All low-voltage switchboards must be tested after manufacturing in the factory, and also after installation at site and before commissioning, in terms of dielectric properties, temperature rise, short-circuit withstand, continuity of protective circuits, clearances and creepage distances, the operation of mechanical components, and the degree of protection. Switchboard testing must be carried out based on the provisions of Clause 8 of Publication No. 1928 of the Institute of Standards and Industrial Research of Iran, as the test specifications. For example, a typical 400A main distribution board installed in a commercial building must undergo comprehensive testing before energization to ensure safe operation for critical loads like HVAC systems, lighting circuits, and emergency power distribution.

If the information on topic Testing Electrical Switchboards was engaging and informative for you, gathering more knowledge about low-voltage switchboards could be very exciting.

Types of Switchboard Testing Methods

There are two types of tests for switchboards:

- A) Routine test: A test that may be destructive for each product. These are typically performed on sample units during the manufacturing process.

- B) Basic test: A test that is normally performed on manufactured products so that the health of various parts of the switchboard in their normal operation is examined and confirmed. Every switchboard leaving the factory undergoes basic testing.

If you are looking for more information about Electrical safety testing, it is recommended not to miss reading this article.

Type 1 Test of the Switchboard

Impulse Voltage Test

Due to switching that occurs in the network, impulse voltages may occur in the network. For rated voltages: for 12 kV, a 75 kV test; for 24 kV, a 125 kV test; and for 36 kV, a 170 kV impulse test is performed. This test simulates lightning strikes or switching surges that can occur in power distribution systems, ensuring the switchboard insulation can withstand transient overvoltages.

Short-Circuit Current Withstand

Switchboards must withstand their rated short-circuit current. For instance, a switchboard rated for 50 kA short-circuit current must be able to handle fault currents up to this level without structural damage or fire hazard. This test ensures that busbars, connections, and enclosures remain intact during fault conditions.

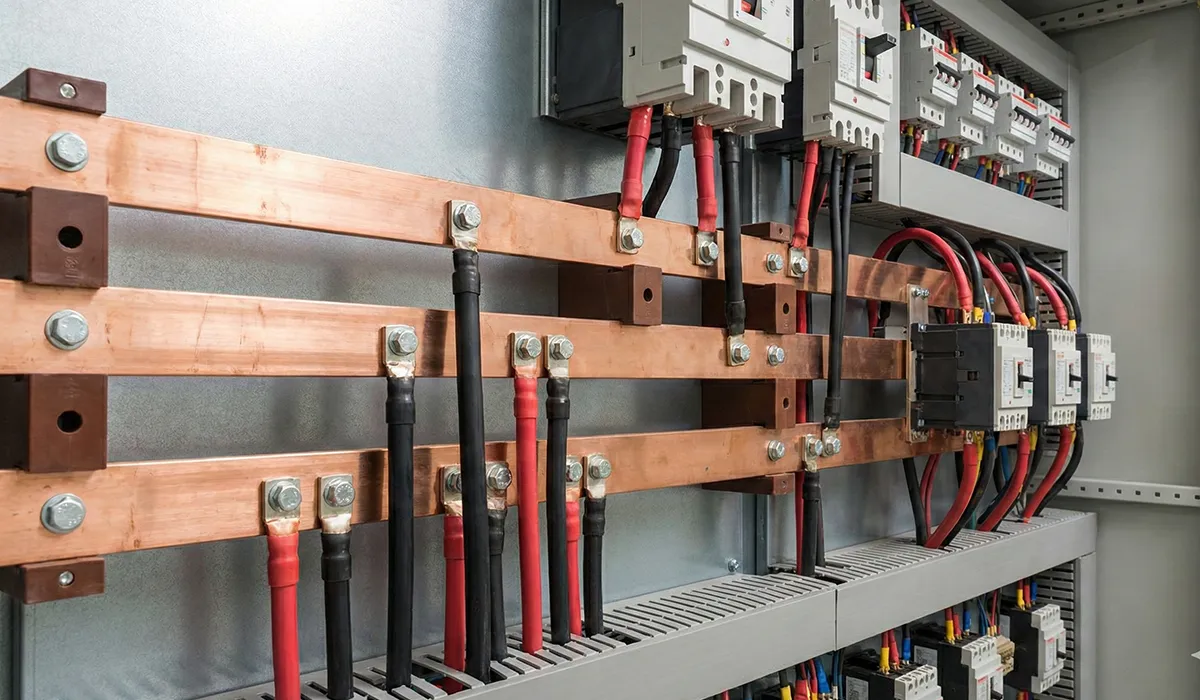

Temperature Rise Withstand Test

The temperature rise of busbars and connection points due to the passage of rated current must be within the values introduced in the standard. Typically, copper busbars should not exceed a temperature rise of 65 degrees Celsius above ambient temperature when carrying rated current continuously. For example, a 630A busbar system in a switchboard supplying power to industrial motors must maintain safe operating temperatures even during peak load conditions.

Arc Ignition Withstand Test

For any reason, an arc may occur between busbars or different phases inside the switchboard. This arc increases the air pressure inside the cell; if no actions are taken, the cell door may be torn off and other cell parts may be thrown outward. This test is not mandatory but is critical for personnel safety in high-risk environments like substations and industrial facilities.

For a comprehensive understanding of Arc Fault Breakers, we highly recommend reviewing this article.

Testing of Circuit Breakers and Disconnectors

- Impulse test

- Short-circuit current withstand

- Temperature rise at contacts or their connection points to the busbar

For each switching device or circuit breaker, a breakable short-circuit current is considered, so that a withstand current test is also performed. If, at a point along the path, a fault occurs while closing the switch, the switch must be able to withstand this current, which is usually 2.5 times the network short-circuit current. For example, if the system fault level is 25 kA, the circuit breaker must withstand a making current of 62.5 kA.

Basic Test

The basic test performed on most manufactured products is as follows:

A) General Inspections

Paint thickness, correct operation and integrity of door locks, correct adjustment of door gaps, switchboard degree of protection (IP), busbar color, completeness of bolts and nuts and correct selection of them, etc. For example, an IP54-rated outdoor switchboard must have properly sealed doors with gaskets intact, and all fasteners must be stainless steel or zinc-plated to prevent corrosion.

If you are looking for more information about topic IP54-rated outdoor switchboard it is recommended not to miss reading this article.

B) Mechanical Inspections

Correct operation of the switch and mechanical interlocks, inspection of insulators, continuity of the earthing system, smooth and correct movement of carriages, drawers, and other moving mechanisms, operation of drawer disconnectors. In a typical motor control center with 20 withdrawable contactors, each drawer must slide smoothly on rails and engage properly with the busbar stabs.

C) Electrical Inspections

Rated voltage and current, control circuit supply voltage, short-circuit current, correctness and quality of protective circuit implementation, electrical operation of all main switches, and the power-frequency test for the power circuit.

If the insights you gained from power-frequency test were intriguing and informative, exploring topic GE Breakers might be of great interest to you as well.

Switchboard Insulation Test

By insulation testing of electrical equipment, it is possible to detect insulation defects caused by mechanical damage, vibrations, excessive heat and cold, contamination, oil, moisture, and severe voltage changes. The devices used for insulation testing have the following specifications:

If the information about insulation testing of electrical equipment, was valuable and interesting to you, researching Crafting the Heart of Electrical Systems could be just as captivating.

5 kV Digital Insulation Test

This device is used to test the insulation of high- and low-voltage electrical equipment. A typical megohmmeter applies test voltages of 500V, 1000V, 2500V, or 5000V and measures insulation resistance in megohms. For a properly installed low-voltage switchboard, insulation resistance values should exceed 10 megohms between live parts and earth.

Protective and Measuring Tests

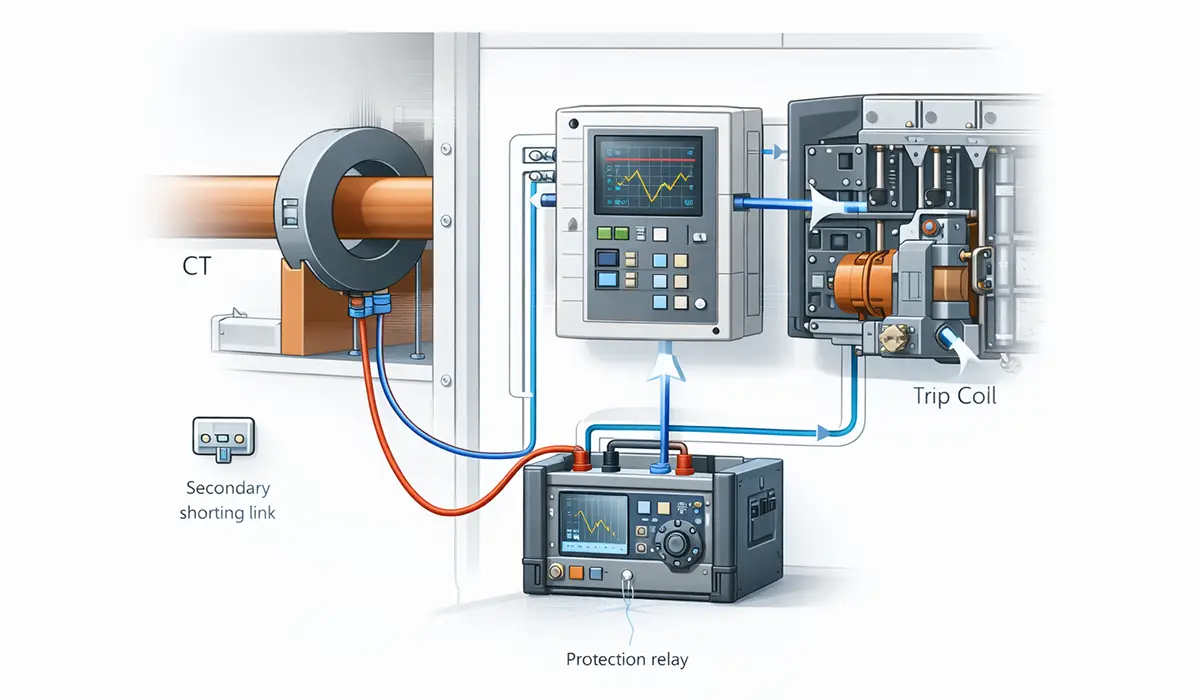

These tests are performed to check the performance of the protection system, including the current transformer and circuit breaker, or the voltage transformer and circuit breaker.

The measuring system test is performed to verify the performance of the current measuring system. A specified current is established using a primary current injection device and read through an ammeter. If the current transformer and ammeter are correctly selected and the connections are appropriate, the read value will be equal to the injected current value. For example, when injecting 100A through a 100/5A CT, the ammeter on the secondary side should read exactly 5A.

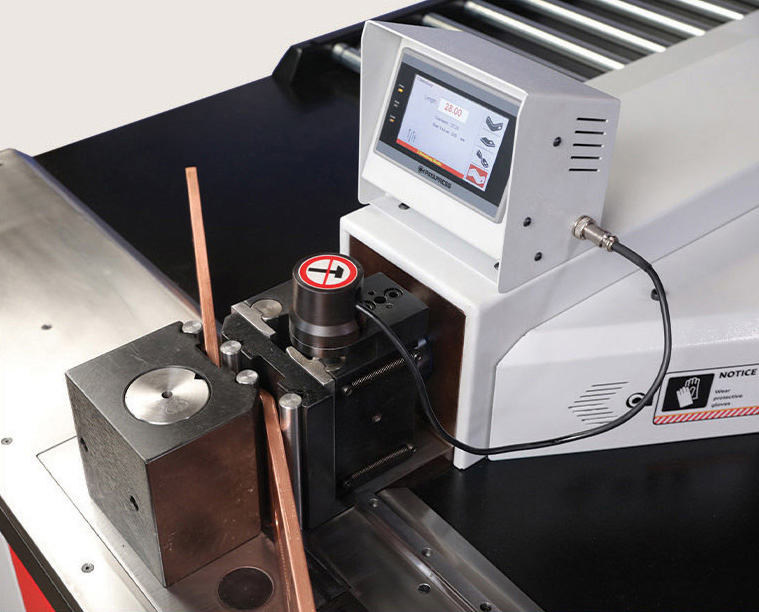

Primary Current Injection Test in the Switchboard

The primary current injection test in the switchboard is performed to check the performance of all components of the protection system. In this test, a high current is required for the operation of the protective device. The operating time of the protective relay is also measured. By performing this test, incorrect connection of the current transformer or incorrect relay setting can be identified.

The test of proper protection system performance, including the current transformer, relay, and circuit breaker, is carried out using a primary current injection device.

This test has several steps:

- Setting the relay overcurrent protection function

- Injecting primary current through the busbar box and increasing it from the relay setting system

- Recording the relay operating time

- Checking correct operation based on the relay setting system

By performing this test, any error in the current transformer connection, circuit breaker trip mechanism, or relay can be identified. For example, if an overcurrent relay is set to trip at 150A with a time delay of 0.5 seconds, the primary injection test should verify that when 150A is injected, the circuit breaker trips within the specified time window of 0.45 to 0.55 seconds.

For a comprehensive understanding of Fault injection, we highly recommend reviewing this article.

| Test Parameter | Specification | Example Value |

|---|---|---|

| Injection Current Level | 1.2 to 3.0 times rated current | 180A for 150A setting |

| Operating Time Tolerance | ±10% of set time | 0.45-0.55 seconds |

| CT Ratio Verification | Within ±3% error | 200/5A ±0.15A |

| Test Duration | Until trip occurs | Maximum 5 seconds |

| Minimum Test Repeats | 3 successful tests | 3 consecutive passes |

Dielectric Test on Auxiliary and Control Circuits of the Switchboard

In performing this test, the secondary windings of the current transformer must be short-circuited and isolated from earth, and the secondary windings of the voltage transformer must be opened. In the power-frequency voltage test on auxiliary and control circuits, a voltage of 2 kV is applied for one minute between the auxiliary and control circuits of the switching device. The test result is acceptable if no electrical discharge occurs. In most cases, for the insulation (dielectric) test of low-voltage switchboards, it is used in two sections: electrical circuits and busbar power circuits. In the first section, 1 kV is applied, and in the second section, 2.5 kV is applied for one minute.

If the material related to auxiliary and control circuits was both useful and intriguing to you, diving into Switchboard Busbar will likely be equally fascinating.

Switchboard Test by Measuring the Main Circuit Resistance

To measure the main circuit resistance, resistance measuring devices are used. The measured resistance shows the quality of the current path, and no range has been defined for it. However, as a general rule, busbar joint resistance should not exceed 5 microohms per connection. High resistance at joints indicates poor contact, which can lead to overheating during normal operation. For example, a poorly torqued bolted busbar connection might show 50 microohms instead of the expected 2-3 microohms, indicating the need for re-tightening or cleaning of contact surfaces.

Further exploration of busbar joint resistance can be found in the following recommended reading.

Mechanical Performance Test of the Switchboard

During the mechanical performance test of the switchboard, the main circuit has no voltage and current. This test is performed to ensure proper operation of the switching device and other movable parts, and mechanical interlocks. This test is performed five times, and no adjustments are made during them. In this section, proper switching of the switching device such as the breaker is ensured while supplying the switching mechanism with critical boundary voltages. By checking wiring correctness, compliance of the wiring with the diagram is confirmed.

Switchboard Measuring System Test

To ensure correct operation of the switchboard measuring equipment such as voltmeter, ammeter, wattmeter, varmeter, power factor, transducers, etc., this operation is performed. For this purpose, first the current- and voltage-generating devices are set, then applied to the measuring system according to the electrical drawings of the switchboards, and the measured voltage and current values are indicated by the measuring equipment. The set values indicate the correctness of the measuring systems, and if the measured values do not match the applied voltage and current values, corrective action is taken to remove the fault in the measuring system.

If the details you gathered about switchboard measuring equipment were interesting and insightful, you may find diving deeper into CUBIC Electrical Switchboard equally captivating.

Paint Thickness Control Test Using a Device on the Switchboard

The execution method is such that the device probe is placed at different points of the painted part and its thickness is measured. If the paint thickness is uniform on the part surface and matches the stated request, it is acceptable; otherwise, it is considered unacceptable and returned to the painting section.

Paint thickness control depends on their surface:

- Parts less than 10 square centimeters: one point

- Parts more than 10 square centimeters and less than 50 square centimeters: four points

- Parts with blind spots such as columns and frames: paint thickness is determined

Further exploration of Rittal Electrical Panels can be found in the following recommended reading.

RAL Control Test

The color of switchboards for each project is selected based on the RAL chosen by the employer or the project manager, and the color of parts must be matched with the RALMETER. For this purpose, one of the painted parts that has a hole with a diameter of 10 mm or similar is placed on the RALMETER, and no color difference should be observed. Common RAL colors for industrial switchboards include RAL 7035 (light gray) for panel bodies and RAL 9005 (jet black) for doors.

This test must be performed at the start of painting on the first part of each project by the QC inspector, and if a difference is observed, action must be taken to correct it. In selecting a switchboard, environmental conditions, installation requirements, and protection conditions must be considered.

Table of Standard Cross-Sections of Copper Conductors Related to Test Current

| Actual Rated Current Range (A) | Cross-Sectional Area (mm²) | Thermal Rated Current (A) |

|---|---|---|

| 0 – 7.9 | 1.0 | 6 |

| 7.9 – 15.9 | 1.5 | 8 – 10 |

| 15.9 – 22 | 2.5 | 12 |

| 22 – 30 | 4 | 16 |

| 30 – 39 | 6 | 20 |

| 39 – 54 | 10 | 25 |

| 54 – 72 | 16 | 32 |

| 72 – 93 | 25 | 40 |

| 93 – 117 | 35 | 50 |

| 117 – 147 | 50 | 63 |

| 147 – 180 | 70 | 80 |

| 180 – 216 | 95 | 100 |

| 216 – 250 | 120 | 125 |

| 250 – 287 | 150 | 160 |

| 287 – 334 | 185 | 200 |

| 334 – 400 | 240 | 250 – 315 – 400 |

Notes:

- The current magnitude must be greater than and less than, or equal to, the value mentioned in the first level and the value mentioned in the second level.

- These values are recommended standard currents that are stated only for information.

- The distance between two parallel bars related to one terminal should be approximately equal to 5 mm.

- If connecting the mentioned bars to the device under test is not possible, using a bar that has the same cross-sectional area and whose width is equal to the terminal width will be permitted.

- Using cable instead of bar will be permitted. The permissible cross-sections related to the cable are under review.

Measuring Transformer

Current Transformer

Current transformers are equipment that convert large and unmeasurable line currents into a smaller current so that both protection and measurement can be performed. In the medium-voltage class, current transformers are often of the Cast Resin type. The main components forming a current transformer are: primary winding, secondary winding, core, resin.

For example, a 200/5 A current transformer is a transformer that converts 200 A in the primary to 5 A in the secondary, which will be a suitable current for measuring or protective equipment. Standard values for secondary current are 1 A and 5 A. In a typical industrial application, a 600/5A CT would be installed on the main feeder of a factory where the normal load is 480A, providing 4A to the ammeter and protection relay.

The core characteristics of a current transformer for measuring and protective purposes are different from each other. The core of a single-core current transformer can be suitable either for measuring equipment or for protective equipment.

The main specification of each core is its accuracy class. Common accuracy classes for measuring cores are 0.2, 0.5, and 1, which are specified as 0.2M5, 0.5M5, and 1M5. This means that our equipment will have, respectively, 0.2%, 0.5%, and 1% error at 5 times the rated current. Common accuracy classes for normal protective cores are 5P10, 10P10, and 5P15. For example, accuracy class 5P10 means that the transformer will have a 5% error at 10 times the rated current. For cores required for differential protection, the accuracy class is often 5P20, and their output power is 20 VA or more.

Example CT Nameplate Data:

- Ratio: 300/5-5A

- Core 1: CL 0.5, 10VA

- Core 2: 5P10, 10VA

In general, measuring equipment is selected based on rated current and does not have the ability to pass currents up to several times the rated current.

Effect of Thermal Current Ith

The amount of thermal current directly affects the cross-section of primary and secondary copper, and therefore creates a considerable effect on the transformer price. This effect is greater on the copper used in the secondary because the length of the secondary copper conductor has a very large number of turns. For instance, a CT rated for 1000A continuous thermal current will require significantly more copper in its windings than one rated for 400A, potentially doubling the material cost.

For a comprehensive understanding of secondary copper conductor, we highly recommend reviewing this article.

Voltage Transformer

Voltage transformers, like current transformers, reduce the voltage quantity in the power circuit to a level that is measurable and comparable for protective purposes. Unlike current transformers whose core characteristics are completely different depending on use in the measuring or protective circuit, protective and measuring cores of voltage transformers do not differ much from each other.

If the content on Voltage transformers was interesting and insightful to you, continuing to explore Supercapacitor could be both exciting and beneficial.

Therefore, a voltage transformer with accuracy class 0.5 can both provide a correct reading and be suitable for overvoltage or undervoltage protection. This is because voltage fluctuations in the network are very low (+0.5% to -0.5%). Voltage transformers can be connected between phase and earth or phase and phase. For example, a typical VT might have a ratio of 11000V/110V, stepping down the primary voltage by a factor of 100 for safe measurement and protection.

| Transformer Type | Accuracy Class (Measuring) | Accuracy Class (Protection) | Typical Application |

|---|---|---|---|

| Current Transformer (CT) | 0.2, 0.5, 1.0 | 5P10, 5P20, 10P10 | Metering and overcurrent protection |

| Voltage Transformer (VT) | 0.5, 1.0 | 3P, 6P | Voltage measurement and under/overvoltage protection |

| CT for Differential Protection | Not applicable | 5P20, Class X | Transformer and busbar differential protection |

Conclusion

Low-voltage switchboards must be tested both after factory assembly and after site installation before commissioning, covering dielectric performance, temperature rise, short-circuit withstand, mechanical operation, protection continuity, and IP degree of protection. The text outlines routine (potentially destructive) and basic (production) tests, and explains key procedures such as insulation testing, primary current injection for protection verification, and dielectric tests on auxiliary/control circuits. It also includes practical QC checks for paint thickness and RAL color matching, plus reference values for conductor cross-sections and measuring transformer accuracy classes. For reliable operation, these tests should be performed according to the specified test requirements and documented carefully.

Frequently Asked Questions

What are the two main categories of switchboard tests?

Routine tests (which can be destructive and are performed on sample units) and basic tests (performed on all manufactured products to verify proper operation before delivery). Learn more about electrical panel types and testing.

Why is the primary current injection test important?

It verifies the complete protection system performance including CT connections, relay settings, and circuit breaker trip mechanisms, ensuring the system will operate correctly during fault conditions.

What is acceptable insulation resistance for a low-voltage switchboard?

Insulation resistance should exceed 10 megohms between live parts and earth when tested at appropriate voltage levels (typically 500V to 1000V for low-voltage equipment).

How many times is the mechanical performance test performed?

The mechanical performance test is performed five times consecutively without making any adjustments during the test runs to ensure consistent operation.

What are common CT accuracy classes for measuring and protection?

Measuring cores typically use Class 0.2, 0.5, or 1.0 (e.g., 0.5M5), while protective cores use 5P10, 10P10, or 5P15, with differential protection often using 5P20.

What voltage is applied during the dielectric test on auxiliary circuits?

A voltage of 2 kV is applied for one minute between auxiliary and control circuits, with no electrical discharge indicating a successful test result.

What should busbar joint resistance typically not exceed?

Busbar joint resistance should not exceed 5 microohms per connection, with values of 2-3 microohms being typical for properly installed connections.