbar layout defines how individual bus conductors are arranged within the switchgear enclosure — their physical path, spacing, orientation, and interconnections. A well-designed busbar layout minimizes electrical losses, facilitates maintenance access, and ensures adequate clearance and creepage distances to prevent flashover. Engineers seeking a deeper understanding of this topic will find our comprehensive guide to busbar arrangements an essential reference.

From a manufacturing perspective, the busbar layout determines the shapes, bend angles, hole patterns, and dimensional tolerances that the stamping and bending processes must achieve. Complex layouts with multiple bends and precise connection geometries demand tighter process control and more sophisticated tooling than simple straight-run configurations. This is why close collaboration between electrical designers and manufacturing engineers during the busbar layout phase is essential.

Modern CAD tools allow designers to create detailed three-dimensional busbar layout models that can be used to verify clearances, check for interference between adjacent conductors, and simulate thermal performance under load. These models can also be used to generate the dimensional specifications that drive CNC bending and punching programs, creating a seamless connection between design intent and manufacturing execution. Enhancing productivity through operational excellence in metalwork begins at precisely this design-to-manufacturing handoff stage.

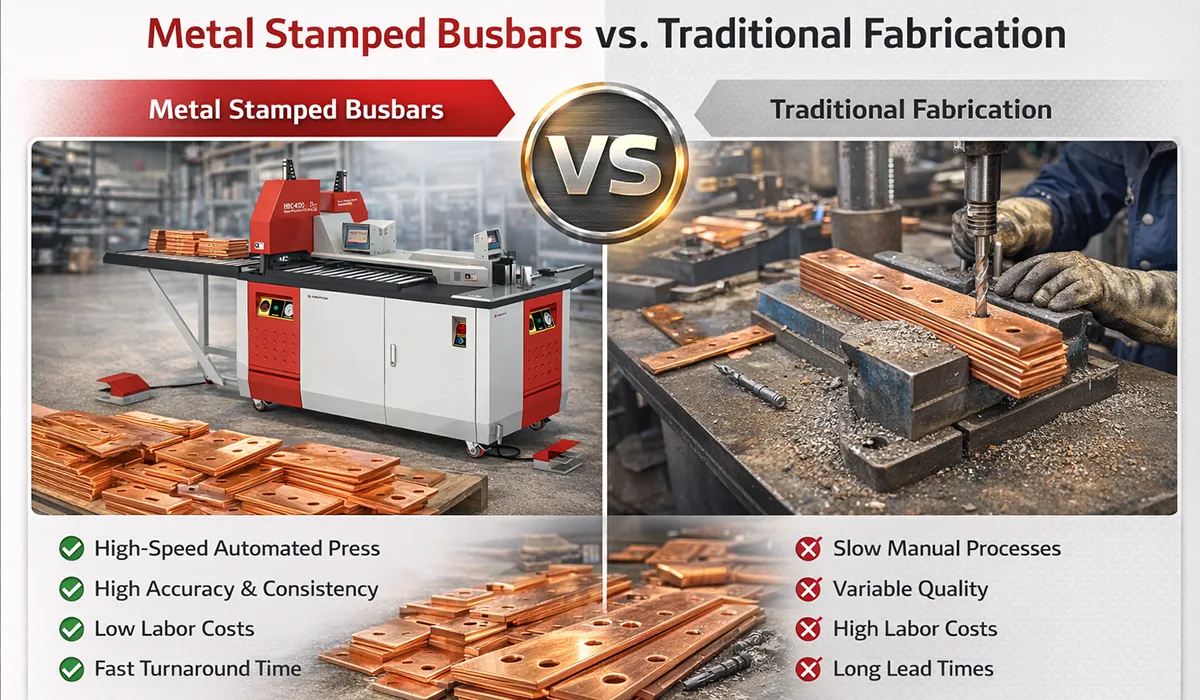

Metal Stamped Busbars vs. Traditional Fabrication

The question of whether to use metal stamped busbars or traditionally fabricated busbars is one that many switchgear manufacturers face when establishing or expanding their production capabilities. While traditional fabrication — which typically involves sawing, drilling, and hand bending — offers flexibility for low-volume or highly customized work, it struggles to compete with stamping on virtually every other performance dimension. Our overview of the main types of busbar fabrication machines provides a useful starting point for manufacturers evaluating their options.

In terms of dimensional accuracy, metal stamped busbars consistently outperform hand-fabricated parts. Stamping produces parts to tolerances that are difficult or impossible to achieve manually, particularly for hole positions and bend angles. This accuracy translates directly into easier assembly, better electrical connections, and higher overall switchgear reliability.

From a production efficiency standpoint, the advantage of stamped busbars is even more pronounced. A skilled operator can produce perhaps twenty or thirty fabricated busbars per hour working manually. A properly configured stamping and processing line can produce hundreds of finished busbars per hour, with substantially higher consistency and lower labor cost per part. Choosing the right supplier and equipment is equally critical — understanding the competitive advantages of leading busbar machine manufacturers can help procurement teams make better-informed sourcing decisions..

The Comprehensive Solution: 3-in-1 Busbar Processing Machines

The 3-in-1 busbar processing machine encapsulates the entire busbar creation process — bending, cutting, and punching — in a single, integrated platform. This all-in-one machine ensures accuracy and efficiency, making it an indispensable tool in the busbar production process. The ability to carry out multiple processes in a single machine not only reduces the space needed for separate machines but also increases productivity by eliminating part handling between operations. The benefits of combining multiple functions in a single busbar machine extend well beyond floor space savings — they fundamentally transform the economics and quality of busbar production.

From a quality standpoint, performing all operations on a single machine eliminates the positional errors that can accumulate when parts are moved between separate machines. Modern 3-in-1 busbar processing machines also offer sophisticated software interfaces that guide operators through the programming process and automatically calculate the optimal sequence of operations for each busbar design. For businesses evaluating the investment, a detailed busbar machine price guide is an essential reference for procurement managers building a business case.

Future Trends in Stamped Busbars and Metal Stamping Technology

The technology underlying busbar metal stamping continues to evolve rapidly, driven by the demands of an increasingly electrified world. The rise of electric vehicles and energy storage systems is creating demand for busbar designs with unprecedented current density and thermal management requirements. The shift toward lightweight conductors in these applications has also accelerated interest in the benefits of aluminum busbars as an alternative to copper in weight-sensitive designs.

Automation and artificial intelligence are also transforming busbar stamping operations. AI-powered vision systems can detect subtle surface defects that escape human inspection, while machine learning algorithms analyze production data to predict tool wear and optimize process parameters in real time.

Additive manufacturing is beginning to influence busbar production as well, primarily in the area of tooling. 3D-printed tooling inserts allow die designers to create complex geometries at reduced cost, opening new possibilities for busbar shapes and configurations — particularly for prototyping and short-run production of custom busbar designs.

Conclusion: Why Busbar Metal Stamping Is the Future of Power Distribution

The process of creating busbars for LV switchgears is a meticulous one, requiring precision, accuracy, and efficiency. The use of specialized machinery such as busbar bending machines, automatic punching machines, and busbar processing machines ensures that these requirements are met, contributing to the overall performance and safety of the LV switchgear.

From progressive die stampings that enable high-volume production of complex geometries, to high-precision metal stampings that meet the stringent tolerances demanded by modern switchgear designs, to the 3-in-1 processing machines that integrate bending, cutting, and punching in a single efficient workflow — busbar metal stamping represents the pinnacle of busbar manufacturing technology. Manufacturers who invest in the right equipment, maintain rigorous process discipline, and stay current with emerging technologies will be the ones who define quality standards in the global busbar industry for years to come.

Further exploration of Power Distribution can be found in the following recommended reading.